Micro-geometric sense measuring device based on nano-measuring machine and micro-tactometering head

A technology of nano measuring machine and measuring device, which is applied in the direction of measuring device, electromagnetic measuring device, and the measurement of the change force of optical properties of materials when they are stressed, which can solve the interference of measurement environment, cannot realize three-dimensional measurement, and cannot meet Micro-nano processing technology measurement requirements and other issues, to achieve the effect of improving the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The micro geometric measurement device based on the nano measuring machine and the micro tactile probe of the present invention will be described in detail below in conjunction with the embodiments.

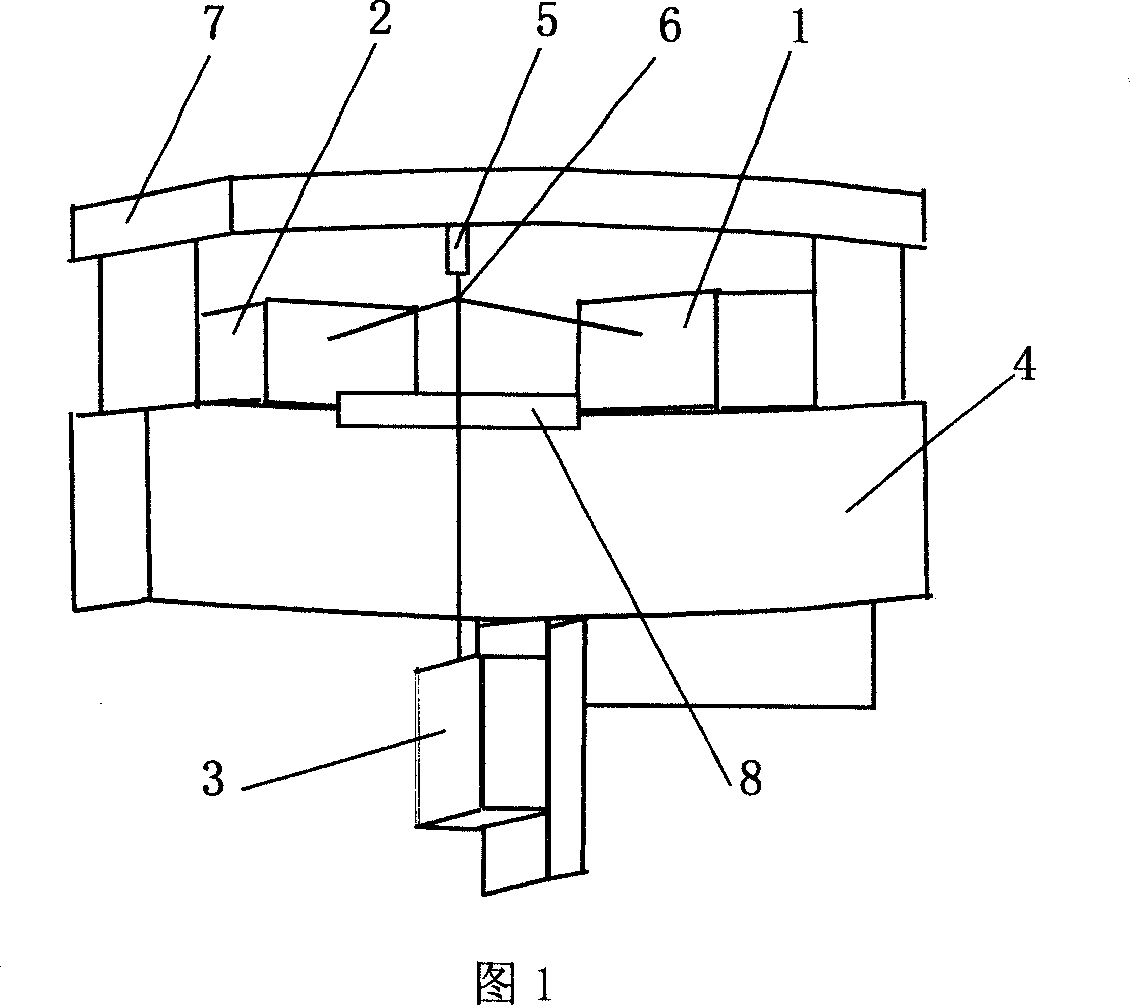

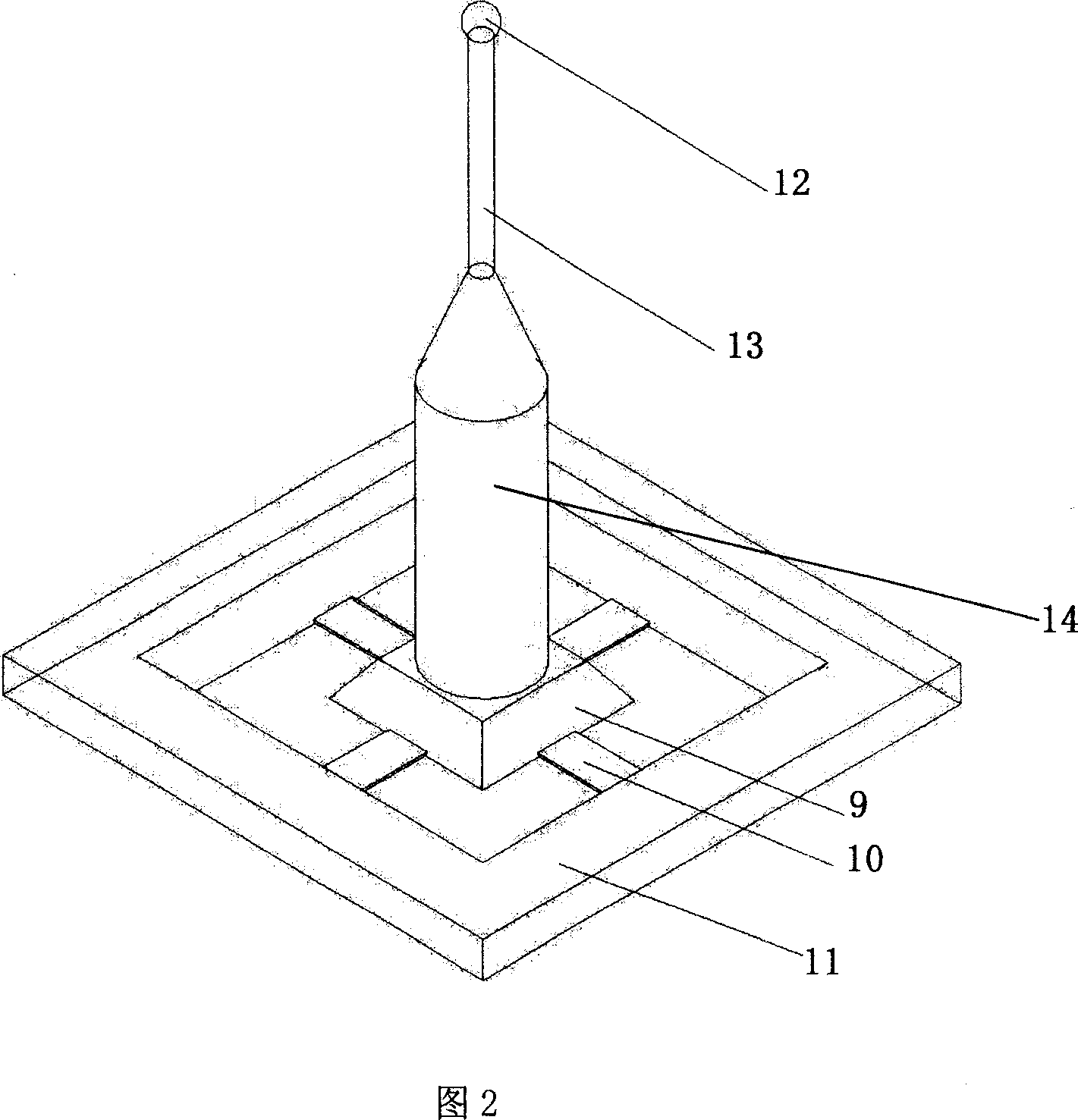

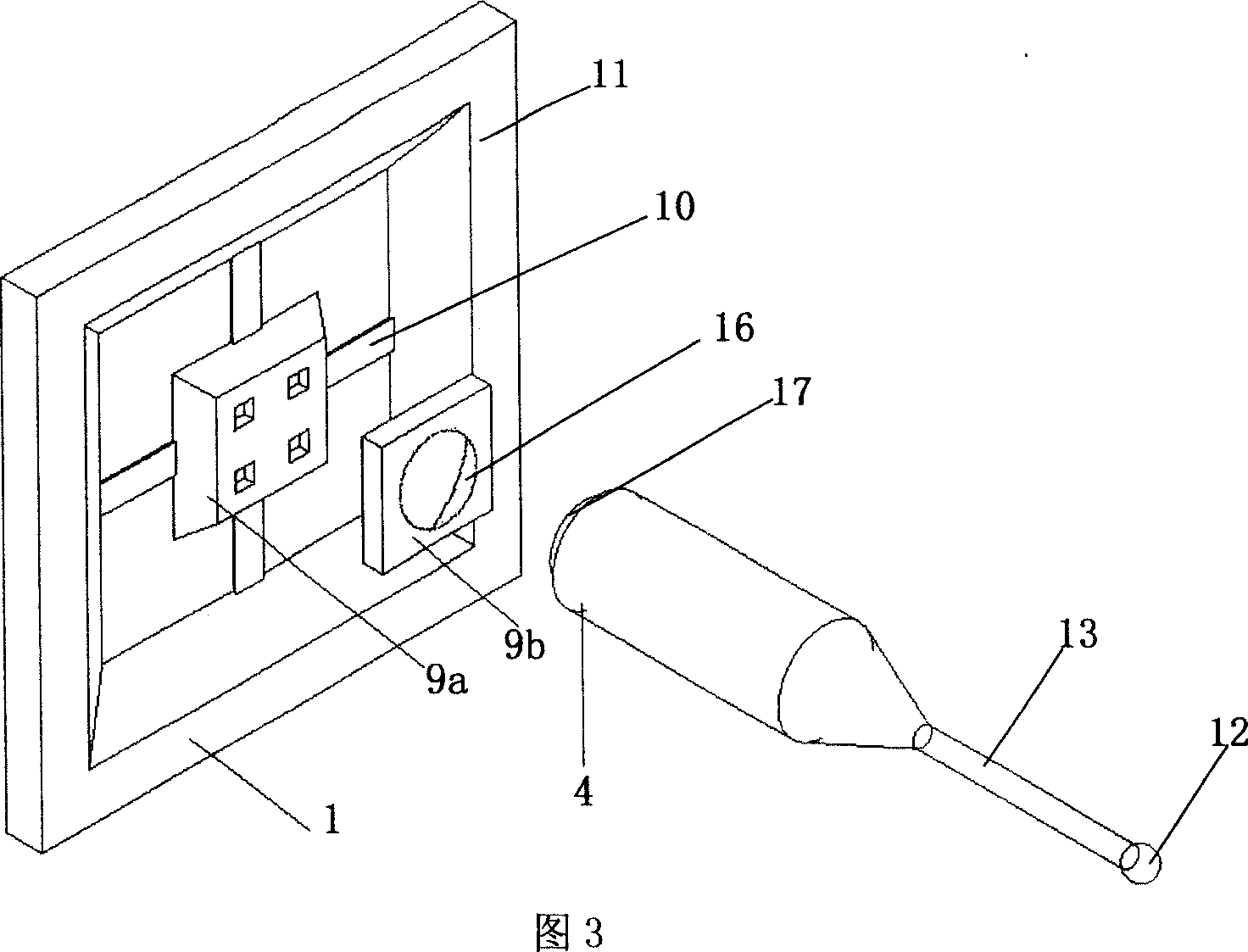

[0039] The micro-geometry measurement device based on the nanometer measuring machine and the micro-tactile probe of the present invention includes the nanometer measuring machine as a positioning measurement platform, and is also provided with a piezoresistive detection system capable of measuring the geometric quantities of micro devices and microstructures. The micro-tactile measuring head system 5 is fixed on the upper part of the nano-measuring machine through the fixing bracket 7 arranged on the upper part of the nano-measuring machine.

[0040] As shown in Figure 1, the described nanometer measuring machine as the positioning measurement platform is a nanometer measuring machine with high precision and wide range, including: an electric control part; a glass stage 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com