Droplet target control system guided by laser beam

A technology for controlling a system and a laser beam, applied in the field of plasma light sources, can solve the problem of high difficulty in realizing a drop target system, and achieve the effects of long-term accurate and stable spatial coincidence, slowing down the falling speed, and realizing time synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

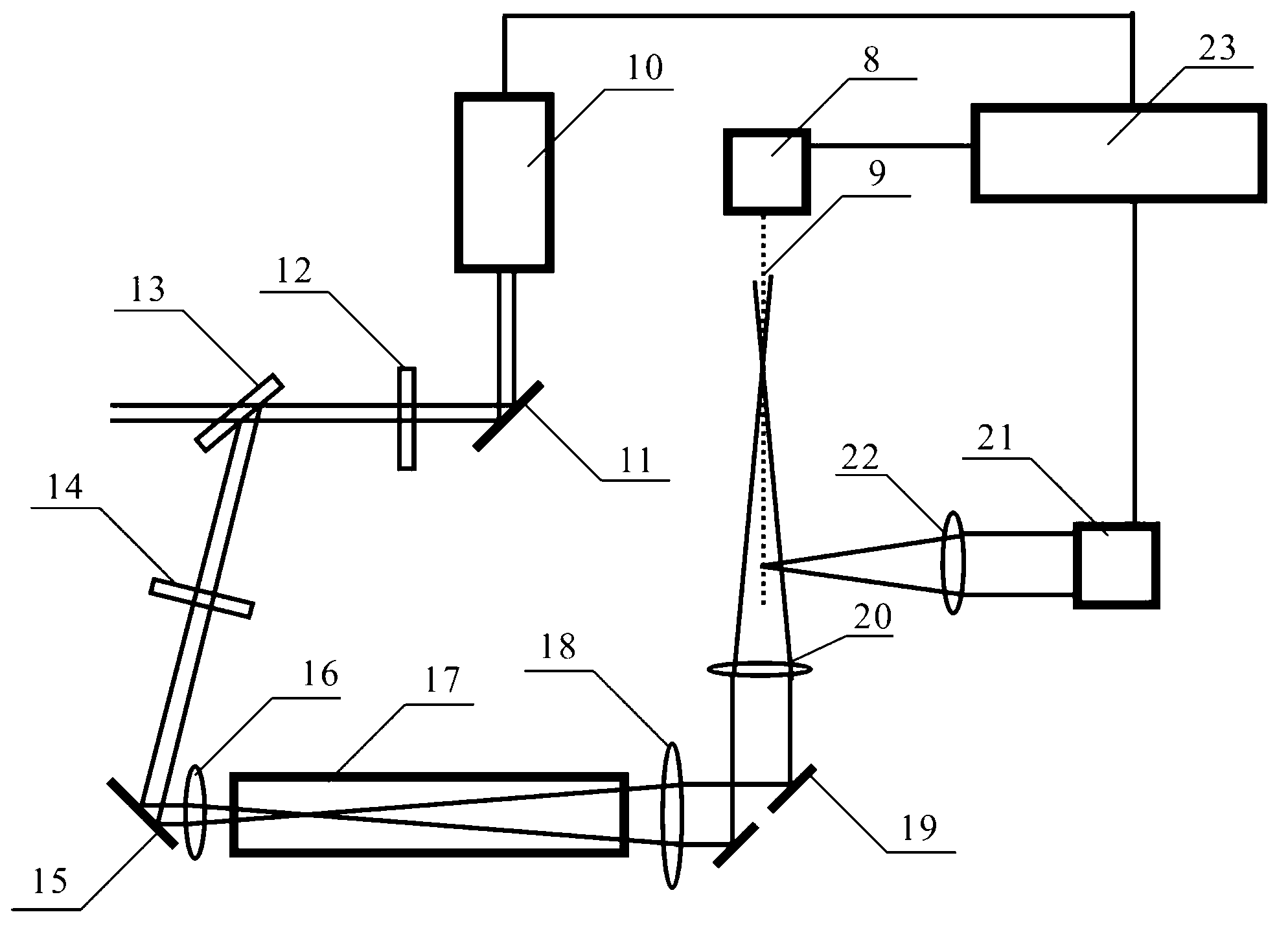

[0017] Such as figure 2 Shown is a schematic structural view of the laser beam guided droplet target control system of the present invention. As can be seen from the figure, the droplet target control system guided by the laser beam of the present invention includes a droplet nozzle 8, a high-power pump laser 21, a third focusing lens 22 and a delay pulse generator 23, and also includes a laser light source 10, a first Mirror 11, half-wave plate 12, Brewster’s angle polarizer 13, quarter-wave plate 14, second mirror 15, first focusing lens 16, vacuum tube 17, second focusing lens 18, annular plane reflector Mirror 19 and annular focusing lens 20, the positional relationship of the above-mentioned components is as follows: along the laser direction of the laser light source 10 output is the first reflector 11, half-wave plate 12, Brewster angle polarizer 13, four One-half wave plate 14, the second reflection mirror 15, the first focus lens 16, the vacuum tube 17, the second f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com