Solar energy underground cross-season heat-storing method

A cross-season, solar energy technology, applied in the field of solar underground cross-season heat storage, can solve problems such as the great influence of geological conditions, and achieve the effects of simple construction, high thermal efficiency utilization rate, and good heat storage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

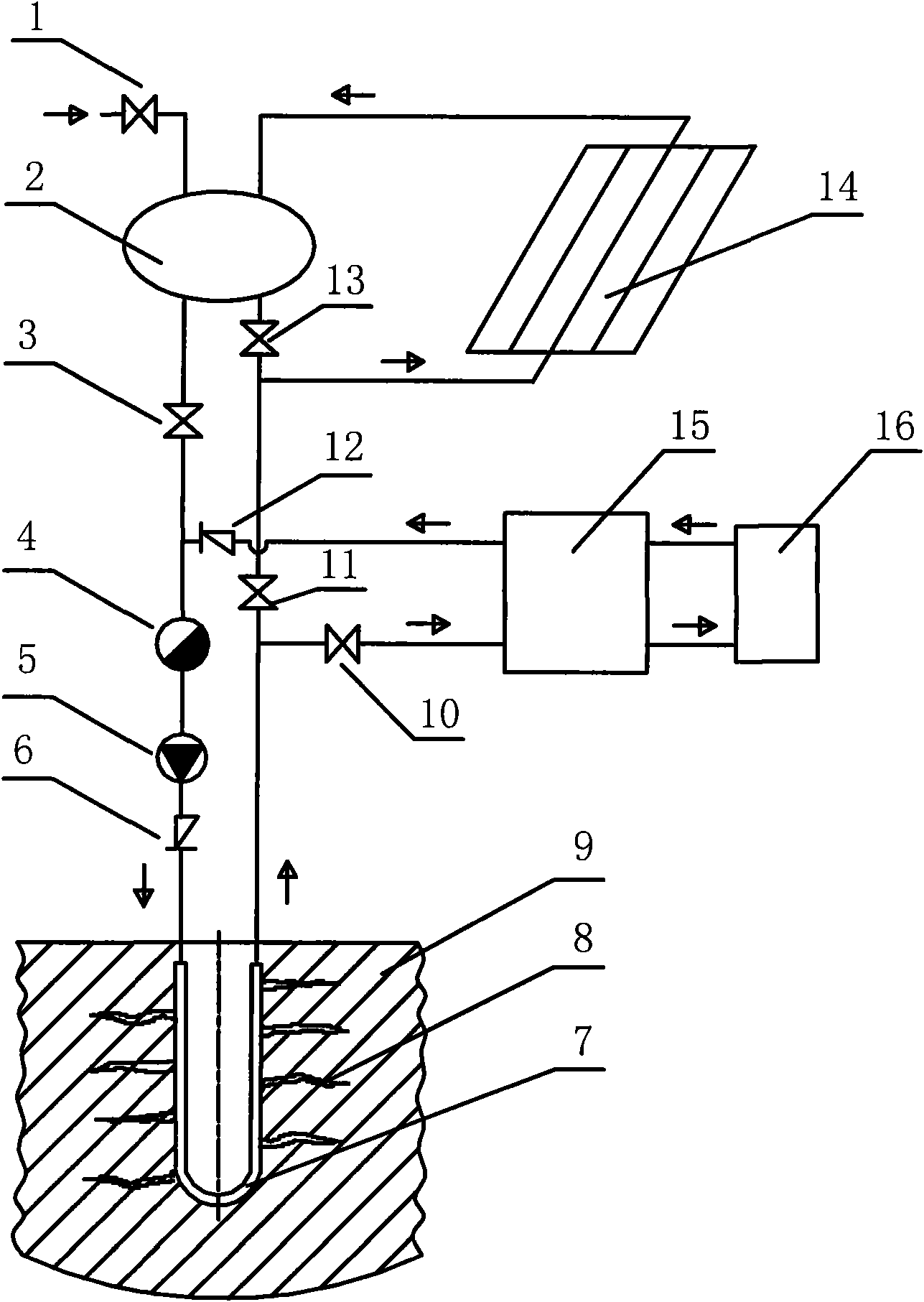

Embodiment 1

[0033] ——In clay stratum areas with poor water permeability:

[0034] According to the design requirements, drill to the design depth, lift the drill to the surface; lower the injection pipe, and lower the injection pipe to the bottom of the hole; prepare high thermal conductivity grout, which includes 25% cement, 6% graphite, and 50% fine quartz Sand, 3% expansion agent, 2% water reducer and 14% water are uniformly mixed; pump the prepared high thermal conductivity grout into the injection pipe through the pump, and spray while spraying, rotating, swinging and lifting Pipe, according to 20MPa injection pressure, 2r / min rotation speed, 40cm / min lifting speed, jet tube swing angle 30°, swing frequency 20 times / min, inject high thermal conductivity grout into clay layer 9, when the jet tube lifts Stop sending high thermal conductivity grouting at the design height; lower the heat exchanger 7, and backfill the heat exchanger 7 to complete the underground construction of the inter...

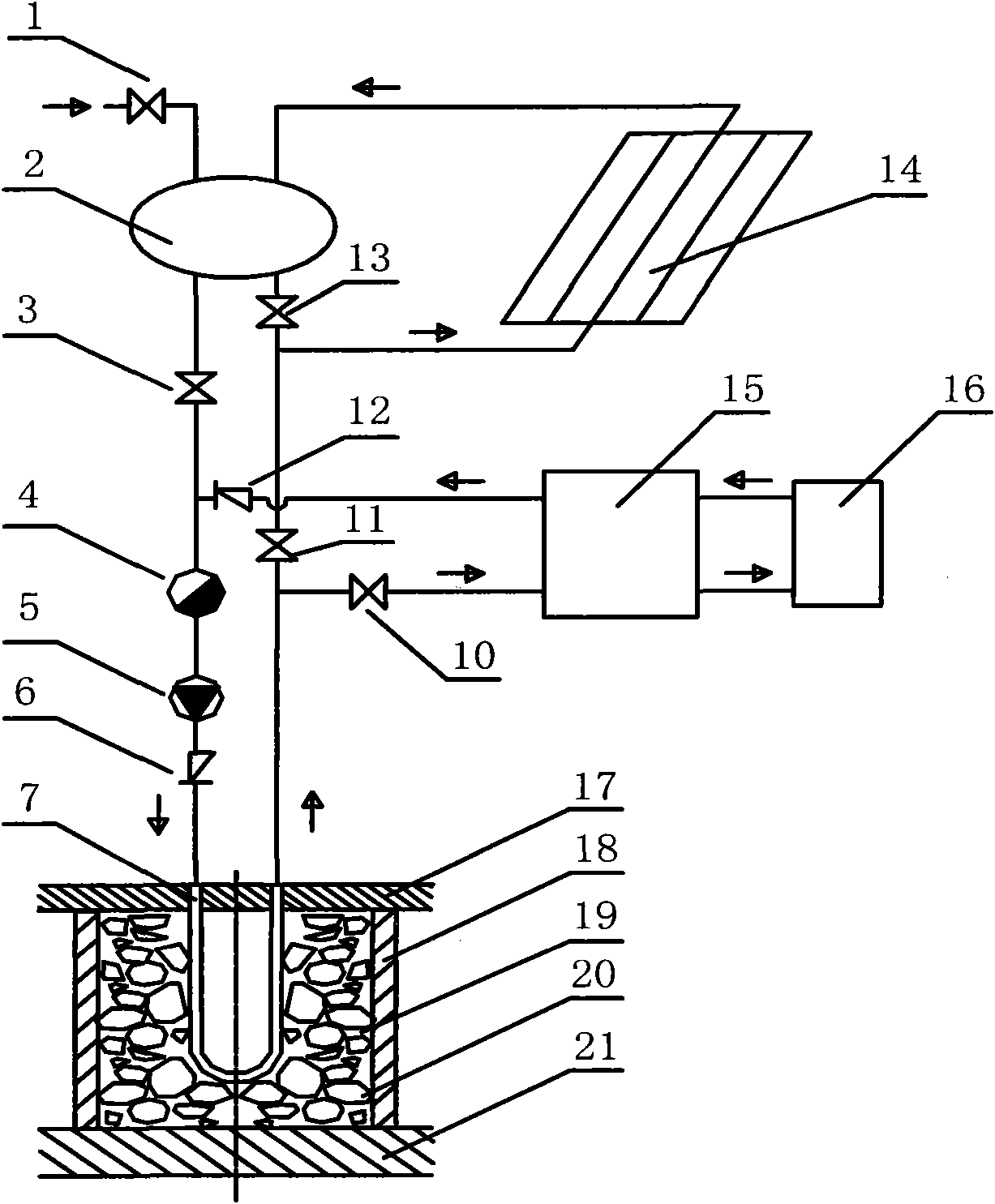

Embodiment 2

[0038] ——In clay stratum areas with poor water permeability:

[0039] Drill to the design depth according to the design requirements, lift the drill to the surface; lower the injection pipe, and lower the injection pipe to the bottom of the hole; prepare high thermal conductivity grouting, high thermal conductivity grouting includes 30% cement, 8% graphite, 40% fine quartz Sand, 3% expansion agent, 2% water reducer and 17% water are uniformly mixed; pump the prepared high thermal conductivity grout into the injection pipe through the pump, and spray while spraying, rotating, swinging and lifting Pipe, according to the injection pressure of 40Mpa, the rotation speed of 3r / min, the lifting speed of 60cm / min, the swing angle of the injection pipe 30°, and the swing frequency of 20 times / min, inject the high thermal conductivity grout into the clay layer 9, when the injection pipe Elevate to the design height and stop sending high thermal conductivity grout; lower the heat exchang...

Embodiment 3

[0043] ——In clay stratum areas with poor water permeability:

[0044] Drill to the design depth according to the design requirements, lift the drill to the surface; lower the jet tube, and lower the jet tube to the bottom of the hole; prepare high thermal conductivity grout, which includes 27% cement, 7% graphite, and 45% fine quartz Sand, 2% expansion agent, 3% water reducing agent and 16% water are uniformly mixed; pump the prepared high thermal conductivity grout into the injection pipe through the pump, and spray while spraying, rotating, swinging and lifting Pipe, according to 30MPa injection pressure, 3r / min rotation speed, 50cm / min lifting speed, injection pipe swing angle 30°, swing frequency 20 times / min, inject high thermal conductivity grout into clay layer 9, when the injection pipe Elevate to the design height and stop sending high thermal conductivity grout; lower the heat exchanger and backfill the heat exchanger to complete the underground construction of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com