Multilayer rapid temperature rising type electric heater containing graphene and aluminum alloy

An aluminum alloy and graphene technology, applied in the field of multi-layer rapid heating electric heaters, can solve the problems of low heat utilization rate, graphene heating installation cost and high power consumption, so as to improve the visual sensory experience and reduce installation Effect of high cost and power consumption, thermal efficiency and heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

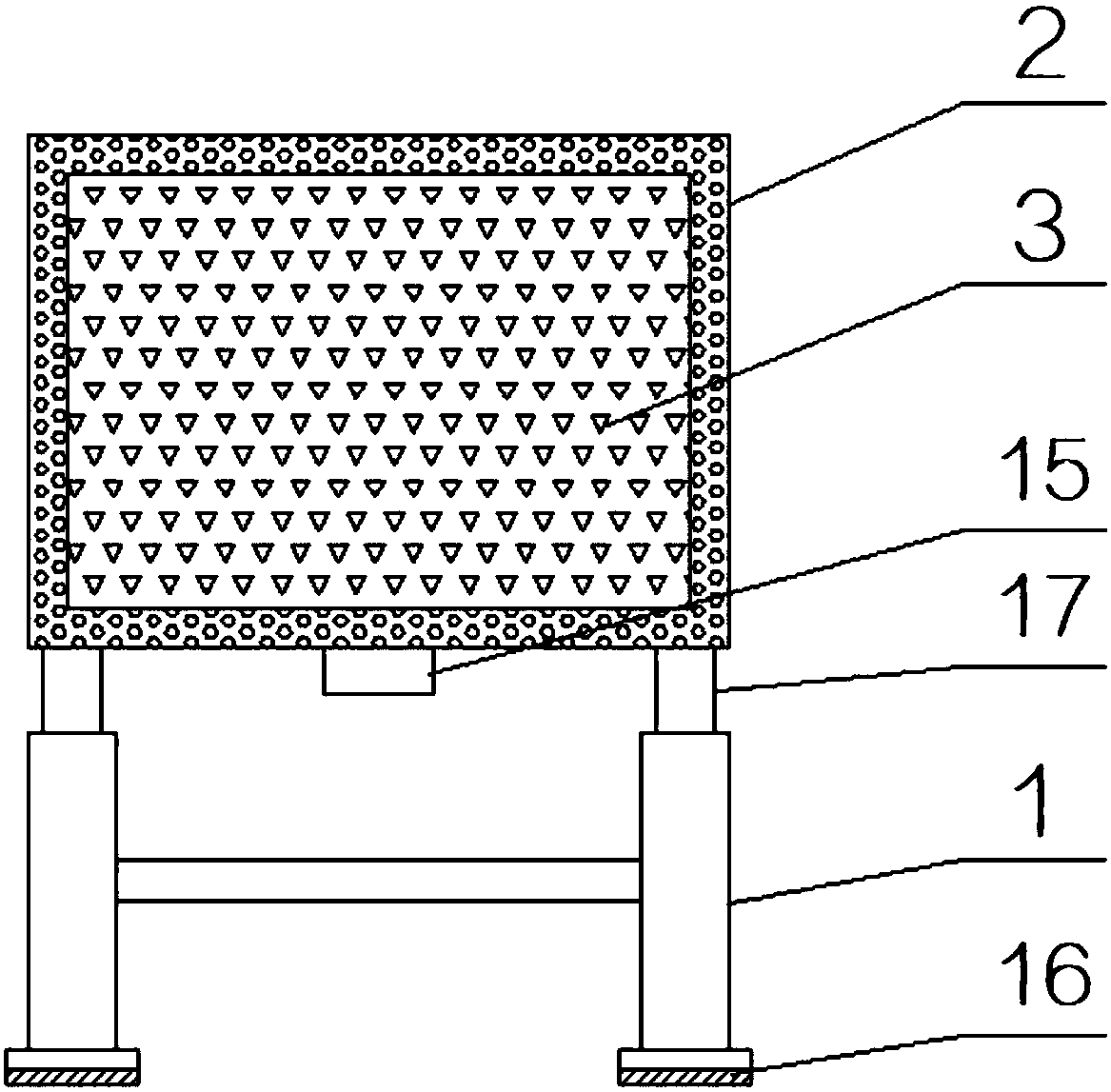

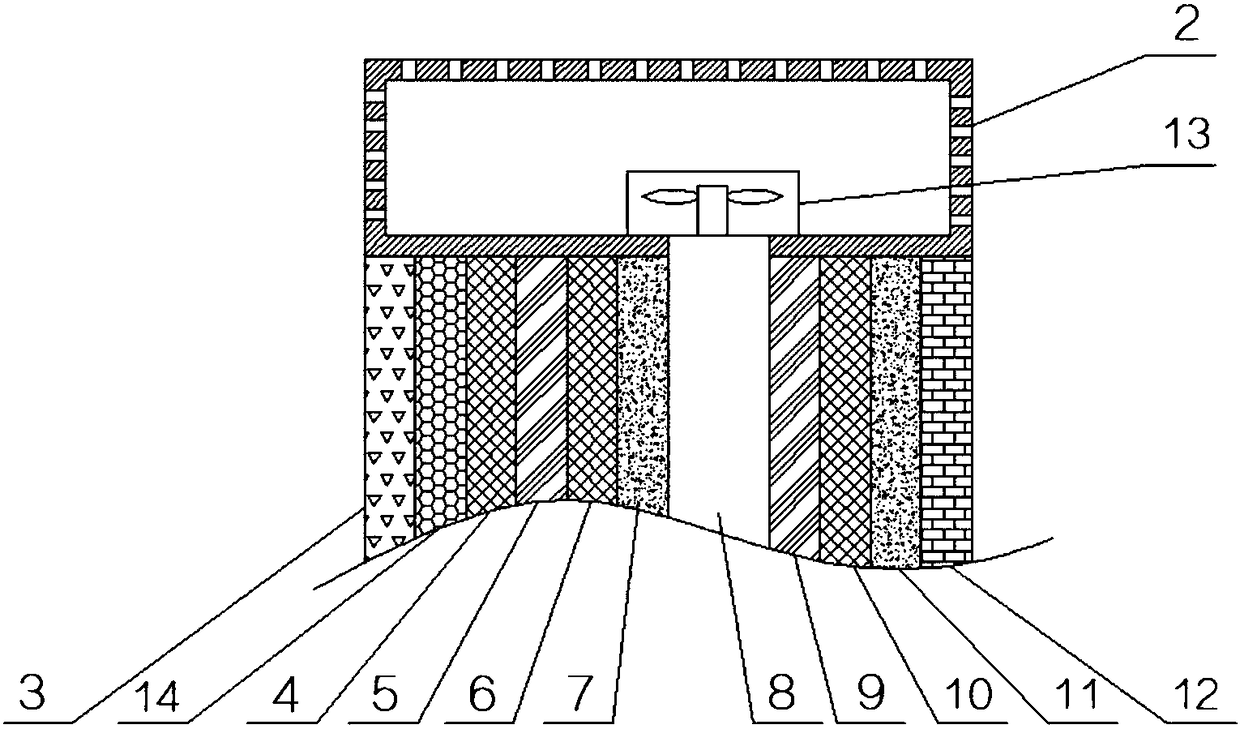

[0031] Such as Figure 1-3 As shown, a multi-layer rapid heating electric heater containing graphene and aluminum alloy includes a controller, a bracket 1, a hollow square frame 2 and a multi-layer heating mechanism;

[0032] The hollow square frame 2 is arranged around the multi-layer heating mechanism, the hollow square frame 2 is arranged on the support 1, the material of the hollow square frame 2 is aluminum alloy, and several hollow square frames 2 are arranged on vent hole;

[0033] The multi-layer heating mechanism includes an aluminum alloy front plate 3, a first insulating layer 4, a first graphene heating film 5, a second insulating layer 6, a first heat reflecting heat preservation layer 7, and a cavity 8 from front to back. , the second graphene heating film 9, the third insulating layer 10, the second heat reflection insulation layer 11 and the back plate 12, the aluminum alloy front plate 3 is provided with several ventilation micro-holes;

[0034] The side of ...

Embodiment 2

[0039] On the basis of Embodiment 1, a tourmaline pad 14 is provided between the aluminum alloy front plate 3 and the first insulating layer 4 .

[0040] A temperature sensor is arranged between the aluminum alloy front plate 3 and the tourmaline pad 14, and the temperature sensor is electrically connected to the controller.

[0041] A remote control device is also included, and the remote control device is electrically connected with the controller.

[0042] A display panel 15 is provided at the bottom of the hollow square frame 2, and the display panel 15 is electrically connected to the controller.

[0043] In this embodiment, a multi-layer rapid heating electric heater containing graphene and aluminum alloy, a tourmaline pad 14 is arranged between the aluminum alloy front plate 3 and the first insulating layer 4, which has an excellent health care effect on the human body ; It also includes a remote control device, so that the electric heater can be controlled remotely, w...

Embodiment 3

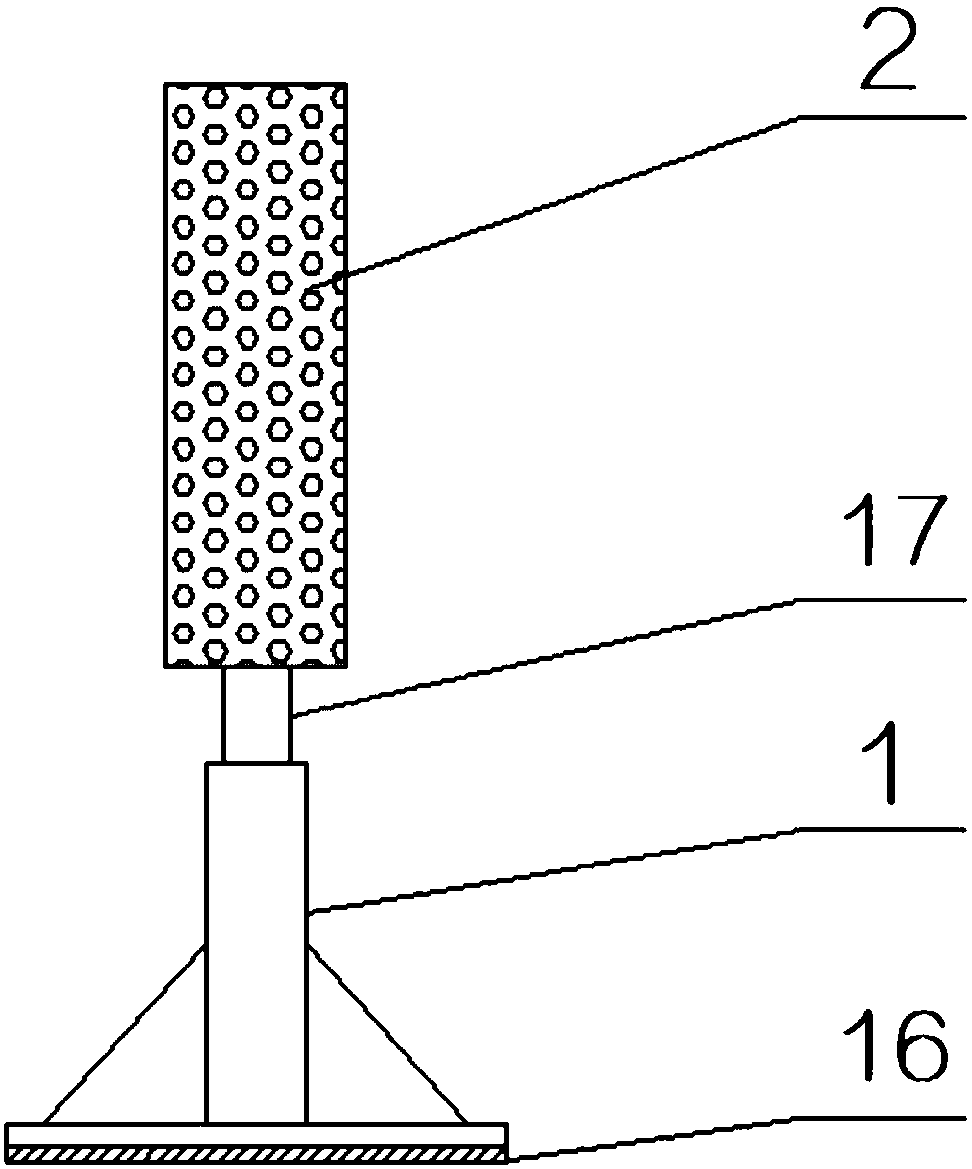

[0045] On the basis of Embodiment 2, a rubber pad 16 is provided at the bottom of the bracket 1 .

[0046] A lifting device 17 is also included, and the hollow square frame 2 is arranged on the support 1 through the lifting device 17 .

[0047] Both the aluminum alloy front panel 3 and the rear panel 12 are provided with decorations.

[0048] A kind of multi-layer fast heating electric heater containing graphene and aluminum alloy of this embodiment, the bottom of bracket 1 is provided with rubber pad 16, has improved the stability of device; Hollow square frame 2 is arranged on bracket 1 by lifting device 17 , so that the heating area can be flexibly adjusted, and the whole device can be placed anywhere; the aluminum alloy front panel 3 and the rear panel 12 are provided with decorations, so that the user can enhance the visual sensory experience while heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com