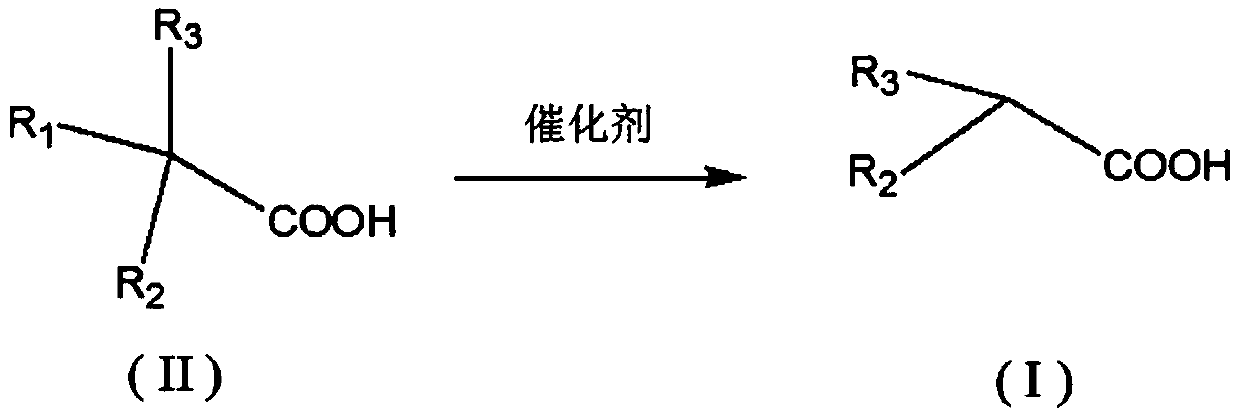

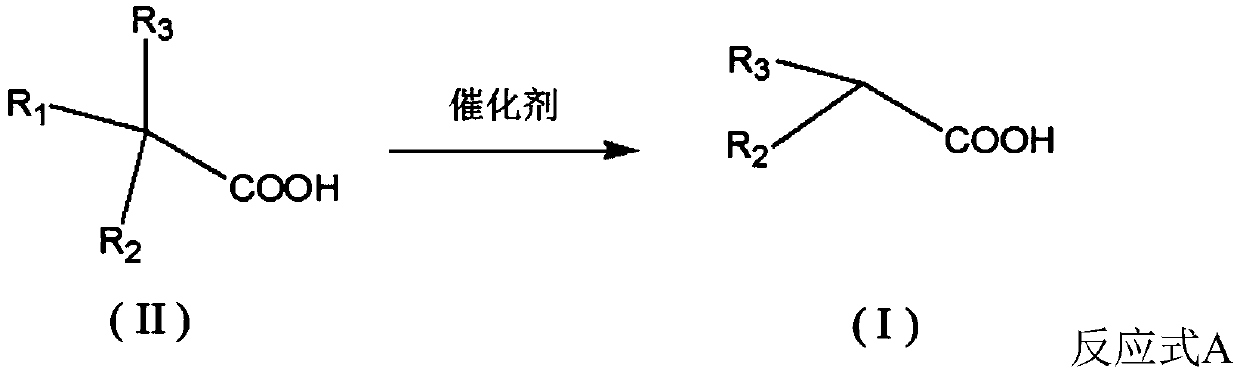

A kind of preparation method of carboxylic acid

A carboxylic acid and step method technology, applied in the field of carboxylic acid preparation, can solve the problems of large investment and complex composition of reaction solution, and achieve the effects of high selectivity, easy control and operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Activated alumina powder (purchased from Aluminum Corporation of China Shandong Branch) was placed in a muffle furnace and calcined at 500°C for 3 hours under static or flowing air with a heating rate of 5°C / min to obtain calcined alumina powder . Weigh 0.8-1.2 g of calcined activated alumina, press into tablets, grind, and take 40-60 mesh particles as the catalyst.

[0029] The prepared Al 2 o 3 The catalyst is installed in the middle of a tubular reactor with a diameter of 8 mm and a length of 45 cm, and the upper and lower parts of the catalyst are filled with 40-60 mesh quartz sand. Then place the tubular reactor filled with catalyst in the heating furnace, open the carrier gas (N 2 ) and feed, the feed flow rate is 20ml / min, open the heating device, make the temperature reach 300°C in the mode of temperature program (3-5°C / min), constant temperature, feed 10wt% lactic acid aqueous solution, feed flow rate Be 0.5ml / min, begin to collect product and carry out pro...

Embodiment 2

[0031] The activated silica powder was placed in a muffle furnace and calcined at 500° C. for 3 hours under static or flowing air with a heating rate of 5° C. / min to obtain calcined silica powder. Weigh 0.8-1.2 g of the calcined silicon dioxide, press into tablets, grind, and take 40-60 mesh particles as the catalyst.

[0032] The prepared silicon dioxide catalyst was placed in the middle of a tubular reactor with a diameter of 8 mm and a length of 45 cm, and the upper and lower parts of the catalyst were filled with 40-60 mesh quartz sand. Then place the tubular reactor filled with catalyst in the heating furnace, open the carrier gas (N 2) and pass in, the flow rate is 20ml / min, the heating device is turned on, and the temperature reaches 300°C in the mode of temperature program (3-5°C / min), at a constant temperature, 10wt% lactic acid aqueous solution is passed in, and the flow rate is It was 0.5ml / min, and the product was collected and analyzed after 3 hours of reaction, ...

Embodiment 3

[0034] The activated alumina powder was placed in a muffle furnace and calcined at 500° C. for 3 hours under static or flowing air with a heating rate of 5° C. / min to obtain calcined alumina powder.

[0035] Weigh 0.2g of barium sulfate in a beaker, add 30ml of deionized water, add 1.0g of calcined alumina powder into the solution, use ultrasonic impregnation method, treat at room temperature for three hours, and then place the obtained solution in microwave Microwave treatment in the processor for 2 hours, after suction filtration / rotary evaporation filtration, the obtained catalyst was dried in a drying oven at 130°C for 4 hours, and then calcined with programmed temperature control at a heating rate of 5-10°C / min, set Set the calcination temperature at 600°C, and calcine at constant temperature for 3 hours to obtain 20wt% BaSO 4 / Al 2 o 3 Supported catalyst, where BaSO 4 Equivalent to carrier Al 2 o 3 The loading amount is 20wt%.

[0036] The obtained 20wt% BaSO 4 / A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com