Alcohol-based fuel formed by utilizing waste alcohol azeotrope and preparation method of alcohol-based fuel

An alcohol-based fuel and an azeotrope technology, applied in the field of alcohol-based fuel and its preparation, can solve the problems of complex azeotropic distillation process and high energy consumption, reduce the generation of waste water and other by-products, reduce the cost of raw materials, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

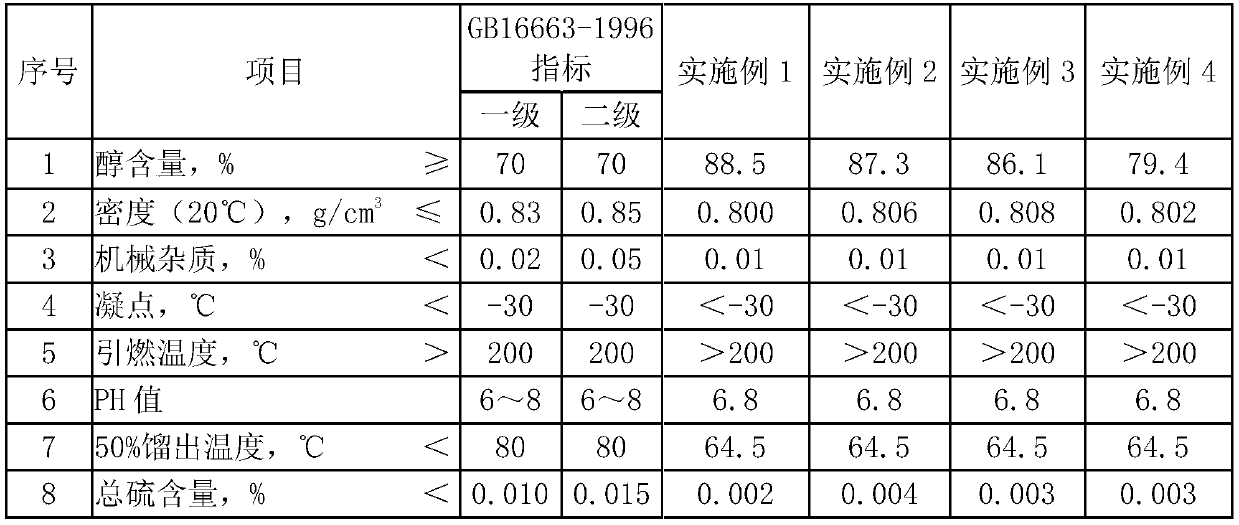

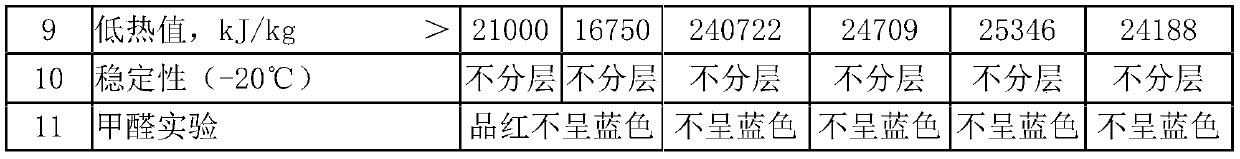

Examples

Embodiment 1

[0022] The preparation method of the alcohol-based fuel that utilizes waste alcohol azeotrope to form comprises the following steps:

[0023] Take by weight the ternary azeotrope of methanol, isopropanol-water azeotrope, ethyl acetate-ethanol-water, 60 parts of methanol, 10 parts of isopropanol-water azeotrope and 5 parts of Ethyl acetate-ethanol-water ternary azeotrope; the mass content of isopropanol in the isopropanol-water azeotrope is 87.9%, ethyl acetate in the ethyl acetate-ethanol-water ternary azeotrope: ethanol : water=83:9:8 (mass ratio). Add it into the reaction kettle one by one, turn on the stirring device of the reaction kettle, control the stirring speed to 300 rpm, and then add 1 part of additives; stir until the materials are evenly mixed, and the product is obtained. Methanol was recovered methanol at a concentration of 98%.

Embodiment 2

[0025] The preparation method of the alcohol-based fuel that utilizes waste alcohol azeotrope to form comprises the following steps:

[0026] Weigh the ternary azeotrope of methanol, isopropanol-water azeotrope, ethyl acetate-ethanol-water according to parts by mass, including 80 parts of methanol, 20 parts of isopropanol-water azeotrope and 10 parts The ethyl acetate-ethanol-water ternary azeotrope; The mass content of isopropanol in the isopropanol-water azeotrope is 87.9%, ethyl acetate in the ethyl acetate-ethanol-water ternary azeotrope: Ethanol: water = 83:9:8 (mass ratio). Add it into the reaction kettle one by one, turn on the stirring device of the reaction kettle, control the stirring speed to 400 rpm, and then add 3 parts of additives; stir until the materials are evenly mixed, and the product is obtained. Methanol was recovered methanol at a concentration of 98%.

Embodiment 3

[0028] The preparation method of the alcohol-based fuel that utilizes waste alcohol azeotrope to form comprises the following steps:

[0029] Weigh methanol, isopropanol-water azeotrope, ethyl acetate-ethanol-water ternary azeotrope in parts by mass, including 70 parts of methanol, 15 parts of isopropanol-water azeotrope and 8 parts The ethyl acetate-ethanol-water ternary azeotrope; The mass content of isopropanol in the isopropanol-water azeotrope is 87.9%, ethyl acetate in the ethyl acetate-ethanol-water ternary azeotrope: Ethanol: water = 83:9:8 (mass ratio). Add it into the reaction kettle one by one, turn on the stirring device of the reaction kettle, control the stirring speed to 350 rpm, and then add 2 parts of additives; stir until the materials are evenly mixed, and the product is obtained. Methanol was recovered methanol at a concentration of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com