High impact inertia micro-fluid power connection switch and manufacturing method thereof

A manufacturing method and microfluidic technology, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of closure, unfavorable fuze safety, etc., and achieve the effect of large contact area, simple structure, and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

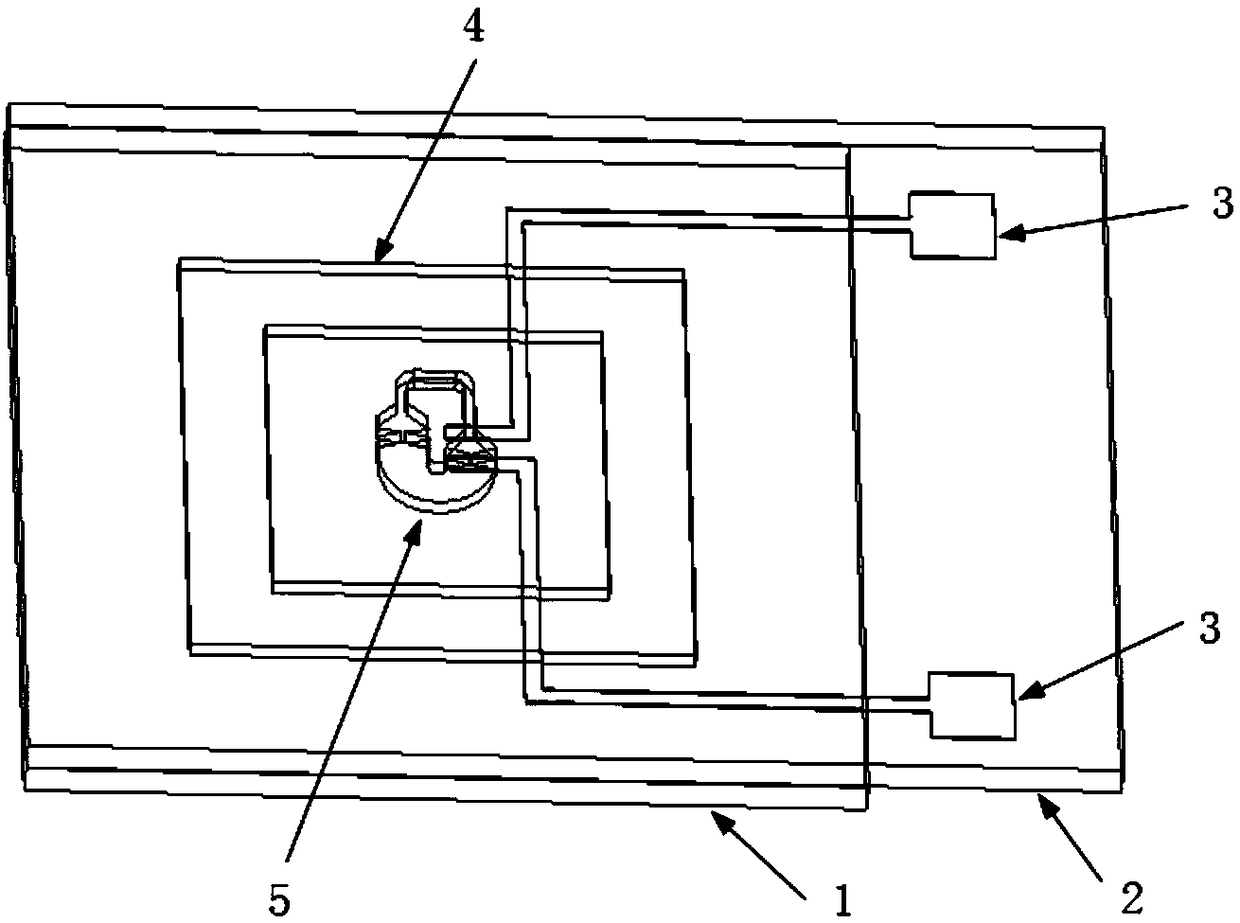

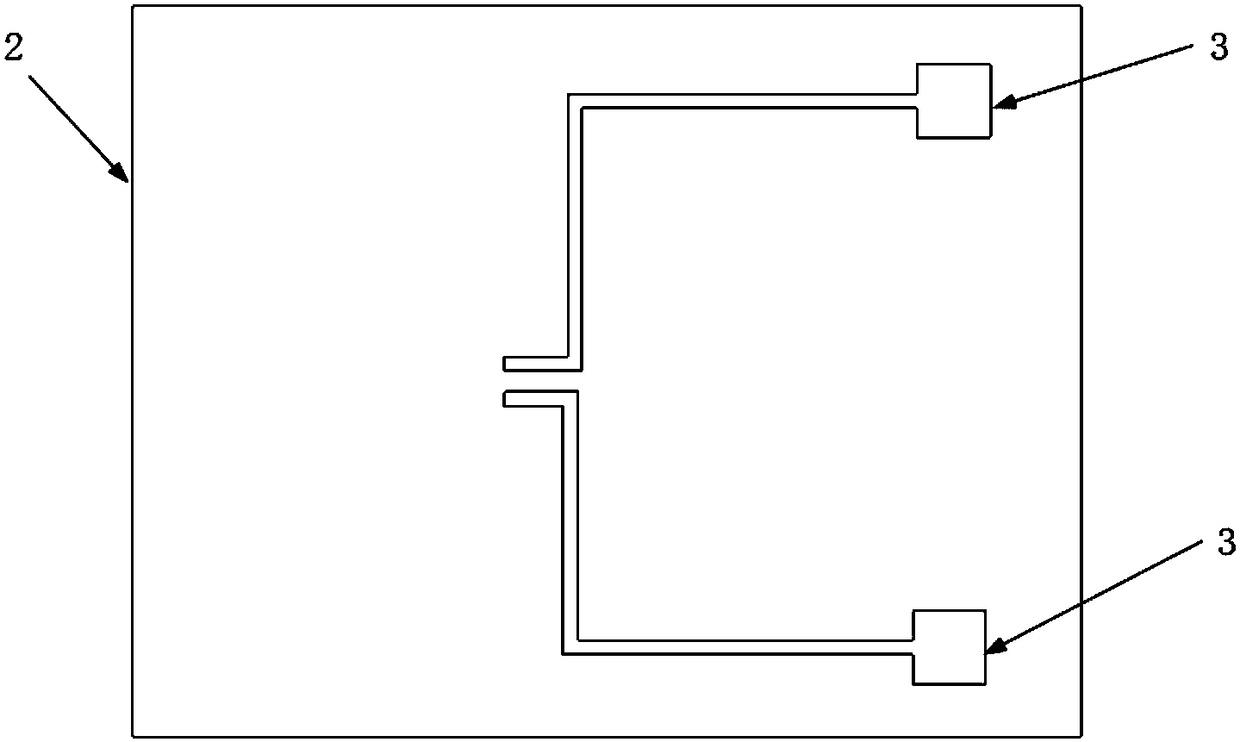

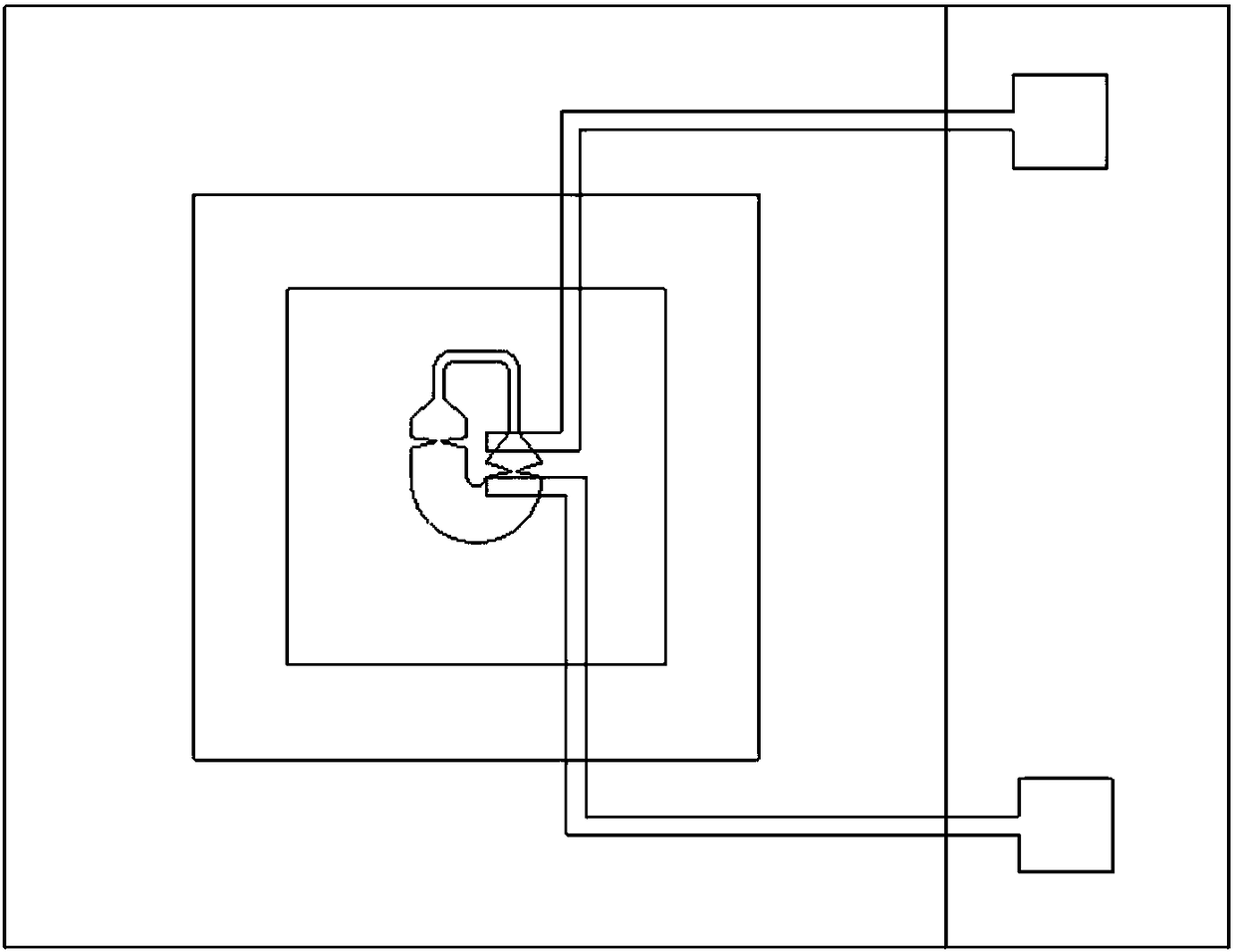

[0032] combine Figure 1-4 , a high-impact inertial microfluidic power switch of the present invention includes a base 1, a cover plate 2, two metal electrodes 3, a microchannel 5, and metal droplets; the cover plate 2 is located at the upper end of the base 1, between the two The substrate 1 is provided with a microchannel 5, and the metal electrode 3 is arranged on the cover plate 2; the microchannel 5 includes a U-shaped liquid reservoir 6, a first capillary valve 7, and a second capillary valve 8 , the third capillary valve 9, the fourth capillary valve 10, the fifth capillary valve 12, the sixth capillary valve 13, the seventh capillary valve 14, the eighth capillary valve 15, the gas guide channel 11; In the reservoir 6; the first capillary valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com