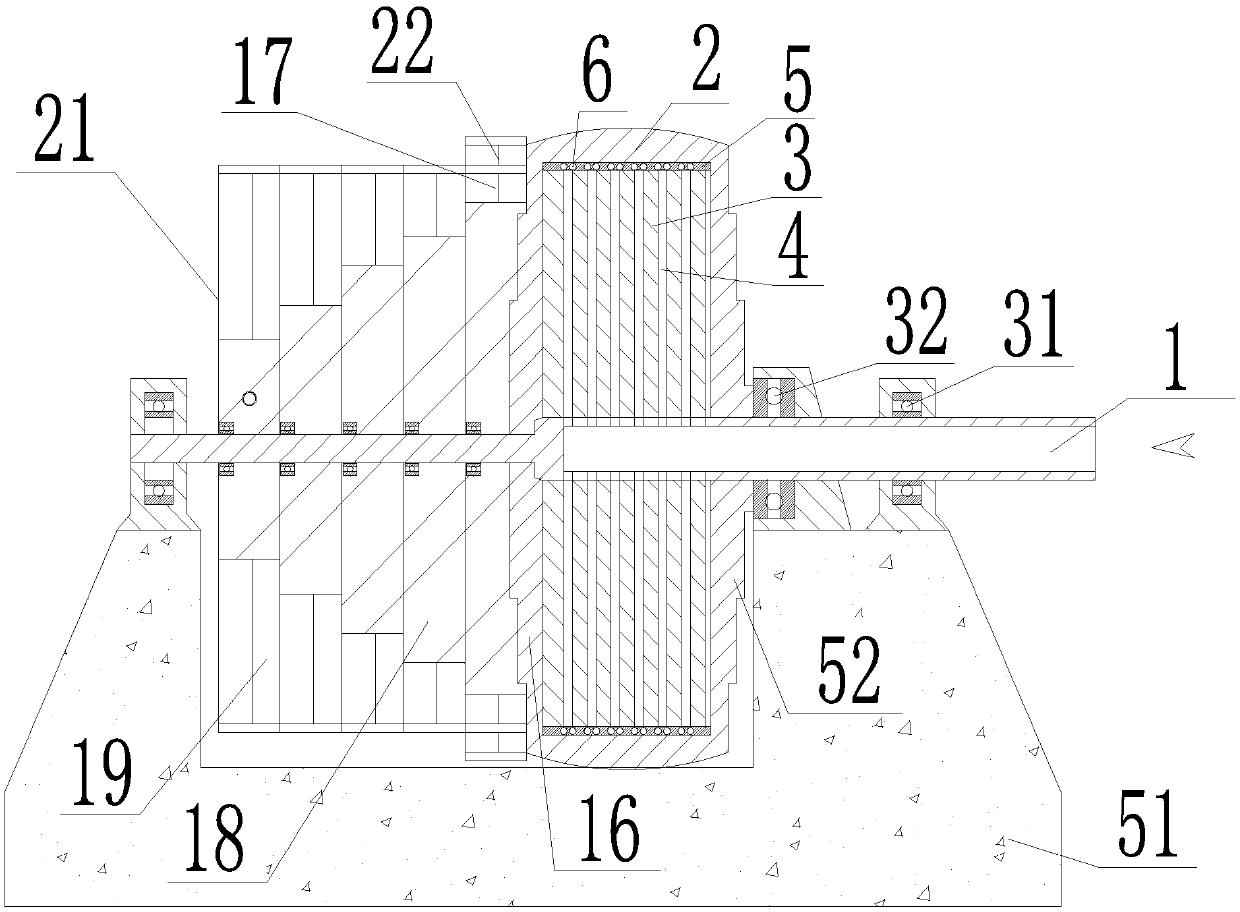

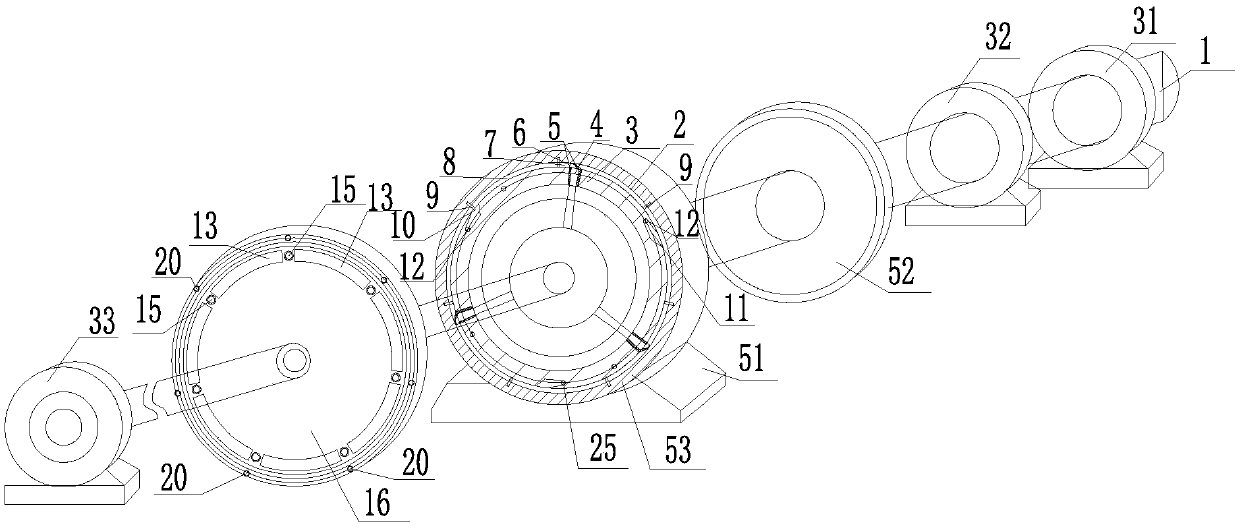

Pressure gas piston injection type rotary engine system for two-time acting application

A rotary engine, pressurized gas technology, applied in the direction of combined engine, non-variable-capacity engine, engine components, etc., can solve the problems of high technical difficulty, high application technical requirements, low thermal efficiency, etc., to improve the utilization rate of thermal efficiency, Improve utilization efficiency, reduce noise and vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1. Applied to large-scale equipment: adding the system equipment of the present invention in the original system application process can change the original application efficiency and increase the output power, so as to achieve a higher use efficiency and achieve the purpose of energy saving, so its The specific implementation mode is a variety of applications, which can change the equipment system; also can increase the mode application of the present invention without changing the original application mode,

[0088] 1), under the pattern of original system application; Increase the equipment of the present invention to form a new application mode, as the use of doing work at the same time;

[0089] 2), independent use of new single equipment: because the new single inventive system has possessed most of the efficiency in the whole application process of pressure gas, can carry out the simultaneous new combination of first-level and second-level equipment as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com