A low-temperature granulating method of powdered lactic acid

A technology of powder lactic acid and low-temperature granulation, which is applied in the direction of liquid separation into beads and granulation, which can solve the problems of high energy consumption and difficult process, and achieve the effects of low total cost, improved equipment production efficiency, and reduced total energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

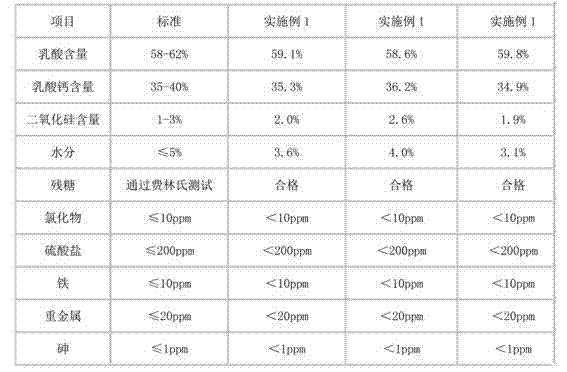

Examples

Embodiment 1

[0022] A low-temperature granulation method for powdered lactic acid, comprising the following steps:

[0023] 1) Heat 900kg of lactic acid with a content of 99.5% to 95°C in a reaction tank, then add 97.6kg of calcium oxide, and add 2kg of silicon dioxide powder after fully reacting to obtain a mixed solution with the content of each component meeting the product requirements;

[0024] 2) Keep the temperature of the mixed solution at 95°C, and then transport the material to the upper nozzle of the fluidized bed spray granulator. After the material is mixed with compressed air at a pressure of 0.2Mpa at the double-layer nozzle, the liquid is sprayed in the form of mist. From the bottom of the granulator, cold air at 5°C is introduced from the bottom of the granulator to contact the sprayed liquid for heat exchange, and the temperature of the cold air drawn from the upper part of the granulator is controlled to be ≤40°C, and the mist liquid is cooled and solidified After that, ...

Embodiment 2

[0027] A low-temperature granulation method for powdered lactic acid, comprising the following steps:

[0028] 1) Heat 900kg of lactic acid with a content of 99.0% to 93°C in a reaction tank, then add 97.6kg of calcium oxide, and add 2kg of silicon dioxide powder after fully reacting to obtain a mixed solution with the content of each component meeting the product requirements;

[0029] 2) Keep the temperature of the mixed solution at 96°C, and then transport the material to the upper nozzle of the fluidized bed spray granulator. After the material is mixed with 0.2Mpa compressed air at the nozzle, the liquid will be sprayed out in the form of mist, from the granulator Cool air at 10°C is passed through the bottom of the granulator to exchange heat with the sprayed mist liquid, and the temperature of the cold air drawn from the top of the granulator is controlled to be ≤40°C, and the mist liquid falls to the ground after cooling and solidifying. The sieve bed at the lower part...

Embodiment 3

[0031] A low-temperature granulation method for powdered lactic acid, comprising the following steps:

[0032] 1) Heat 900kg of lactic acid with a content of 99.3% to 95°C in a reaction tank, then add 97.6kg of calcium oxide, and add 2kg of silicon dioxide powder after fully reacting to obtain a mixed solution with the content of each component meeting the product requirements;

[0033] 2) Keep the temperature of the mixed solution at 95°C, and then transport the material to the upper nozzle of the fluidized bed spray granulator. After the material is mixed with compressed air at a pressure of 0.2Mpa at the double-layer nozzle, the liquid is sprayed in the form of mist. From the bottom of the granulator, cold air at 14°C is introduced from the bottom of the granulator to contact the sprayed liquid for heat exchange, and the temperature of the cold air drawn from the upper part of the granulator is controlled to be ≤40°C, and the mist liquid is cooled and solidified After that,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com