Device for realizing 3D metal printing by virtue of supporting structure

A technology of support structure and 3D printing, applied in the direction of additive processing, etc., can solve the problems of inability to realize 3D rapid prototyping of complex parts with high melting point metal, and achieve the effects of guaranteed molding quality, strong operability, and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

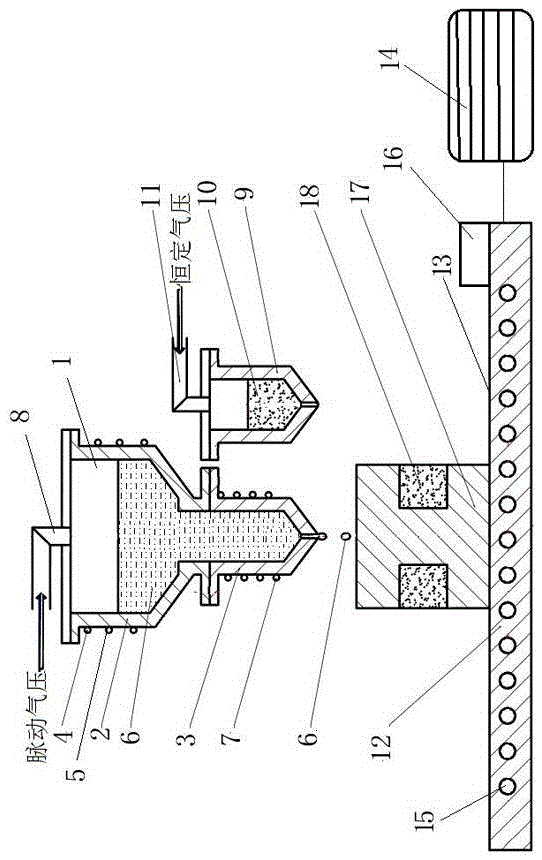

[0017] Such as figure 1 As shown, a metal 3D printing and support structure device includes a melting device, a support structure arranged at the side end of the melting device, and a moving translation device. The melting device includes a sealed glove box 1, a graphite crucible 2 and a metal melting device. Liquid nozzle 3, the graphite crucible 2 is installed on the top of the sealed glove box 1, the molten metal nozzle 3 is arranged at the bottom of the graphite crucible 2, the molten metal nozzle 3 is connected to the graphite crucible 2, and the graphite crucible 2 The periphery is wrapped with electromagnetic induction heating copper pipe 4 and cooling water pipe 5. Metal melt 6 is arranged in the graphite crucible 2, and the metal melt 6 is formed by electromagnetic induction heating of metal raw materials. The inside of the graphite crucible 2 is In a confined space, a heating resistance wire 7 is wound around the metal solution nozzle 3, and the heating resistance wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com