Automatic head guiding device of extrusion assembly line for manufacturing tires

An assembly line and tire technology, applied in tires, applications, household appliances, etc., can solve the problems of high labor cost, slow traction speed, low operation efficiency, etc., and achieve the effect of simple structure, prevention of stress deformation and breakage, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

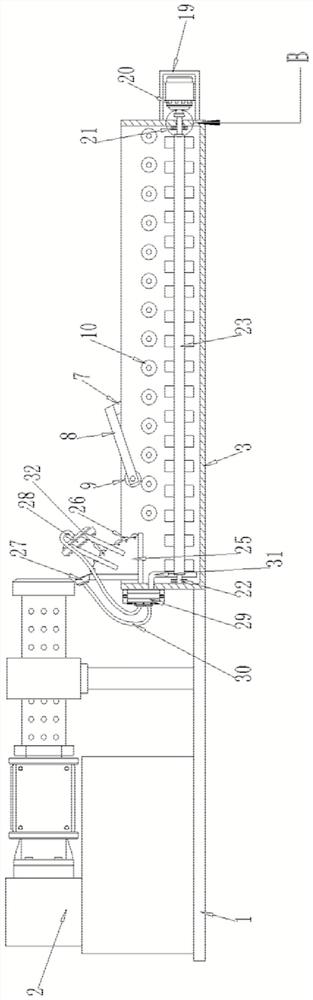

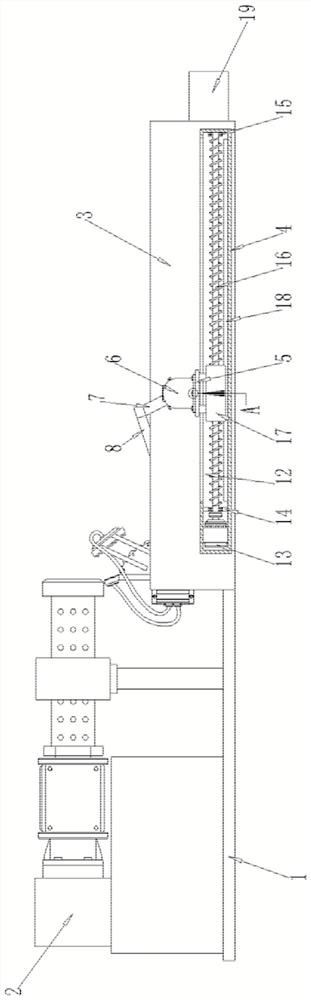

[0027] Example: see Figure 1-5 , the main components of this case are: equipment installation table 1 and tire extruder body 2; tire extruder body 2 is installed on the upper wall surface of equipment installation table 1, and a cooling water tank 3 is installed on the right side of tire extruder body 2. The cooling water tank A movable conveying lead structure is installed on 3, and a reinforced cooling structure is installed on the cooling water tank 3;

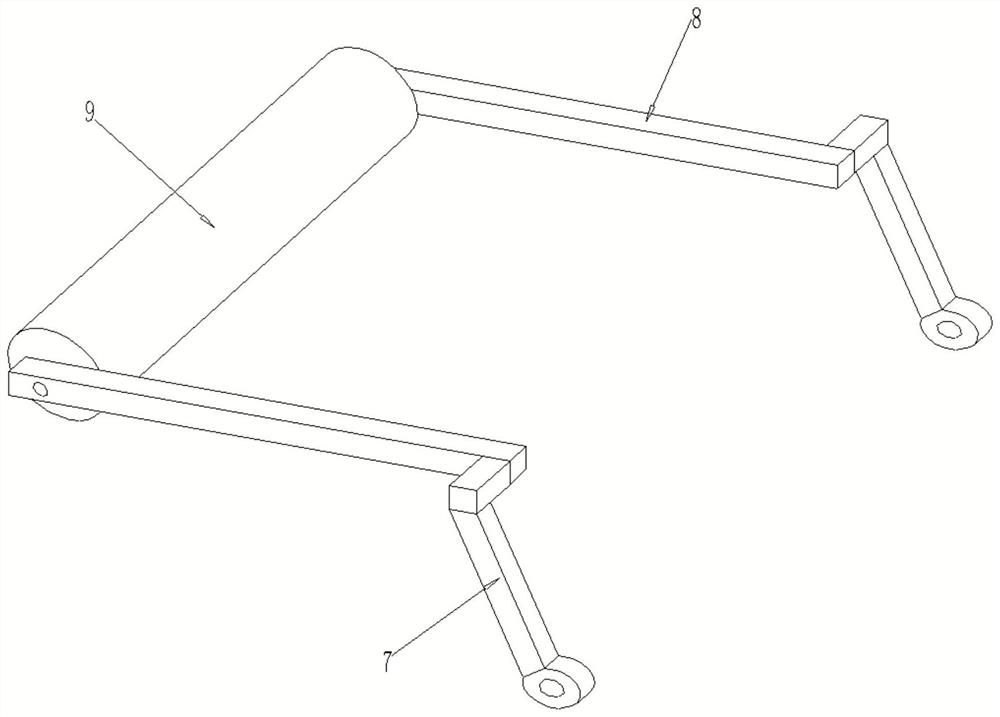

[0028] The mobile conveying leader structure includes: a pair of moving drive boxes 4, a pair of moving drive assemblies, a pair of moving frames 5, a pair of rotary drivers 6, a pair of rotating rods 7, a pair of connecting rods 8 and a leader roller shaft 9;

[0029] A pair of moving drive boxes 4 are installed on the front and rear walls of the cooling water tank 3, a pair of moving drive assemblies are installed inside the pair of moving drive boxes 4, a pair of moving racks 5 are installed on the output ends of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com