Filter device for separating gas and solid

A technology of gas-solid separation and filtration device, which is applied in the direction of dispersed particle filtration, separation method, and dispersed particle separation, etc. It can solve problems such as plugging holes, high energy consumption, and unsatisfactory cleaning effect of backflushing airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

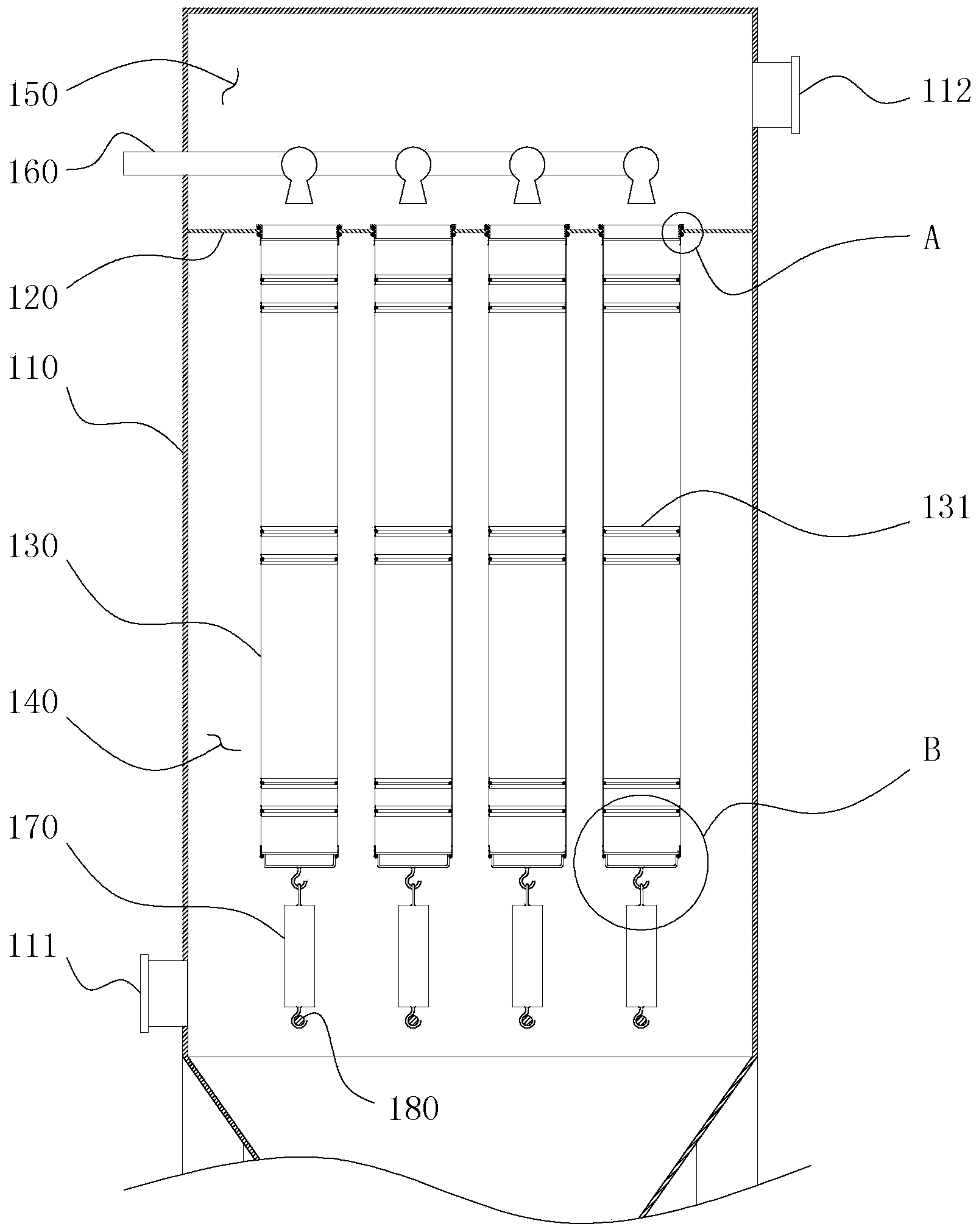

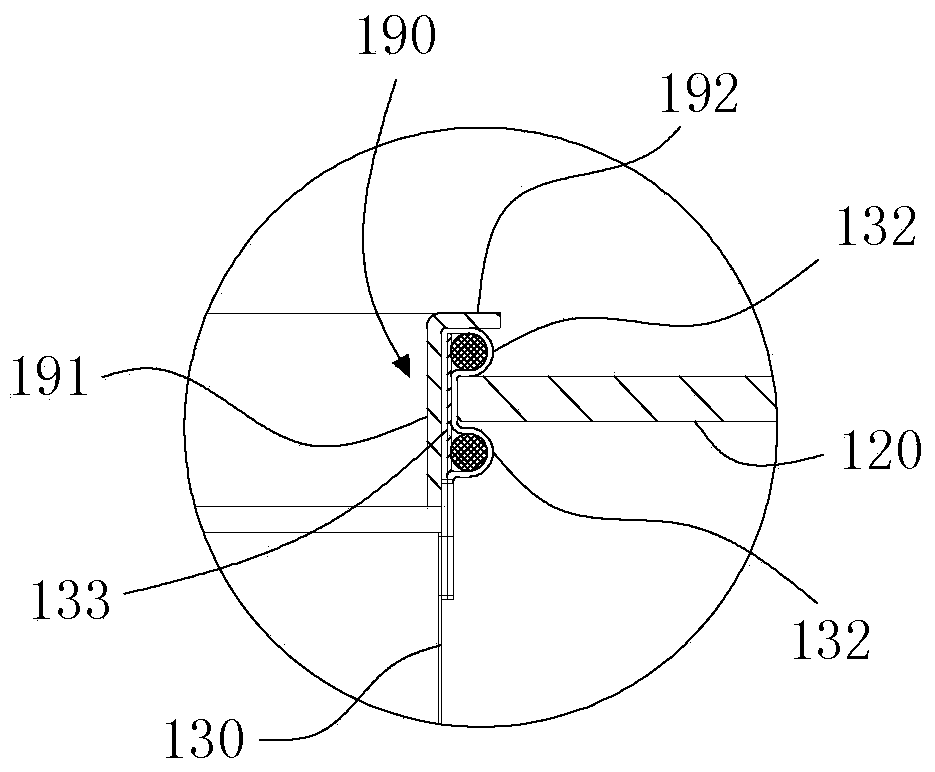

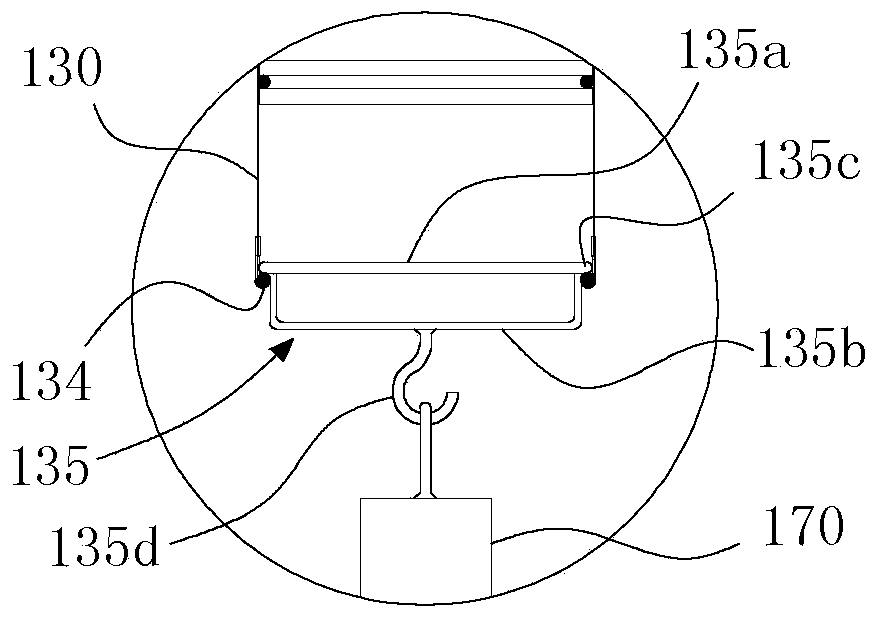

Embodiment 1

[0020] The blast furnace gas is filtered by using the filter device in the above specific embodiment. Wherein the bag body of the filter bag is composed of the expanded polytetrafluoroethylene membrane and the inner tank made of glass fiber woven cloth. The thickness of the liner is only 0.3 mm, its longitudinal tensile strength is 570KN / m, and its transverse tensile strength is 410KN / m. The filter bag 130 has a length of 1 meter and a diameter of 300 mm. There is neither an anti-flat ring nor a supporting structure such as a bag cage on the filter bag. The pulling force applied by each elastic pulling device to the corresponding filter bag is set at 25 kg. During normal filtration, the gas to be filtered enters the raw gas chamber 140 from the air inlet 111, and then enters the clean gas chamber 150 through the filter bag under the filtration pressure, and the filtered gas is discharged from the exhaust port 112; when the filter bag surface is attached After a certain thic...

Embodiment 2

[0022] The blast furnace gas is filtered by using the filter device in the above specific embodiment. Wherein the bag body of the filter bag is composed of the expanded polytetrafluoroethylene membrane and the inner tank made of glass fiber woven cloth. The thickness of the liner is 0.5 mm, its longitudinal tensile strength is 580KN / m, and its transverse tensile strength is 430KN / m. The filter bag 130 has a length of 12 meters and a diameter of 300 millimeters. An anti-flat ring 131 is arranged on the filter bag. The pulling force applied by each elastic pulling device to the corresponding filter bag is set at 40 kg. During normal filtration, the gas to be filtered enters the raw gas chamber 140 from the air inlet 111, and then enters the clean gas chamber 150 through the filter bag under the filtration pressure, and the filtered gas is discharged from the exhaust port 112; when the filter bag surface is attached After a certain thickness of dust, the blowback device 160 ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com