Method for enhancing hard turning circularity of thin-wall annular parts

A technology of hard turning and circular ring, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of triangle roundness error contour, affecting machining accuracy, multiple clamping, etc., to improve the roundness of turning, Achieve high-precision manufacturing and prevent radial deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

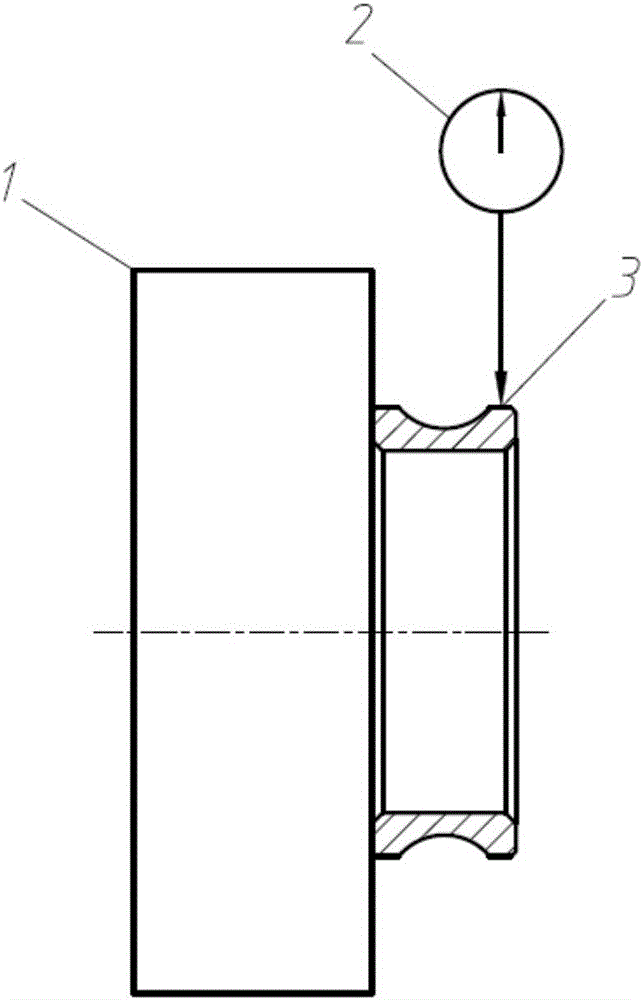

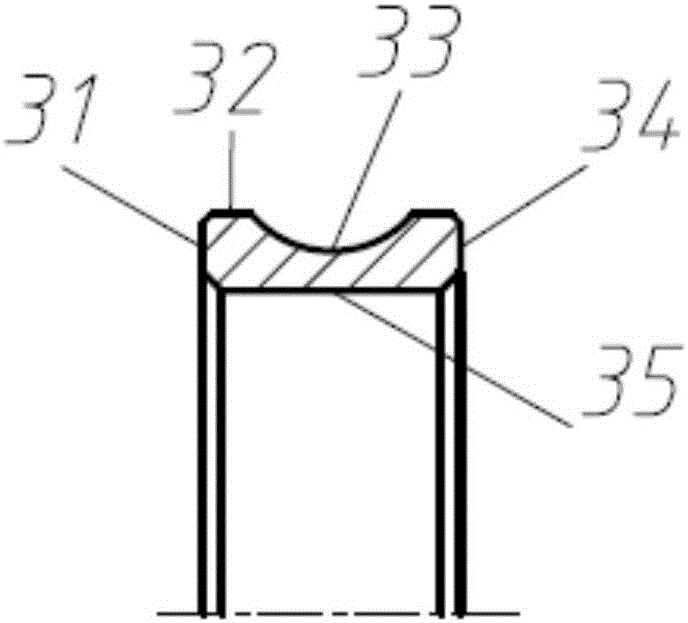

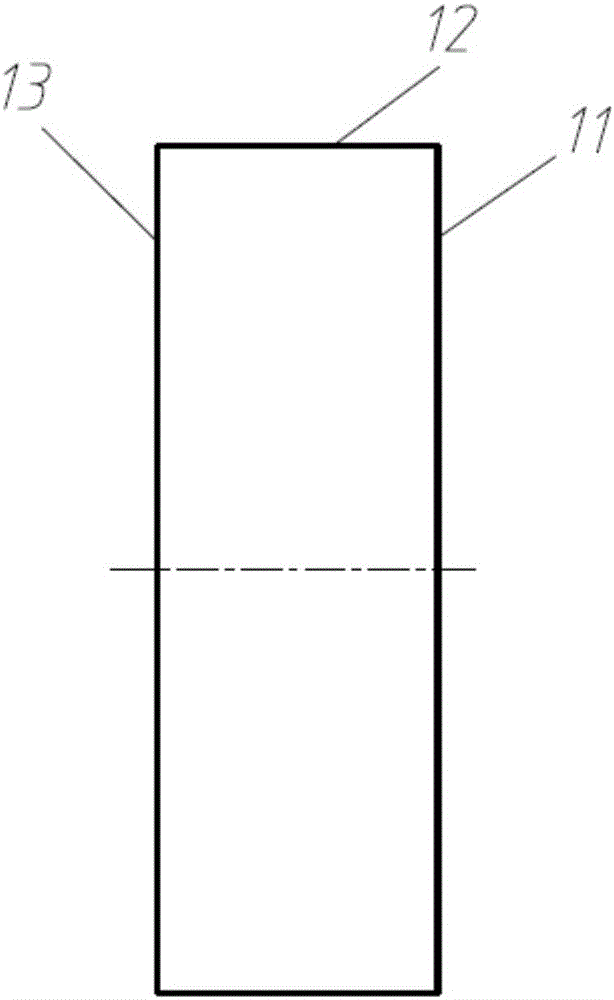

[0039] refer to Figure 1-4 , in this embodiment, the thin-walled annular parts are the inner ring 3 of a single row angular contact ball bearing, including a positioning end face 31, an outer circular surface 32, an outer groove or outer raceway 33, a non-locating end face 34, and an inner circular surface 35 ; The fixture is a magnetic chuck 1, including a clamping positioning surface 11, an outer circular surface 12, and a surface 13 connected with the lathe spindle head.

[0040] The machining of the inner ring 3 of the single row angular contact ball bearing includes the following steps:

[0041] 1. Prepare the inner ring 3 with machining allowance.

[0042] 2. Perform quenching and tempering heat treatment on the inner ring 3 with machining allowance.

[0043] Among them, the inner ring 3 of the single row angular contact ball bearing is made of GCr15 bearing steel, which is subjected to normal quenching and tempering heat treatment. After heat treatment, the hardness ...

Embodiment 2

[0050] refer to Figure 3-6 , in this embodiment, the thin-walled annular parts are the outer ring 4 of a single row angular contact ball bearing, including a positioning end face 41, an outer circular surface 42, a non-locating end face 43, an inner circular surface 44, an inner raceway or an inner groove 45 ; The fixture is a magnetic chuck 1, including a clamping positioning surface 11, an outer circular surface 12, and a surface 13 connected with the spindle head of the lathe.

[0051] The machining of the outer ring 4 of the single row angular contact ball bearing includes the following steps:

[0052] 1. Prepare the outer ring 4 with machining allowance.

[0053] 2. Perform quenching and tempering heat treatment on the outer ring 4 with machining allowance.

[0054] Wherein, the material of the outer ring 4 is GCr15 bearing steel, which is subjected to normal quenching and tempering heat treatment. After the heat treatment, the hardness of the outer ring 4 should be hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com