Preparation device and method for superfine metal powder

A technology of ultra-fine metal powder and preparation device, which is applied in the field of 3D printing, can solve the problems of metal powder particle size and sphericity, and achieve the effects of good fluidity, high sphericity, and low consumption of inert gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

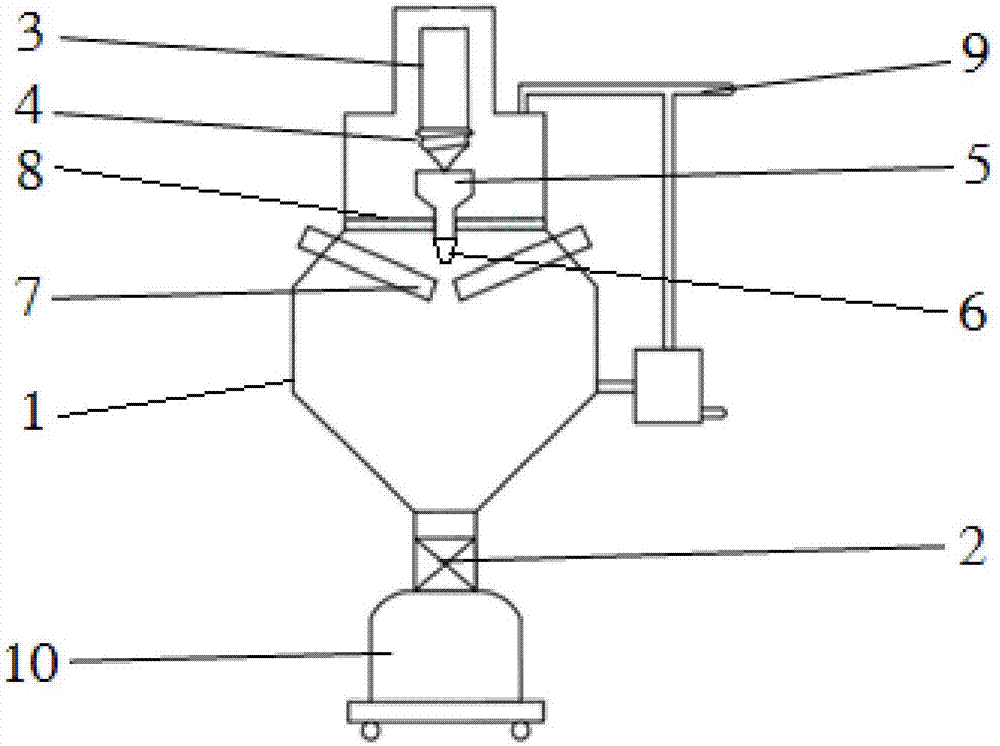

[0042] A kind of structure of the preparation device of ultrafine metal powder of the present invention is as figure 1As shown, the lower part of the housing 1 is provided with an openable isolation plate 2, which divides the housing into upper and lower spaces. The uppermost part of the upper space is provided with a metal fixing device. The metal fixing device adopts a clamping device (not shown in the figure) to clamp and fix the tapered end of the metal rod 3 downward vertically. The tapered end of the metal rod Metal droplets are formed by heating with a heating device arranged below the clamping device, and the heating device adopts an induction coil 4 surrounding the tapered end of the metal rod. Just below the conical end of the metal bar 3 (that is, just below the induction coil 4) is provided with a centrifuge 5, the centrifuge 5 is a centrifuge, and the centrifuge adopts a funnel-type structure with an upper opening and a lower opening, and its upper opening is alig...

Embodiment 1

[0053] This example is a preparation process of tantalum (Ta1) powder for spherical metal powder 3D printing, and the chemical composition of Ta1 is shown in Table 1.

[0054] Table 1 Chemical composition of Ta1

[0055]

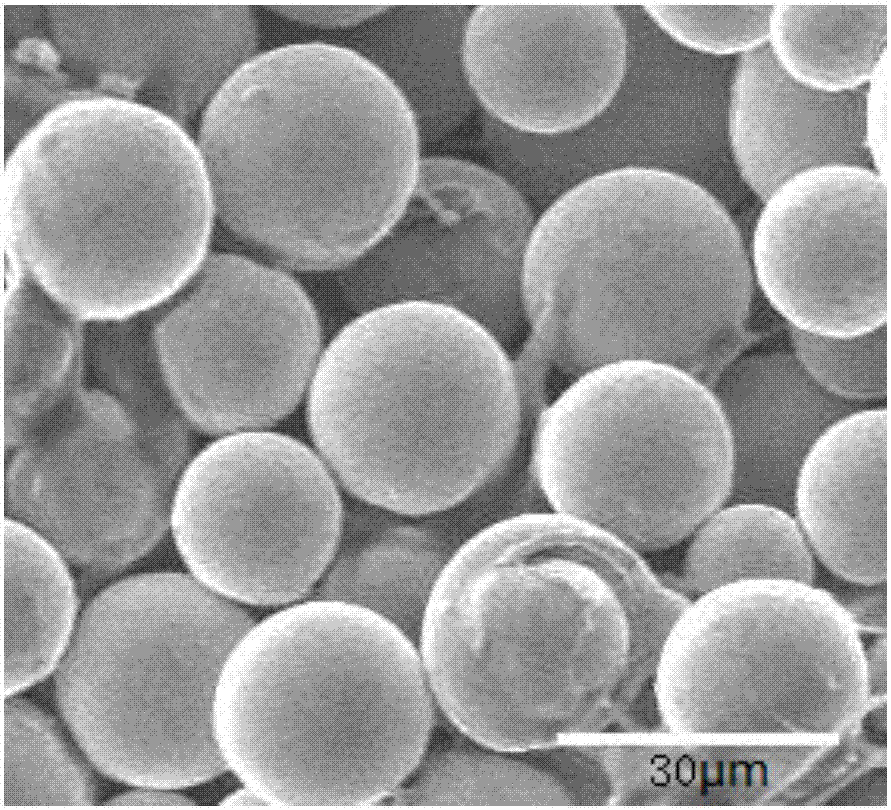

[0056] The specific operation is: remove the oil stain and oxide layer on the surface of the tantalum rod, fix it in the heating area, turn on the argon gas system and the heating system, and heat the tantalum rod to form a molten liquid. The molten liquid was dropped into a centrifugal device with a rotating speed of 1300r / min and centrifuged for 1min. In the process of heating and centrifuging, turn on the hot gas device in advance, adjust the angle between the axis of the gas ejection device and the center line of the metal bar to be 45°, so that the temperature of the ejected argon gas is 350°C, and the pressure is kept at 2MPa~3MPa . After centrifugation, the thin layer of molten liquid droplets falling along the guide tube is broken and atomized i...

Embodiment 2

[0058] This example is a preparation process of tantalum (Ta1) powder for spherical metal powder 3D printing, and the chemical composition of Ta1 is shown in Table 2.

[0059] Table 2 Chemical composition of Ta1

[0060]

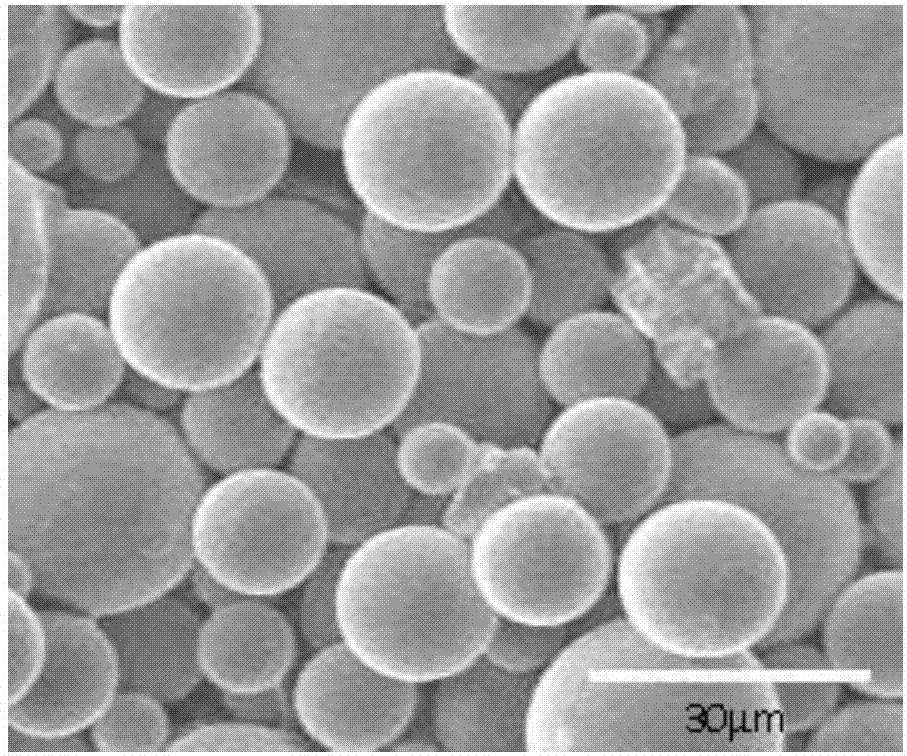

[0061] The specific operation is: remove the oil stain and oxide layer on the surface of the tantalum rod, fix it in the heating area, turn on the argon gas system and the heating system, and heat the tantalum rod to form a molten liquid. The molten liquid was dropped into a centrifugal device with a rotating speed of 1200r / min and centrifuged for 1.5min. In the process of heating and centrifuging, turn on the hot gas device in advance, adjust the angle between the axis of the gas ejection device and the center line of the metal bar to be 45°, so that the temperature of the ejected argon gas is 300°C, and the pressure is kept at 3MPa~4MPa . After centrifugation, the thin layer of molten liquid droplets falling along the guide tube is broken and atomized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com