An isotope production facility

A technology for producing equipment and isotopes, applied in the field of isotope production equipment, can solve problems such as increased shielding cost, poor beam quality, thermal radiation activation, etc., and achieve the effect of improving production capacity and efficiency and saving equipment manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

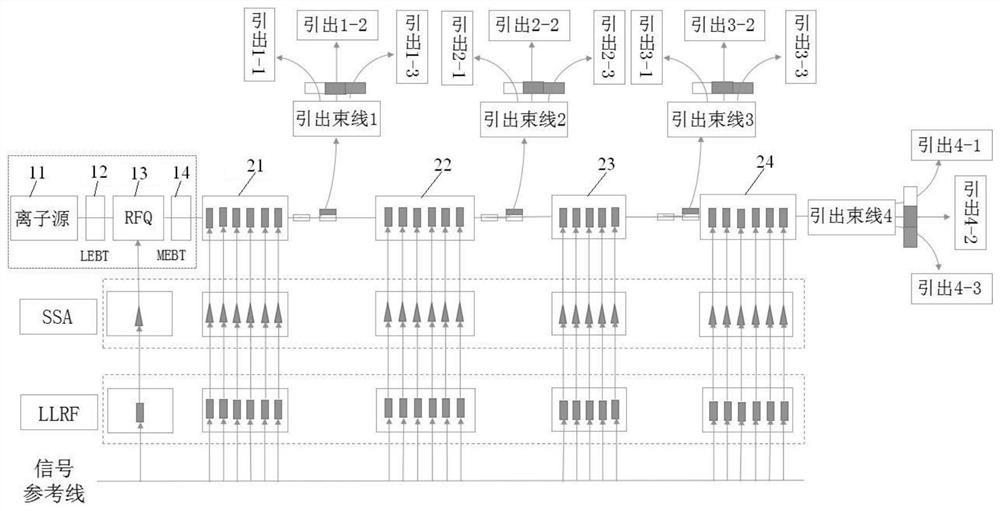

[0045] An embodiment of the present invention provides an isotope production equipment, which specifically includes a linear accelerator and a corresponding target system; refer to figure 1 , the linear accelerator includes a normal-temperature front-end accelerator, N identical accelerating units arranged in series behind it, and an extraction beamline drawn from the output end of the terminal acceleration unit, which is used to output the proton beam used by the target system , the target system is used for isotope generation.

[0046] The room temperature front-end accelerator and each acceleration unit have their own independent RF power source, feed system and low-level control system; the RF power and synchronization phase of each acceleration unit can be continuously adjusted through its low-level control system, thereby realizing The continuous adjustment of the output energy gain finally realizes the continuous adjustment of the output energy on the end-leading beam. ...

Embodiment 2

[0058] Based on the isotope production equipment disclosed in Embodiment 1 above, in Embodiment 2 of the present invention, the linear accelerator with continuously adjustable energy is modularized, and some acceleration units are coupled together to form each acceleration module, that is, N Multiple adjacent acceleration units in the acceleration unit are coupled to form an acceleration module, and the output end of each acceleration module is provided with a corresponding extraction beamline, and these extraction beamlines are used to output the proton beam used by the target system that is matched with it . It can be understood that the energy of a single acceleration module is continuously adjustable mainly because the amplitude and phase of the electric field of the acceleration units it contains are independently adjustable.

[0059] Among them, the extraction of the beam is realized by the beam splitting device, which can be specifically composed of a cutting magnet and...

Embodiment 3

[0065] Based on the isotope production equipment disclosed in the above-mentioned embodiment 1 and embodiment 2 of the present invention, in embodiment 3 of the present invention, ECR ion source and RFQ accelerator are used for the normal temperature front-end accelerator in the linear accelerator, and the acceleration cavity of the acceleration unit is a low-temperature superconducting cavity body, the whole linear accelerator of the present invention can provide tens of mA-level proton beam currents for all extraction beamlines, so even if all extraction beamlines work simultaneously, the beam current with an average current intensity of several mA can also be drawn out. Several secondary extraction beamlines are separated by the beam splitting method, and each target system still has a beam current with an average current intensity of about hundreds of μA, which can still meet the needs of isotope production.

[0066] Based on this, the end of at least one extraction beamlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com