Flexibly-driven active steering type pipeline robot

A pipeline robot and active steering technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of poor pipeline adaptability, limited output power, and reduced operating efficiency, and achieve good adaptability in the pipe and ensure traction output. , the effect of improving the output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed implementation of the present invention will be described below in conjunction with the accompanying drawings and specific examples.

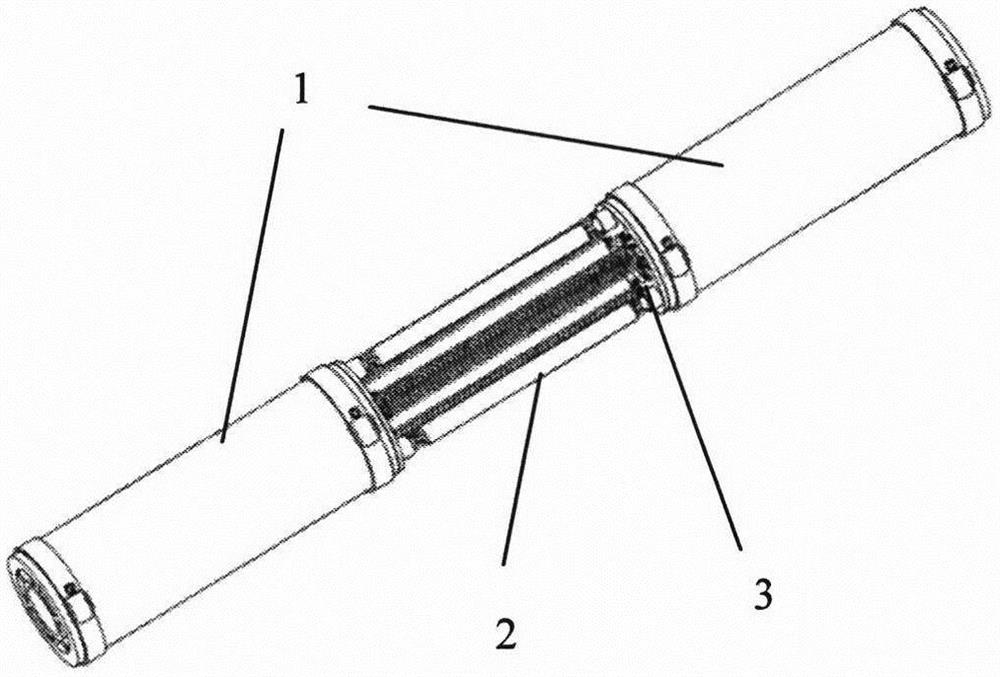

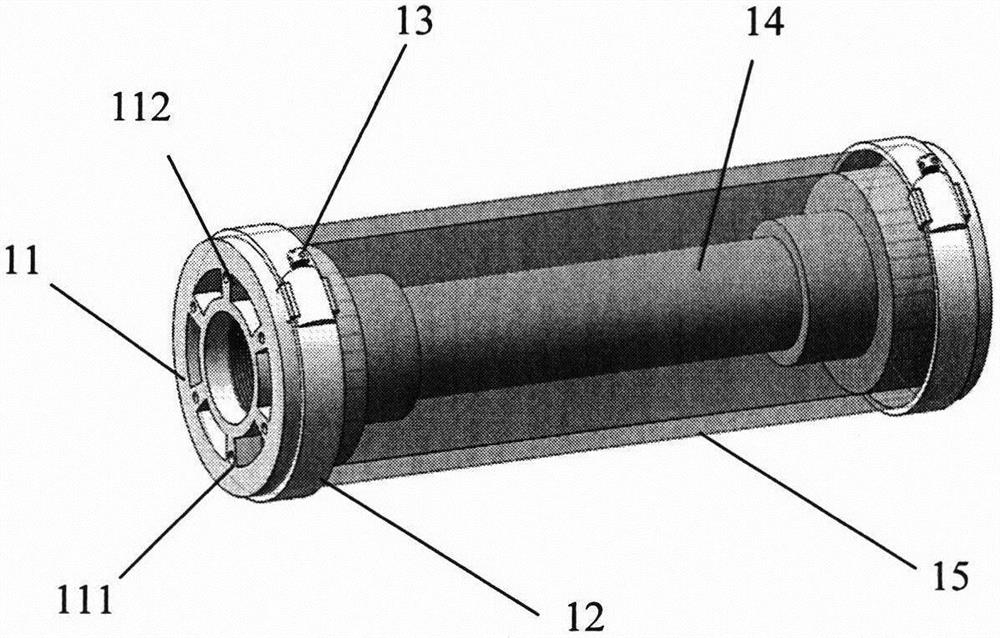

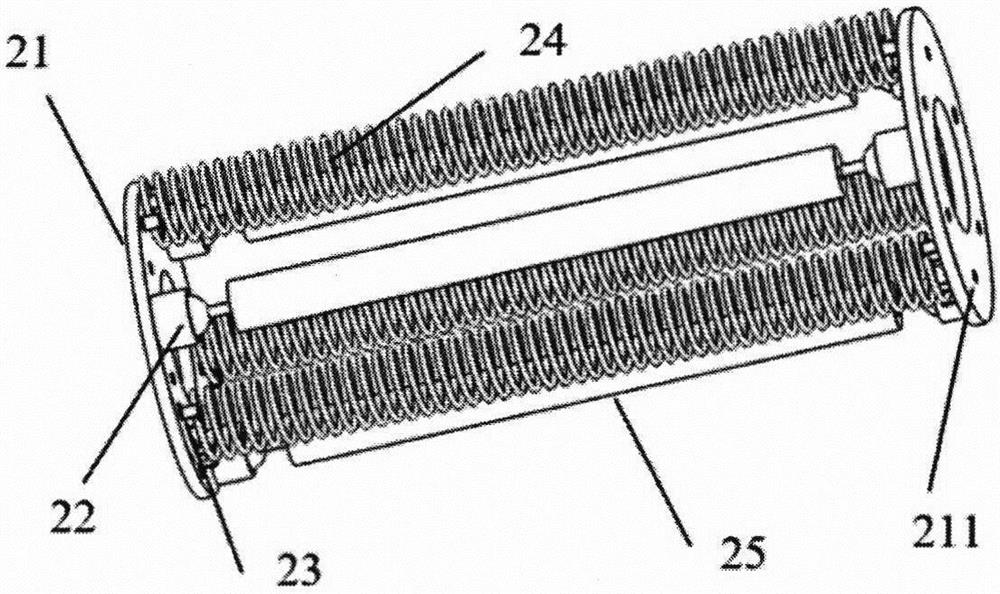

[0024] Such as Figure 1-3 As shown, the flexibly driven active steering pipeline robot in this example includes a flexible telescopic module 2 and two flexible support modules 1 arranged along the lengthwise ends of the flexible telescopic module 2 . The flexible support module 1 and the flexible telescopic module 2 are fixedly connected by connecting screws. The flexible support module 1 completes the support and detachment of the inner wall of the pipe through the expansion and contraction of the flexible support body 15. In cooperation with it, the flexible telescopic module 2 completes the movement of the pipeline robot through the contraction and reset of the flexible telescopic body 25 and the return spring 24.

[0025] In this example, the flexible support module 1 includes two flexible support end caps 11 of annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com