Method for preparing non-homogenous parts by deposition

A non-homogeneous, layered technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of complex preparation process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

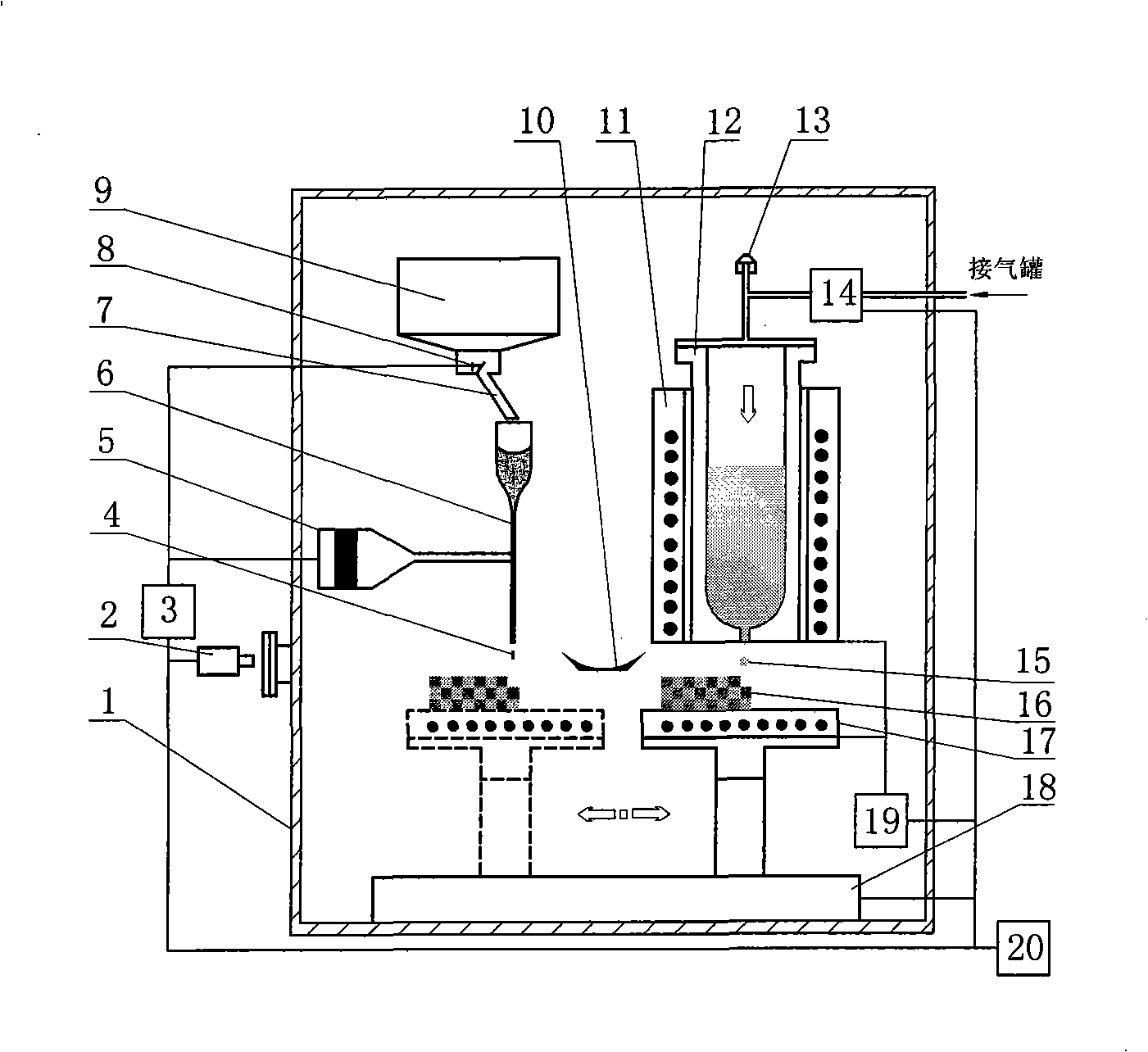

[0017] Embodiment 1: with reference to accompanying drawing. Put the Al profile into the crucible 12, put the Ti powder into the powder hopper 9, and seal the powder hopper 9.

[0018] After evacuating the vacuum chamber 1, fill it with argon gas to keep the pressure in the vacuum chamber 1 consistent with the atmospheric pressure, and cycle twice to make the oxygen content below 10ppm, so as to prevent the Al profile from being oxidized after heating and melting.

[0019] Turn on the vibration powder feeding control module 3, turn on the powder delivery control switch 8, so that Ti powder enters the capillary 6 through the powder delivery tube 7; when there is less powder in the capillary 6, turn on the powder delivery control switch 8 again to supplement the capillary 6 pink. Start the ultrasonic transducer 5 to apply vibration to the capillary 6, so that the powder is filled with the capillary 6 and the powder can be fed stably, then the vibration is stopped, and the powde...

Embodiment 2

[0029] Example 2: SiC p Preparation of Mg-based composite parts locally reinforced by particles.

[0030] It is required to prepare SiC with the heights of the upper, middle and lower sections being 10mm respectively and the weight percentage of each section's reinforcement is different. p / Mg composite material, where the upper and lower ends of SiC p The volume percentage of the reinforcement is 15%, and the middle part is SiC p The volume percentage of reinforcement is 10%. Three-dimensional modeling is performed according to the geometric size and material information of the part to generate two-dimensional layer data. The thickness of the layer is still 100 μm, so the number of layers in each segment is 100. Then, according to the level data, the numerical control code of substrate movement and the switch control signal of droplet and powder ejection are generated.

[0031] Put the Mg profile into the crucible 12, put the SiC p The particles are put into the powder h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com