Manufacturing method of optical film, polarizing plate, and image display device

A manufacturing method and technology for optical films, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as reduced manufacturing efficiency, defects in surface shape or optical characteristics, damage to mechanical strength and optical characteristics of optical films, etc. The effect of manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The following components were mixed to prepare an ultraviolet curable coating liquid.

[0102] Ultraviolet curable resin: 60 parts by weight of pentaerythritol triacrylate and 40 parts by weight of polyfunctional urethane acrylate (reaction product of hexamethylene diisocyanate and pentaerythritol triacrylate)

[0103] · "Lucirin TPO" (manufactured by BASF Corporation, chemical name: 2,4,6-trimethylbenzoyldiphenylphosphine oxide) 5 parts by weight

[0104] • Diluting solvent: 100 parts by weight of ethyl acetate.

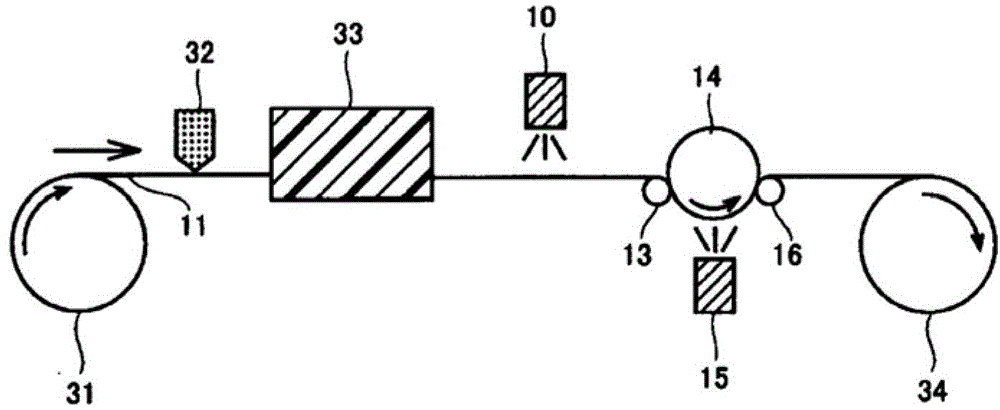

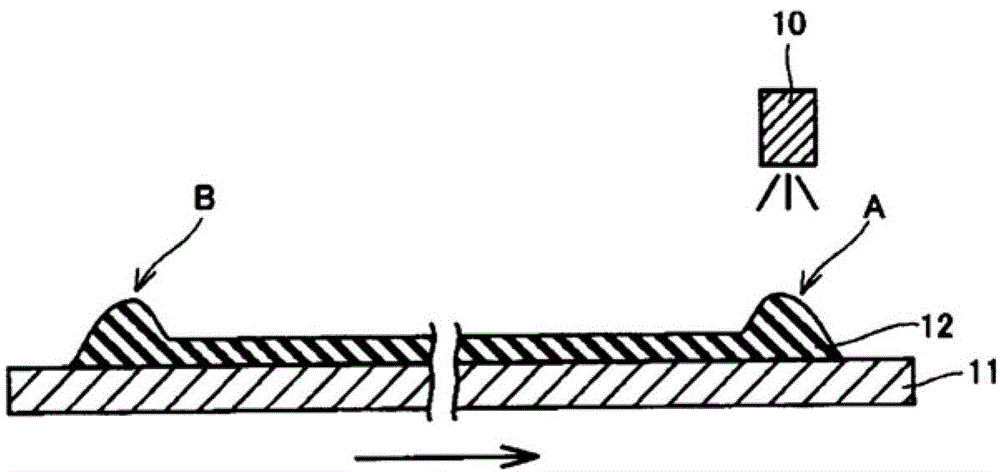

[0105] Apply the above-mentioned coating solution to a triacetyl cellulose (TAC) film (base film) with a thickness of 80 μm by gravure coating to form a coating layer, and obtain a laminate of the base film and the coating layer [coating process] ]. After drying the obtained laminated body using a drying oven, an ultraviolet irradiation device having a comb-shaped filter having a plurality of comb-shaped teeth whose width gradually narrows in the direction ...

Embodiment 2~5

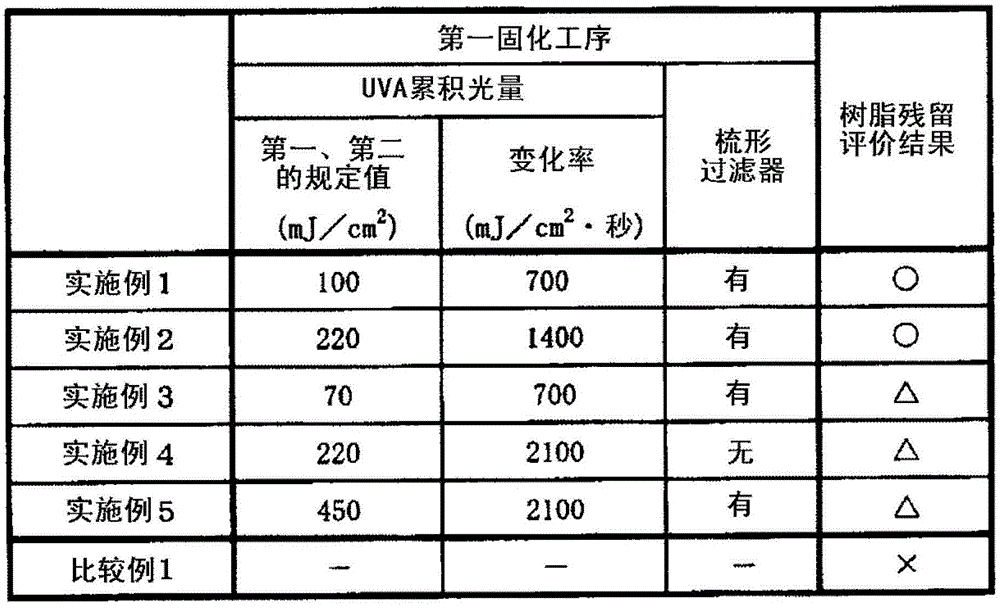

[0108] As shown in Table 1, the first predetermined value and the second predetermined value, and the rate of change of the accumulated light amount per second of UVA of ultraviolet rays were changed, and the same operation as in Example 1 was performed to produce optical film. In addition, in Example 4, no comb filter was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com