Method and device for casting electromagnetic compound control electroslag remelting fine grains

A technology of electroslag remelting and electromagnetic compounding, which is applied in the field of metal material preparation, can solve the problems of insignificant structure refinement effect, high working current and working voltage, and difficult implementation of the core of the ingot, and the strength of the magnetic field will not be weakened. , low working frequency, and the effect of improving the refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

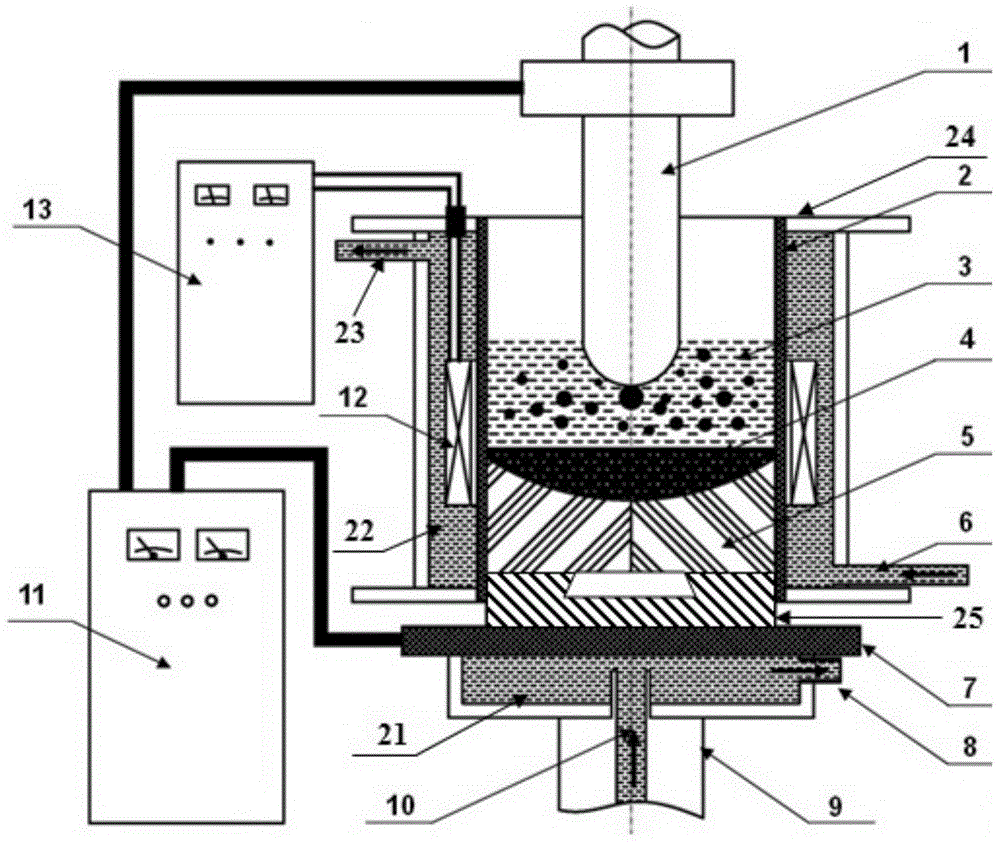

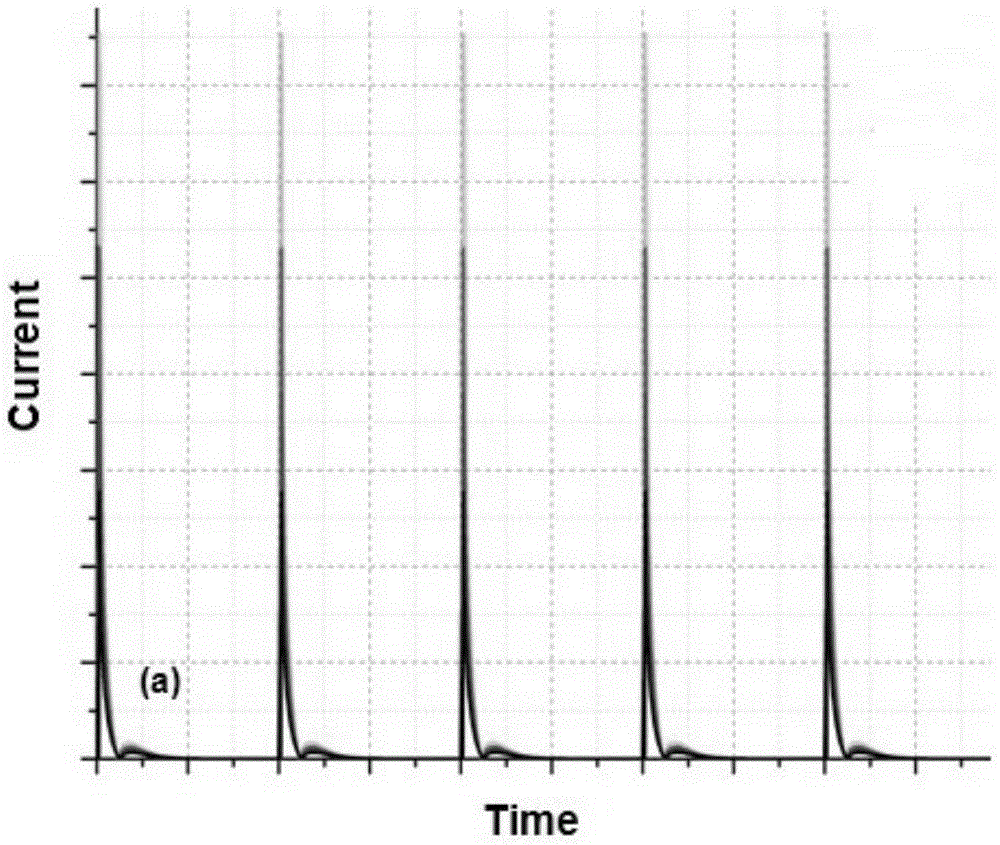

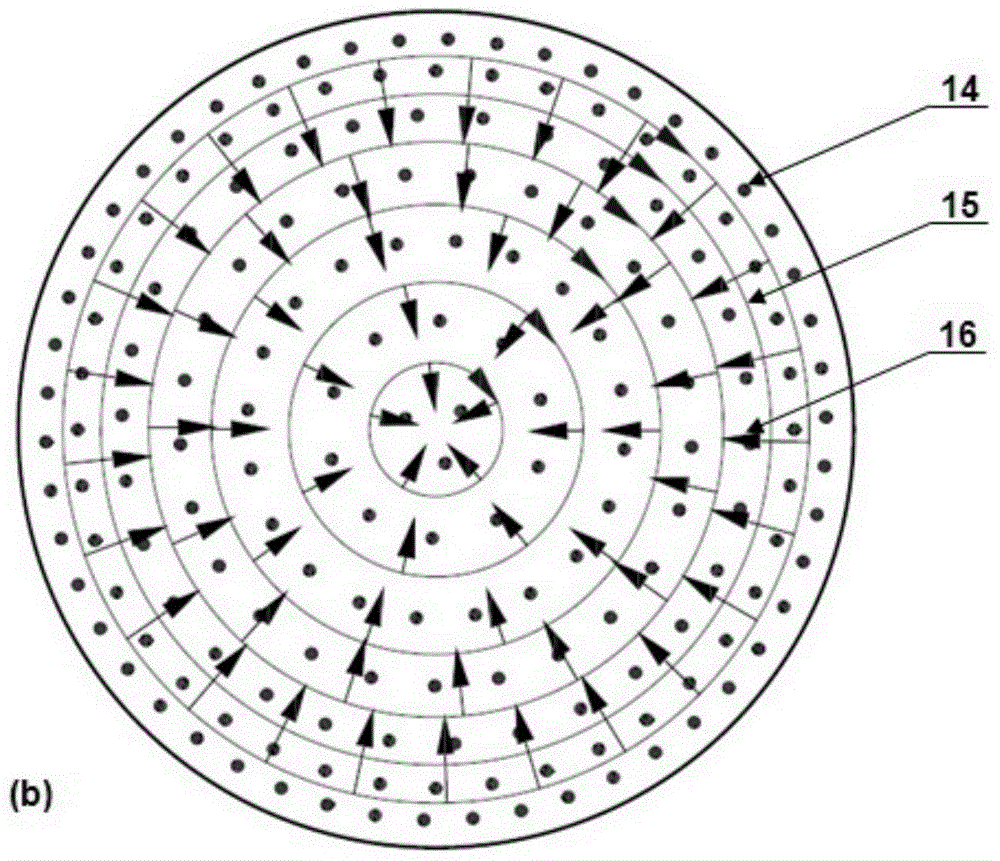

[0050] In this embodiment, the electroslag remelting alloy is H13 high-alloy steel, and the electroslag uses 70% CaF 2 , 15% CaO and 15% Al 2 o 3 , the working current is 10000A, and the inner diameter of the crystallizer is The interface temperature between electrode and slag can reach up to 1900℃~2000℃, and the temperature of slag surface is generally about 1400℃~1800℃. When one end of the consumable metal electrode is inserted into the slag, the consumable metal electrode, slag pool, metal molten pool, lead The ingot and the red copper electrode plate can form a circuit through the wire and the electroslag remelting working power supply. During the electrification process, the slag pool releases Joule heat, which gradually melts the consumable metal electrode end, and the molten metal gathers into liquid droplets and passes through the slag. The pool falls into the crystallizer to form a molten metal pool. Turn on the pulse power supply, the pulse voltage is 120-200V, t...

Embodiment 2

[0052] In this embodiment, the electroslag remelting alloy is H13 high-alloy steel, and the electroslag uses 70% CaF 2 , 15% CaO and 15% Al 2 o 3 , the working current is 13000A, and the inner diameter of the crystallizer is The interface temperature between electrode and slag can reach up to 1900℃~2000℃, and the temperature of slag surface is generally about 1400℃~1800℃. When one end of the consumable metal electrode is inserted into the slag, the consumable metal electrode, slag pool, metal molten pool, lead The ingot and the red copper electrode plate can form a circuit through the wire and the electroslag remelting working power supply. During the electrification process, the slag pool releases Joule heat, which gradually melts the consumable metal electrode end, and the molten metal gathers into liquid droplets and passes through the slag. The pool falls into the crystallizer to form a molten metal pool. Turn on the pulse power supply, the pulse voltage is 120-200V, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com