Cross-wedge rolled piece machining device and method

A processing device and a technology of cross wedge rolling, applied in the field of processing devices of parts, can solve the problems of performance degradation and errors of cross wedge rolling parts, and achieve the effects of uniform force, reduced damage, strong execution and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

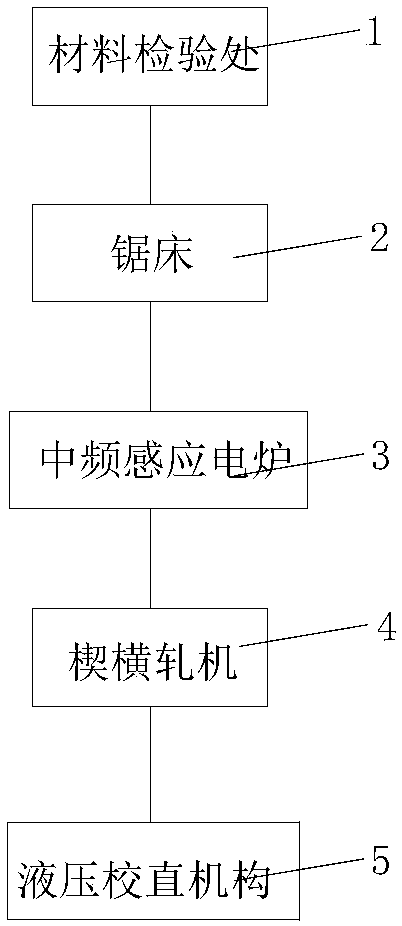

[0059] Such as figure 1 As shown, this embodiment includes a material inspection station 1, a sawing machine 2, an intermediate frequency induction furnace 3, a cross wedge rolling mill 4, a cooling transport device 6, and a hydraulic straightening mechanism 5 through which the cross wedge rolled piece passes sequentially;

[0060] In the material inspection department, use the pre-furnace spectrum analyzer, acid etching visual inspection, Brinell hardness tester, microscope, and ultrasonic flaw detector to inspect the material composition, low-magnification structure, end hardenability, band structure, and interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com