Method for continuous and efficient production of edible fungus culture medium by utilizing sugar cane by-products

A technology of edible fungi and culture medium, applied in the field of waste resource utilization, can solve the problems of high viscosity of molasses, high operating costs, easy corruption and pollution, etc., achieve high biotransformation rate, save additives, and accelerate mushrooming speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the method for continuously and efficiently producing edible fungus medium by-product of sugar cane sugar production

[0051] Edible fungus culture medium produced continuously and efficiently, with a pH of 7.5 and a water content of 63%, consists of the following components by weight: 82 parts of bagasse, 10 parts of filter mud, 12 parts of water for washing filter cloth in sugar factories, and 4 parts of molasses , 6 parts of brewer's grains, 2 parts of bran.

[0052] According to the above-mentioned formula quantity, the method for continuously and efficiently producing edible fungus culture medium comprises the steps:

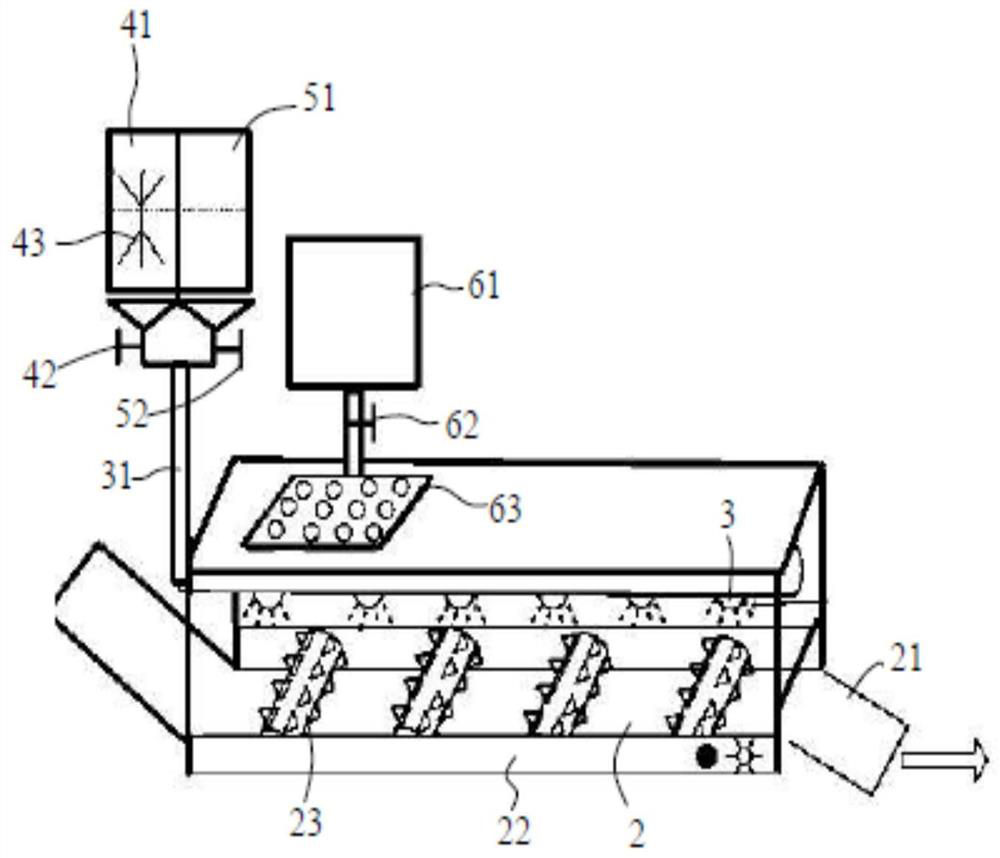

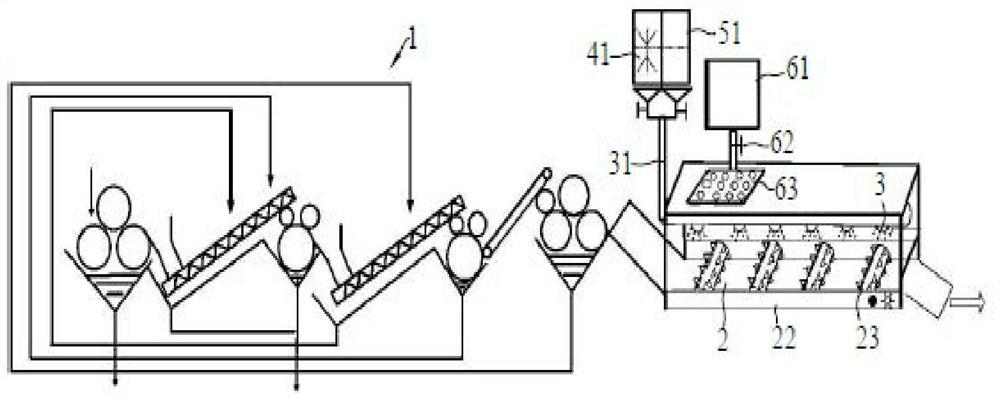

[0053] (1) On the bagasse output device of the sugarcane pressing production line, add a special-purpose continuous production edible fungus medium batching device, and the batching device is provided with a transmission device, an alkali adding mechanism, a water replenishing mechanism and a nitrogen adding mechanism;

[0054] (2) The...

Embodiment 2

[0060] Embodiment 2, the method for continuously and efficiently producing edible fungus culture medium by-product of sugarcane sugar production

[0061] Edible fungus culture medium produced continuously and efficiently, with a pH of 7.5 and a water content of 65%, consists of the following components by weight: 90 parts of bagasse, 10 parts of filter mud, 18 parts of water for washing filter cloth in sugar factories, and 5 parts of molasses .

[0062] According to the above-mentioned formula quantity, the method for continuously and efficiently producing edible fungus culture medium comprises the steps:

[0063] (1) On the bagasse output device of the sugarcane pressing production line, add a special-purpose continuous production edible fungus medium batching device, and the batching device is provided with a transmission device, an alkali adding mechanism, a water replenishing mechanism and a nitrogen adding mechanism;

[0064] (2) The alkali-adding mechanism is provided w...

Embodiment 3

[0069] Embodiment 3, the method that utilizes sugarcane sugar by-product to continuously and efficiently produce edible fungus culture medium

[0070] Edible fungus culture medium produced continuously and efficiently, with a pH of 7.0 and a water content of 60%, consists of the following components by weight: 82 parts of bagasse, 5 parts of filter mud, 12 parts of water for washing filter cloth in sugar factories, and 3 parts of molasses , 6 parts of brewer's grains, 2 parts of bran.

[0071] According to the above-mentioned formula quantity, the method for continuously and efficiently producing edible fungus culture medium comprises the steps:

[0072] (1) On the bagasse output device of the sugarcane pressing production line, add a special-purpose continuous production edible fungus medium batching device, and the batching device is provided with a transmission device, an alkali adding mechanism, a water replenishing mechanism and a nitrogen adding mechanism;

[0073] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com