Method for preparing flaky metal powder

A flake metal and powder technology, which is applied in the field of flake metal powder preparation, can solve problems such as the inability to continue the preparation and the adhesion of the metal drop tank wall, so as to avoid secondary processing and poor adaptability, short process cycle and high powder quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

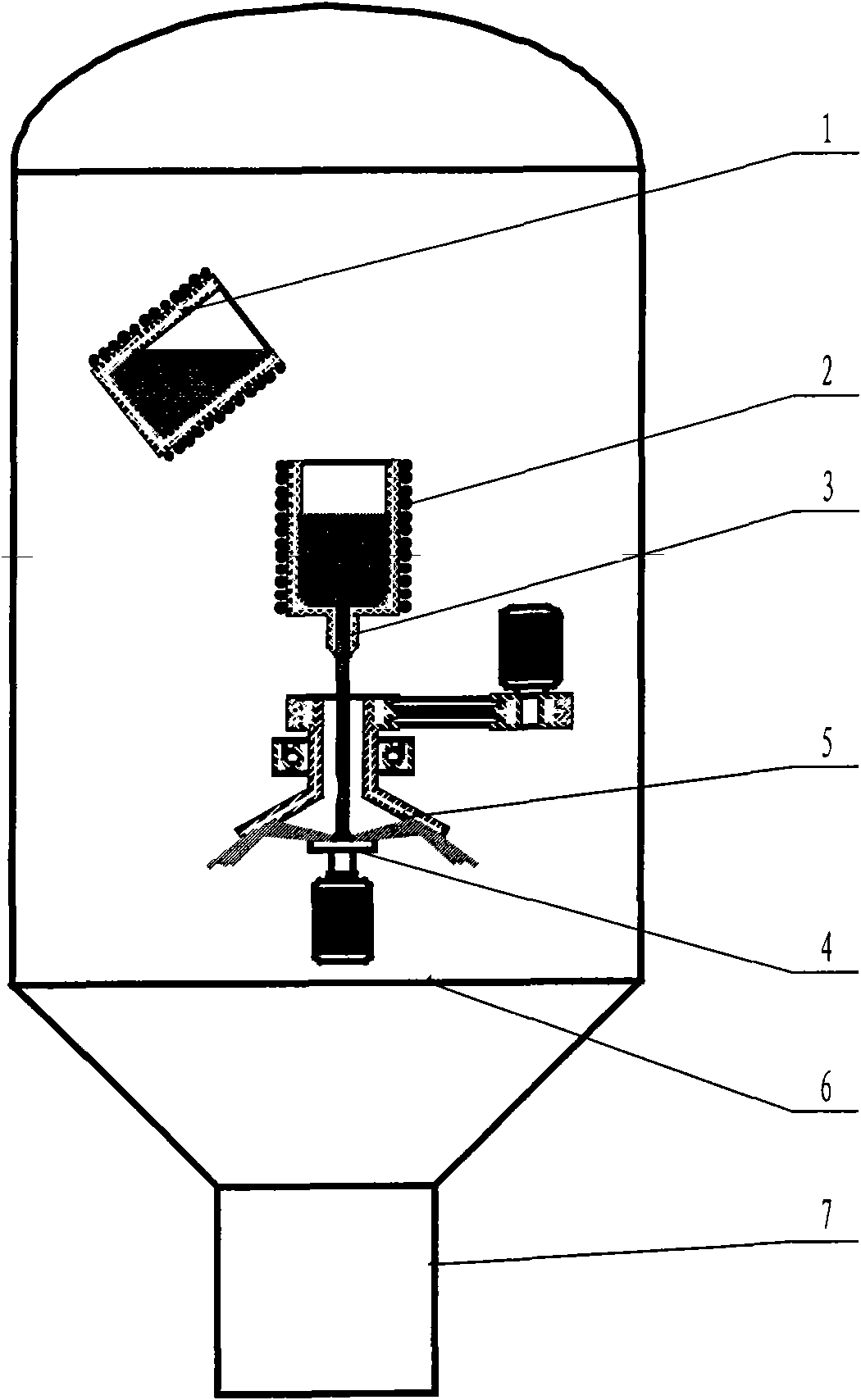

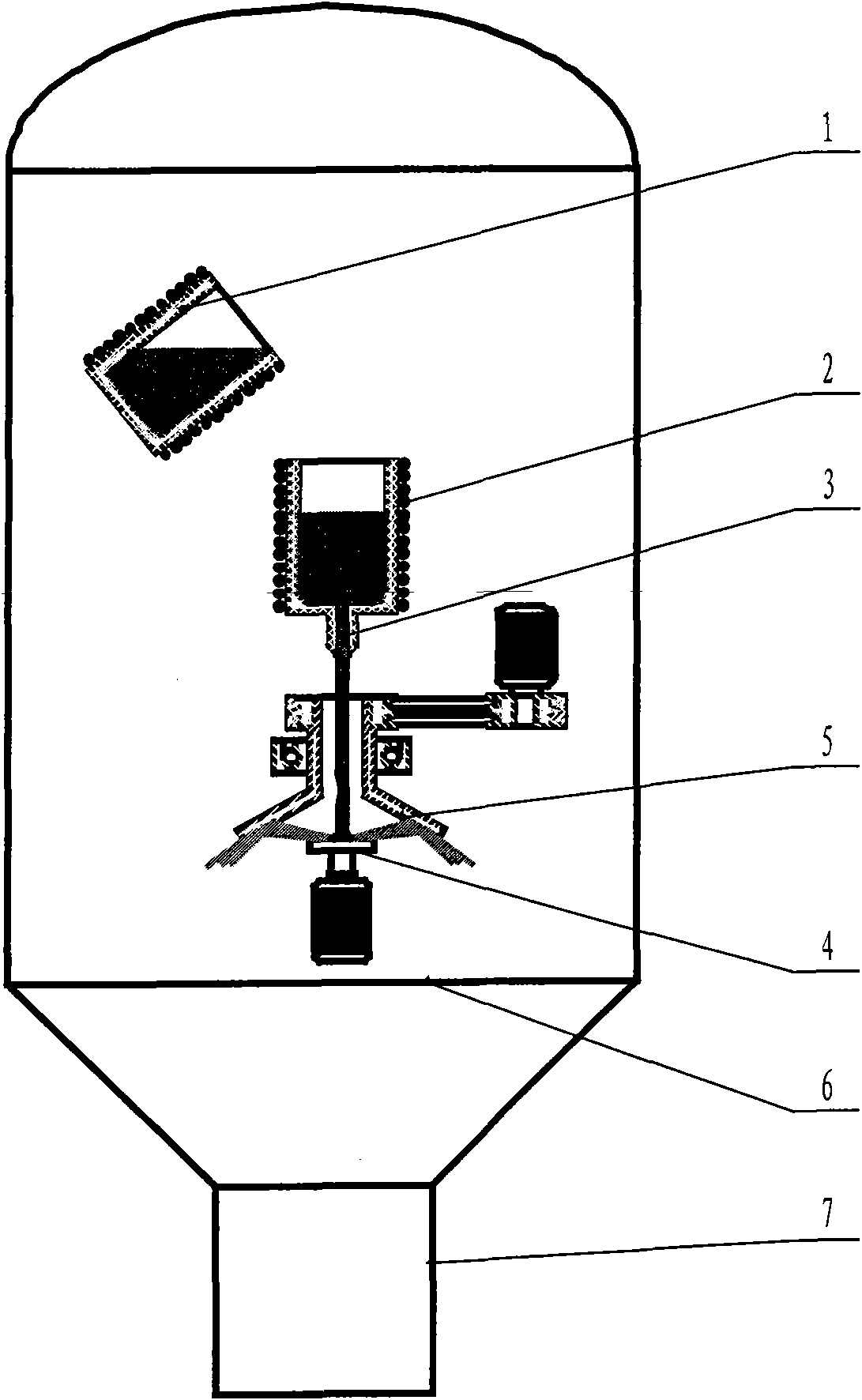

[0026] Such as figure 1 Shown is a schematic diagram of the process of preparing flake metal powder in the present invention. Among them, a melting crucible 1, a tundish crucible 2, a nozzle 3, a rotary atomizer 4, a water-cooled roller 5, an atomization chamber 6, and a powder collection tank 7.

[0027] Take 15 kg of metal tin and put it into the melting crucible 1; vacuumize the atomization chamber 6 to -0.1MPa, and then fill it with high-purity argon with a pressure of -0.07MPa. Put metal tin into the melting crucible 1, use resistance heating, melt and overheat and keep warm to 600°C, start and adjust the rotation speed of the rotary atomizer 4 to 5000 rpm, rotate clockwise, and the rotation speed of the water-cooled copper roller 5 to 1000 rpm Rotate counterclockwise; pour the metal melt into the tundish crucible 2, and the melt flows out from the nozzle 3 at a flow rate of 20 g / s. Impact deformation into flake powder. The flaky powder has a round and bright appearanc...

Embodiment 2

[0029] Take 20 kg of metal aluminum and put it into the melting crucible 1; vacuumize the atomization chamber 6 to 10-20Pa, and then fill it with high-purity argon gas with a pressure of 0.1MPa. Put metal aluminum into the melting crucible 1, use medium frequency induction heating, melt and overheat and keep warm to 800°C, start and adjust the rotation speed of the turntable atomizer 4 to 20000 rpm, rotate clockwise, and the rotation speed of the water-cooled copper roller 5 to 2000 rpm / min, rotate counterclockwise; pour the metal melt into the tundish crucible 2, the melt flows out from the diversion nozzle 3, the flow rate is 15 g / s, the melt is centrifugally atomized into tiny droplets, and then the water-cooled copper roller 5 The inner wall is impacted and deformed into flake powder. The flaky powder has a round and bright appearance; the particle size of the powder is 15-100 μm; the aspect ratio is concentrated between 100-200, and the oxygen content is 800 ppm.

Embodiment 3

[0031] Get 50 kilograms of metal iron and put it into the melting crucible 1; keep the normal pressure in the atomization chamber 6. Put metal iron into the melting crucible 1, use medium frequency induction heating, melt and overheat and keep warm to 1800°C, start and adjust the rotation speed of the turntable atomizer 4 to 50,000 rpm, rotate clockwise, and the rotation speed of the water-cooled stainless steel roller 5 to 20,000 rpm / min, rotate counterclockwise; pour the metal melt into the tundish crucible 2, the melt flows out from the nozzle 3, the flow rate is 100 g / s, the melt is centrifugally atomized into tiny droplets, and the water-cooled stainless steel roller 5 The inner wall is impacted and deformed into flake powder. The flaky powder has a round and bright appearance; the particle size of the powder is 1-75 μm; and the oxygen content is 2000 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com