A kind of liquid oil rich in furan substances and its preparation method

A liquid oil and furan technology, applied in the field of biomass utilization, can solve problems such as increasing operating costs, increasing operation complexity, and equipment corrosion, and achieve the effects of improving reaction efficiency and avoiding environmental pollution and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The embodiment of the present invention describes the method of using biomass to prepare liquid oil rich in furan substances, which specifically includes the following steps:

[0051] S1 crush and sieve the corncobs to be less than 120 mesh, pickle with hydrochloric acid with a mass fraction of 5%, the mass ratio of hydrochloric acid solution to biomass is 20:1, and put the biomass samples after pickling at 105°C after washing After drying in an oven for 24 hours, the pyrolysis raw material was obtained;

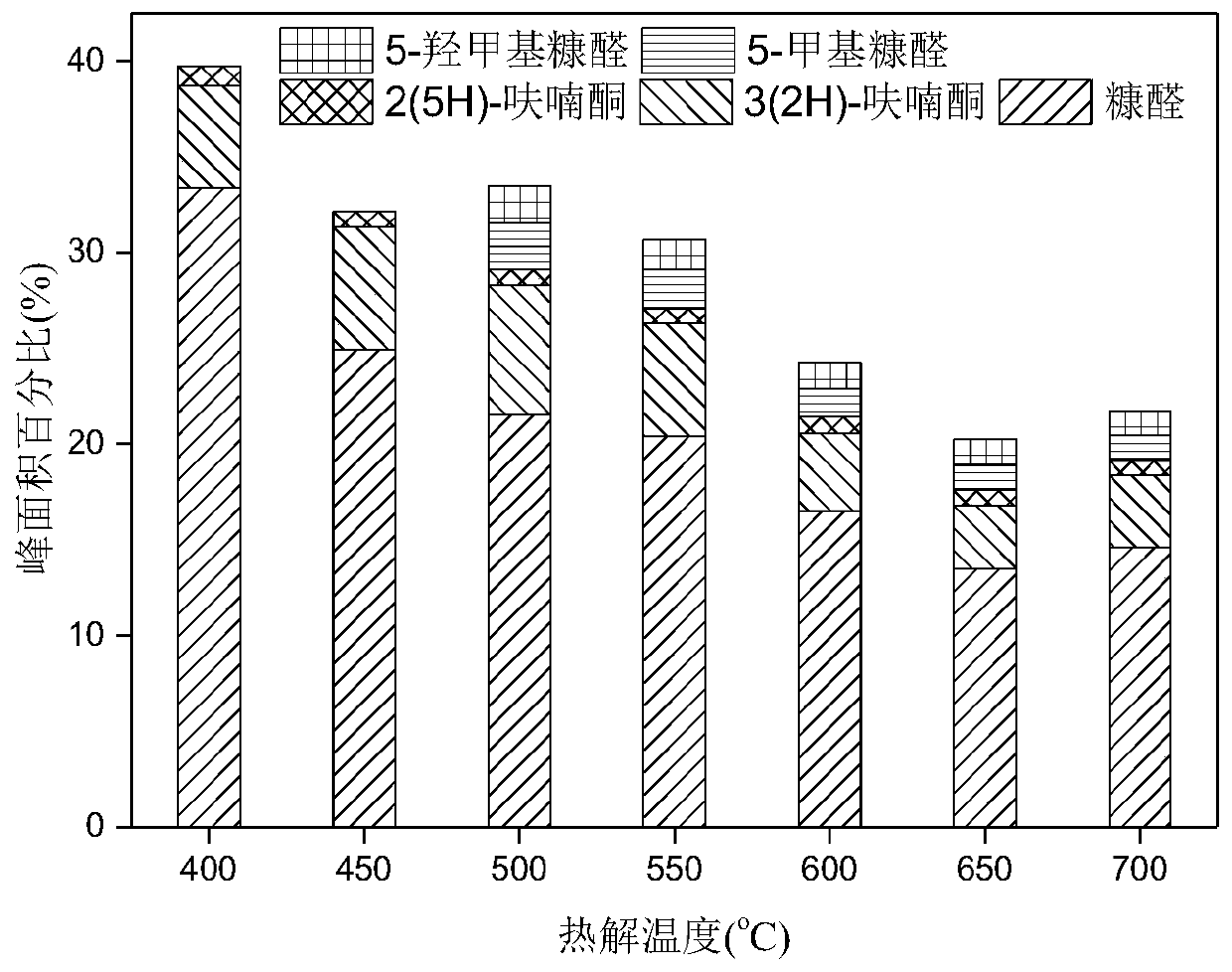

[0052] S2 uses a fast cracking reactor for catalytic pyrolysis. After the reactor is heated to a specified temperature of 550°C, the pyrolysis raw material and Zr-Cu / SAPO-18 molecular sieve catalyst are catalytically pyrolyzed. The reaction time is 15s. Zr-Cu / SAPO The mass ratio of -18 molecular sieve catalyst to pyrolysis raw material is 2:1;

[0053] S3 pyrolysis volatiles are brought into the condenser by the mixed gas, and cooled by the ice-water mixture to becom...

Embodiment 2

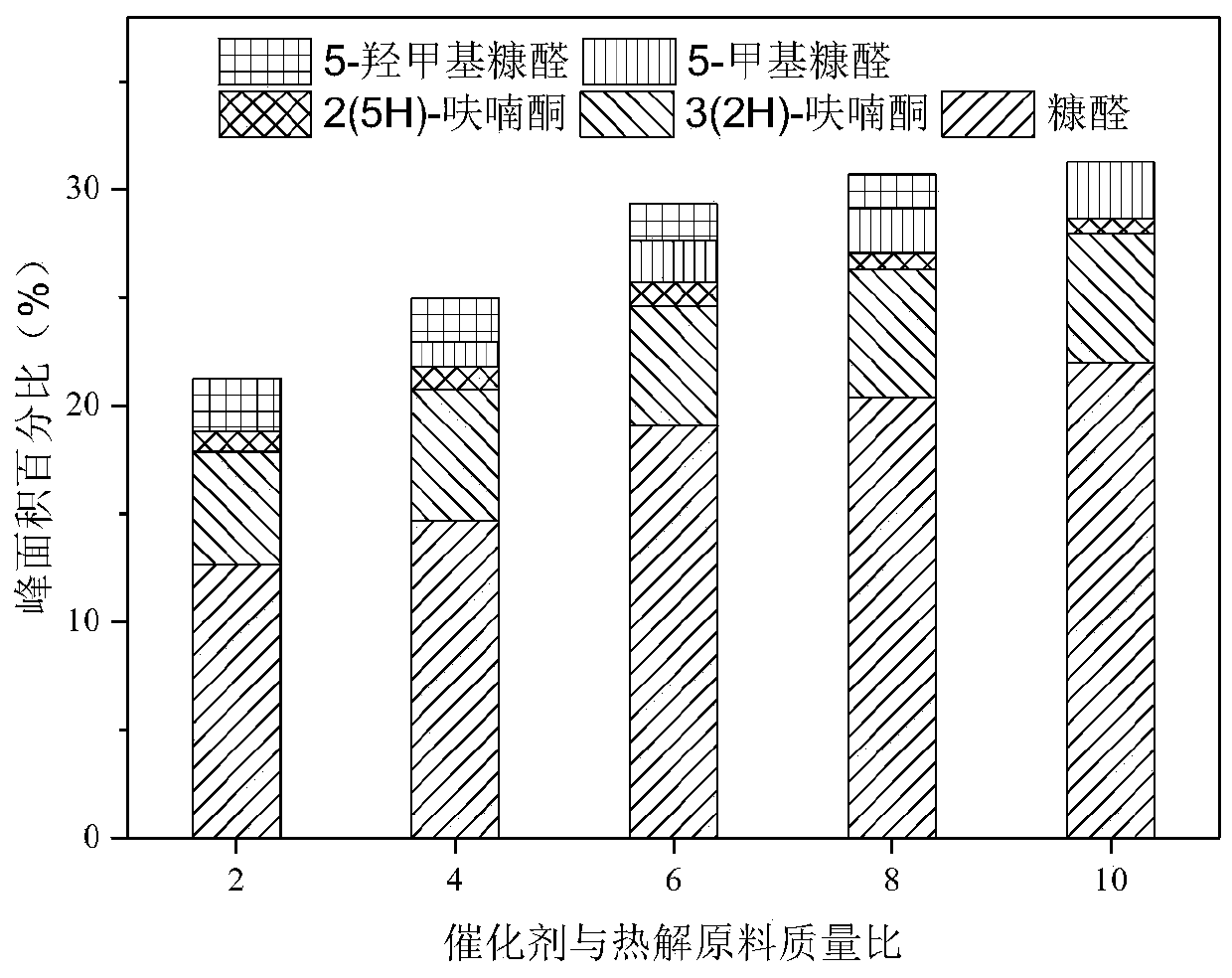

[0055] This example is the same as Example 1, except that the mass ratio of the Zr-Cu / SAPO-18 molecular sieve catalyst to the pyrolysis raw material is 4:1.

Embodiment 3

[0057] This example is the same as Example 1, except that the mass ratio of the Zr-Cu / SAPO-18 molecular sieve catalyst to the pyrolysis raw material is 6:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com