Metal ion source and vacuum coating system

A metal ion source and cooling system technology, applied in the direction of ion implantation plating, vacuum evaporation plating, metal material coating technology, etc., can solve the problem of unstable discharge, large difference in ionization rate of deposited particles, low deposition rate, etc. problem, to achieve the effect of increasing the density of the extracted beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

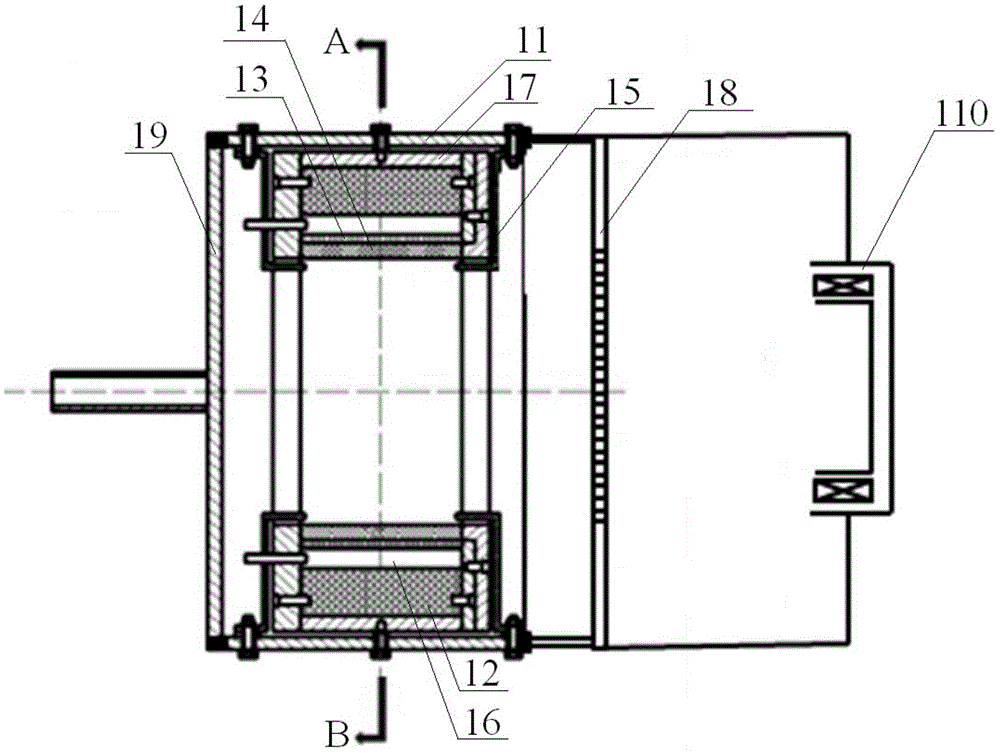

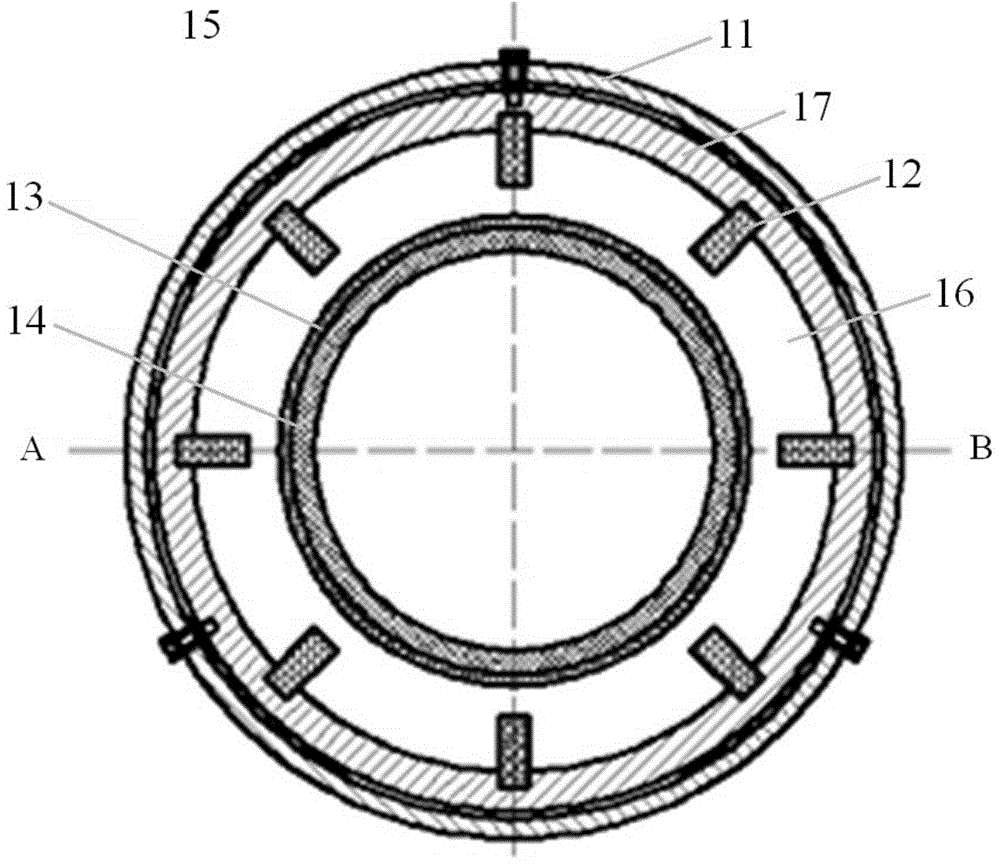

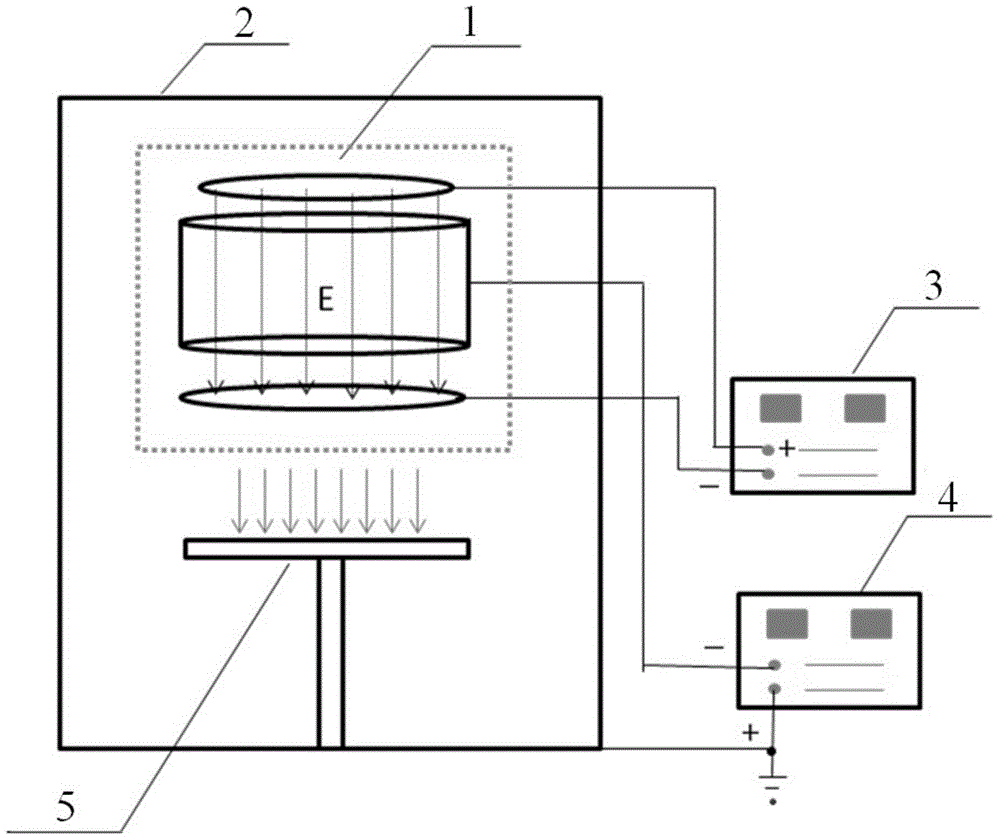

[0029] The source of metal ions in this example, such as figure 1 As shown, it includes a casing 11, a magnetic element 12, a copper sleeve 13, a magnetron target 14, an arc extinguishing cover 15, a cooling system 16, a magnetic steel 17, a mesh-shaped extraction grid 18, and a positive electrode 19 for an extraction electric field; the casing 11 is Hollow cylindrical shape; magnetic steel 17, cooling system 16, copper sleeve 13 and magnetron target 14 are sequentially stacked in the shell 11, and none of them are connected to the shell 11; magnetron target 14 is embedded in the copper sleeve 13 , the magnetic element 12 is evenly inlaid on the magnetic steel 17; the arc extinguishing cover 15 is fixed on both ends of the cylindrical shell, and the magnetic steel 17, the cooling system 16, the copper sleeve 13 and the magnetic The two ends of the control target 14 are wrapped, and there is a gap between the arc extinguishing cover 15 and the magnetic element 12, the copper sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com