Experiment device and method of wall collision of high-temperature molten metal droplets in negative pressure environment

A metal droplet, high-temperature melting technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to control the impact speed of metal droplets, unable to be used for high-temperature molten metal droplets, plate deformation, etc. Save experimental costs, achieve quantitative measurement, and prevent deformation and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

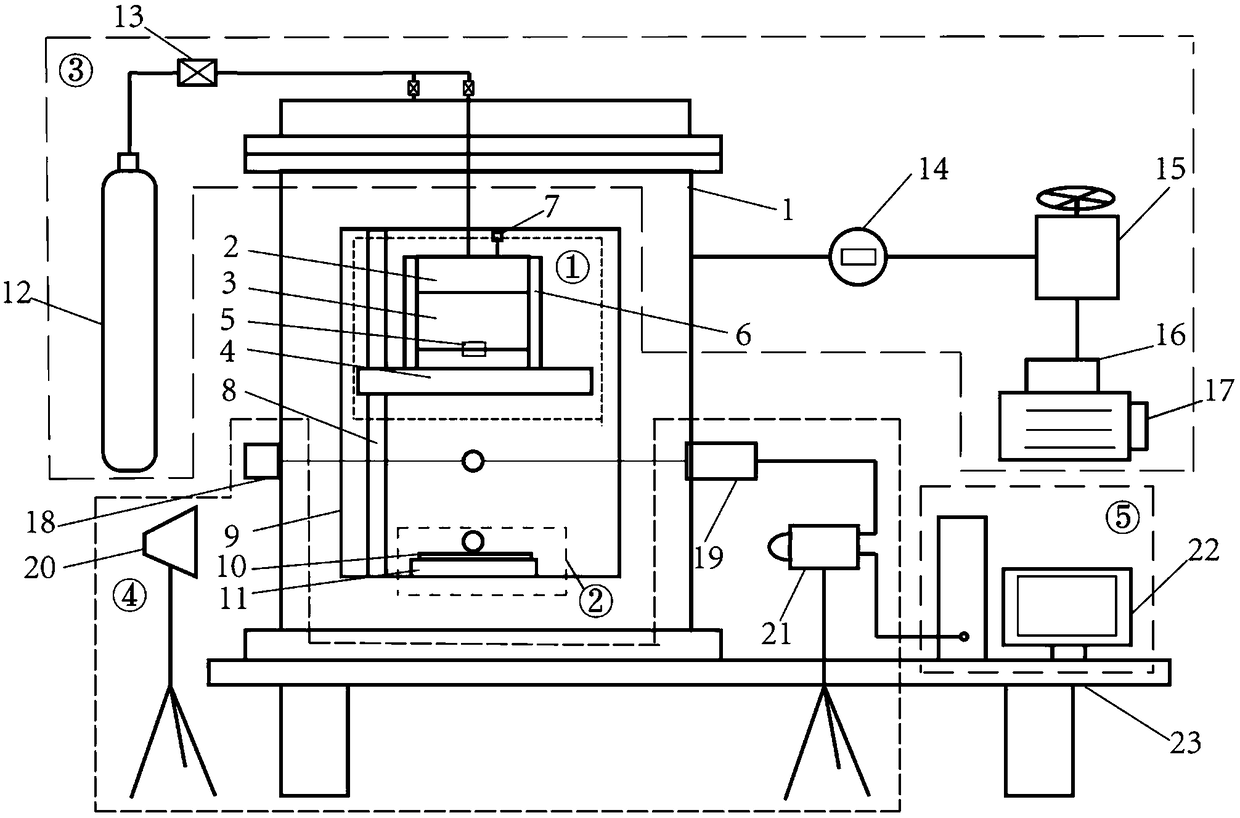

[0054] The present invention is a high-temperature molten metal droplet collision visualization experiment device in a negative pressure environment, which includes a metal droplet generation system, a temperature-controllable wall surface system, an environmental pressure adjustment system, an automatic trigger high-speed photography system, and an image processing system. The five systems Fixedly installed on the air-floating shock-absorbing platform;

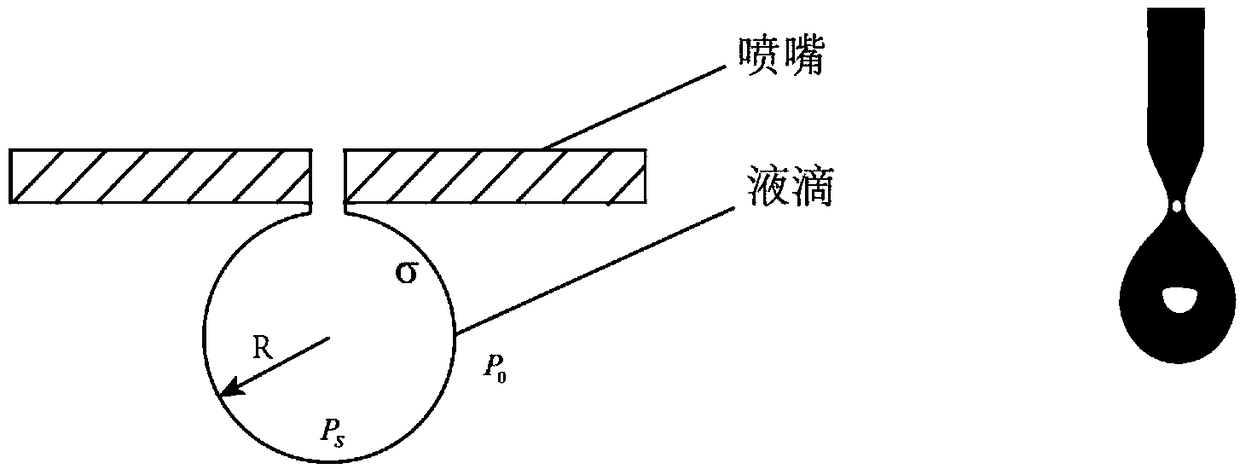

[0055] 1) The metal droplet generating system includes a metal melting furnace, a brass nozzle 5, a ceramic electric heater 6, a nitrogen cylinder 12, an air intake pipeline, a solenoid valve 13, and a pressure transmitter 7; the ceramic electric heater 6 is surrounded by the The outer side of the above-mentioned metal melting furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com