Large-sized mechanical equipment structure dynamic simulation test method

A large-scale mechanical and similar test technology, which is applied in the testing of machines/structural components, vibration testing, measuring devices, etc., can solve the problems of inability to perform hammer test of the whole machine, high cost of dynamic characteristic testing instruments and solutions, and lack of large-scale mechanical equipment, etc. problem, to achieve the effect of reducing scale, reducing test cost, and accurate direct test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

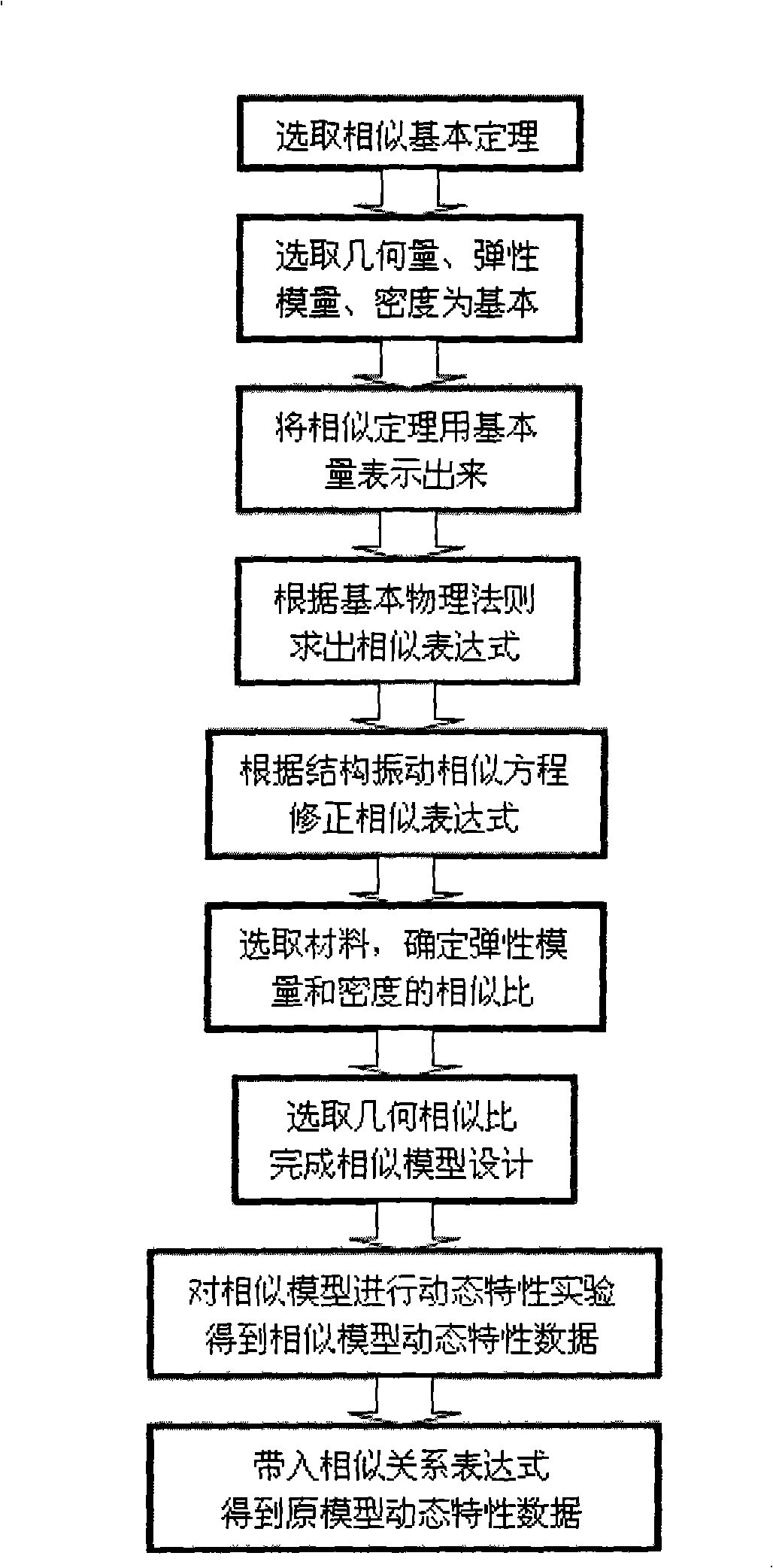

[0021] Such as figure 1 Shown, method flow process of the present invention is as follows:

[0022] step one:

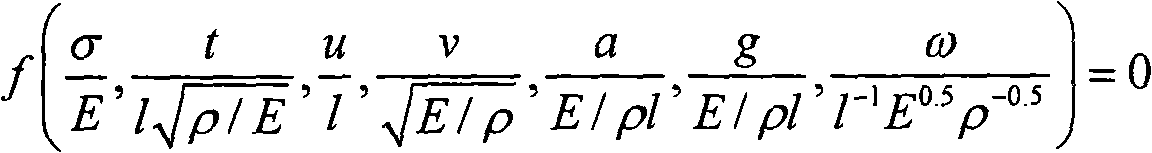

[0023] (1) Select the basic similarity theorem to determine the relevant physical quantities involved in the design of similar models. These relevant physical quantities include: all physical quantities include: σ stress, l geometric quantity, E elastic modulus, ρ density, t time, u displacement, v velocity , a acceleration, g gravity acceleration, ω natural vibration frequency;

[0024] (2) Determine geometric quantity (can be length, height, radius, etc.), density, elastic modulus as basic physical quantity;

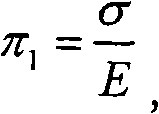

[0025] (3) Express the other physical quantities in the basic similarity theorem (referring to all physical quantities except the basic physical quantities) with basic physical quantities, and realize the dimensionless of the similarity theorem.

[0026] Step two:

[0027] (4) List the basic physical laws involved in designing similar models, based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com