Method for grinding crankshaft of diesel engine accurately

A diesel engine and crankshaft technology, which is applied in the field of diesel engine crankshaft processing, can solve problems such as exceeding the standard, low efficiency, and out-of-tolerance axial dimensions of the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

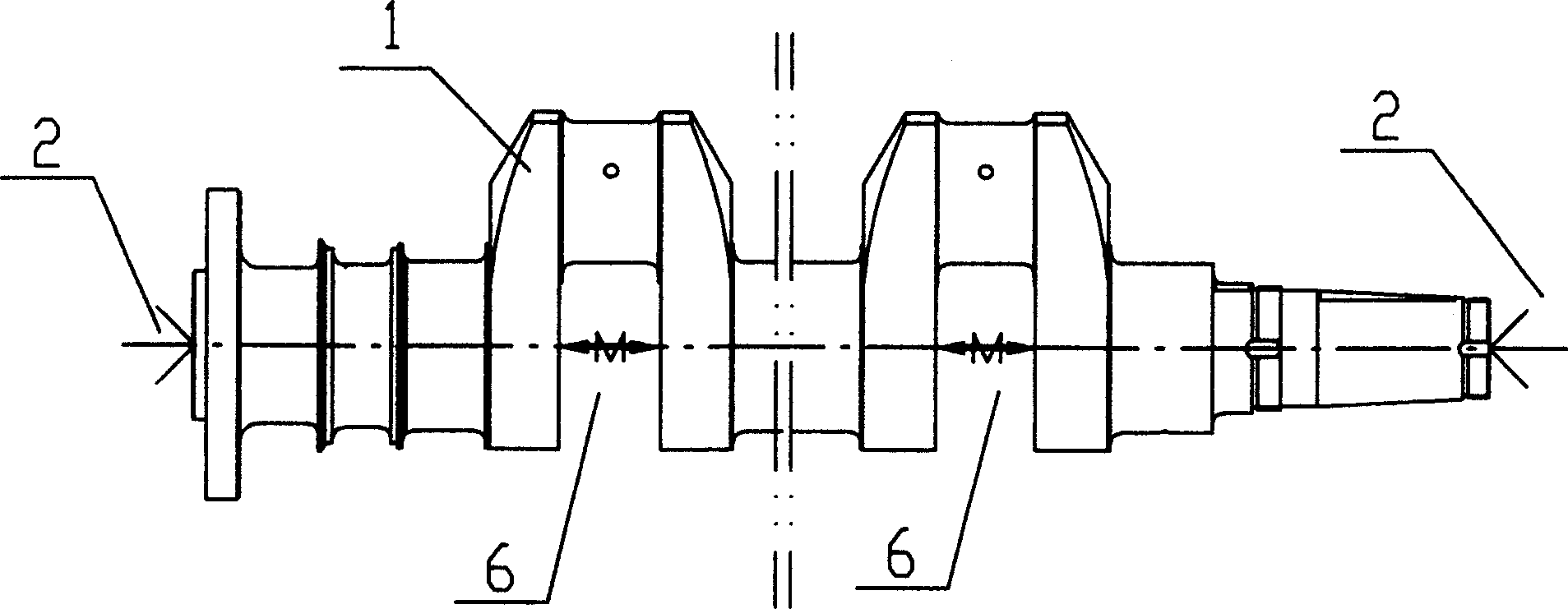

[0014] Such as figure 1 , figure 2 As shown, the precise grinding method of diesel engine crankshaft includes the following steps:

[0015] The first step of placing the workpiece: place the crankshaft 1 between the two tops 2 of the workbench of the grinding machine, and initially fix the workpiece on the workbench with a small clamping force;

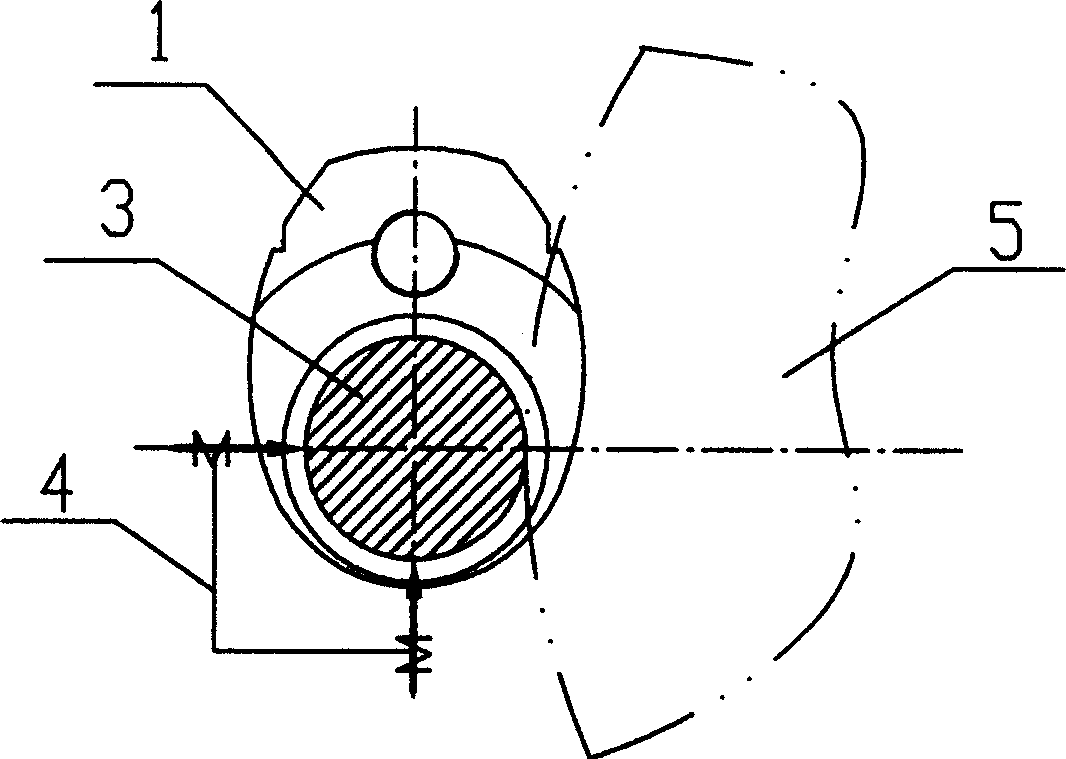

[0016] The second step is to place the main shaft support step: at least one corresponding main shaft support 4 is set at a plurality of main shaft parts 3 of the crankshaft, and the main shaft support has a pressing force upward to the main shaft part and overcomes the gravity deformation of the crankshaft. The bracket also has a thrust applied to the grinding point of the grinding wheel 5 to overcome the grinding thrust of the grinding wheel to the crankshaft, and the pressing force and thrust of the main shaft bracket 4 are adjustable;

[0017] The third step of crankshaft pre-deformation step: at each crankshaft of the cranksha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com