Coated hollow glass with gradual change for building curtain wall and use method of coated hollow glass with gradual change for building curtain wall

A glass and hollow technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of increased stress in hollow glass, easy defects in glass gradient color printing, deformation of glass edges, etc., to prevent deformation and breakage, and use The method is practical and prevents the effect of blurring blemishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

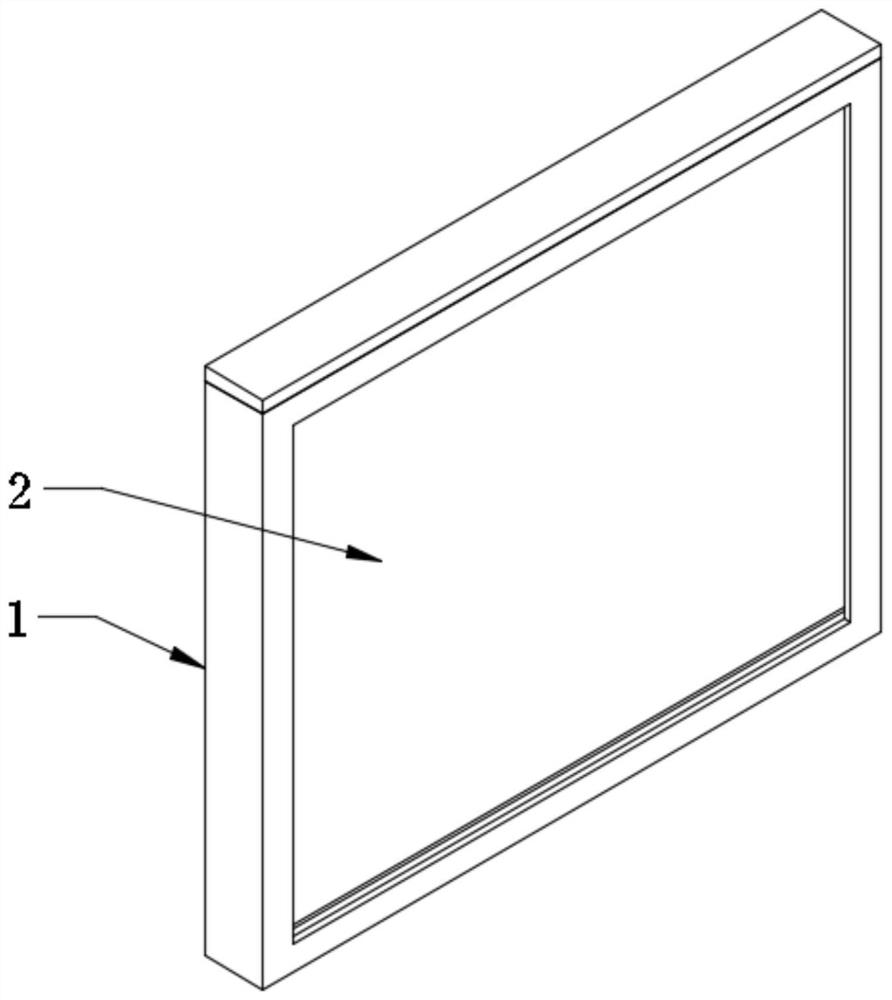

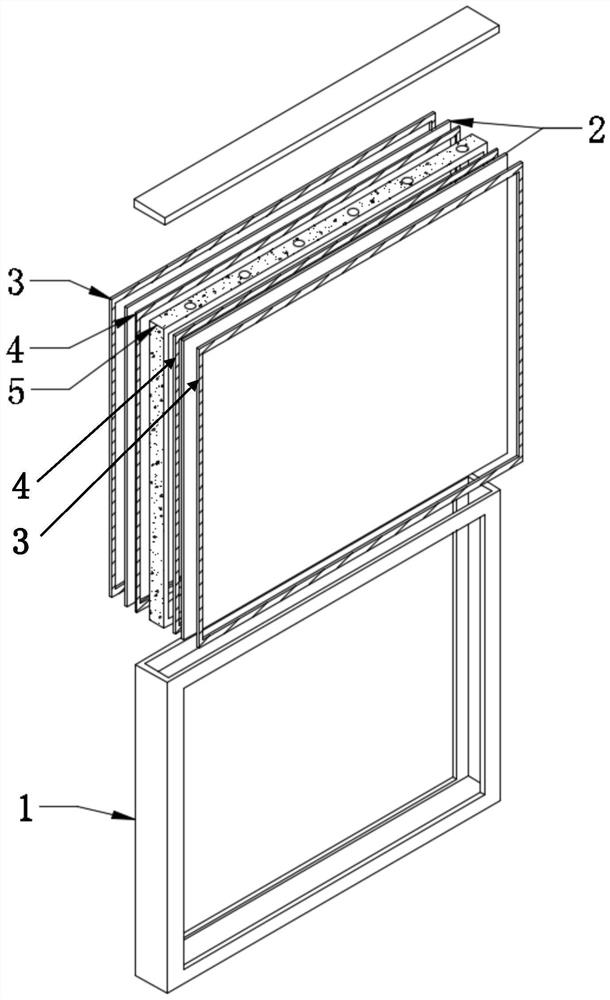

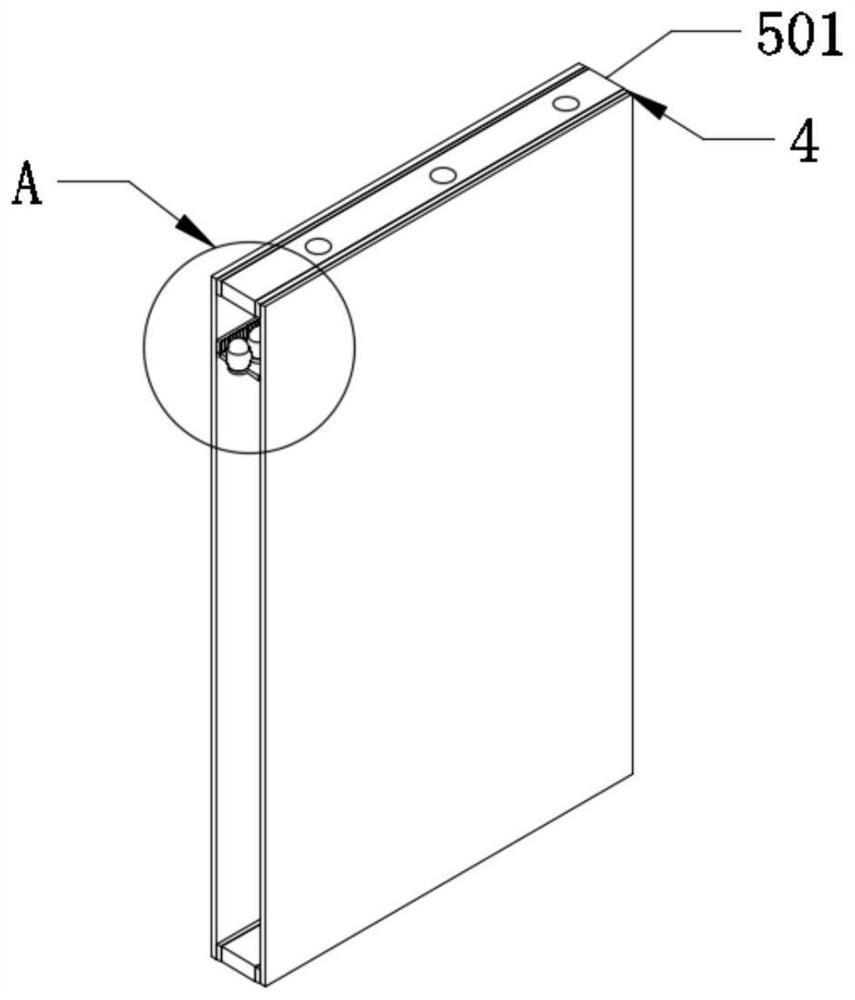

[0030] refer to Figure 1-Figure 5 As shown in the figure, a coated gradient insulating glass for building curtain wall includes a frame 1, and a gradient mechanism 2 is arranged inside the frame 1, and the gradient mechanism 2 is used to reduce the defects of glass gradient. A decompression mechanism 5 is provided, and the decompression mechanism 5 is used for pressure buffering inside the insulating glass;

[0031] The gradient mechanism 2 includes a glass body 201 , a concave point 202 , a heat shield 203 , an anti-fog film layer 204 , a gradient dot layer 205 , an ink layer 206 and an explosion-proof film 207 , and the concave point 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com