Weather-proof and quick-drying pavement damage repairing material and preparation method thereof

A technology for repairing materials and dry pavement, applied in the field of pavement repair, can solve the problems of long open traffic time, easy aging of organic materials, unsatisfactory weather resistance, etc., and achieves outstanding interface bonding performance, excellent road performance, and high early strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

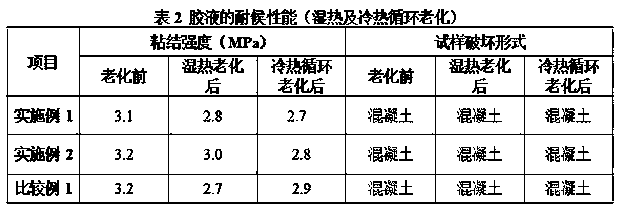

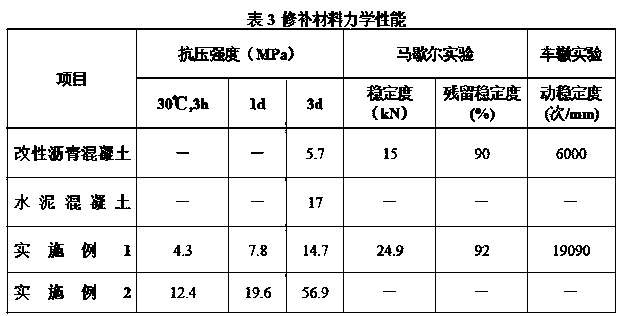

[0039] Weather-resistant and quick-drying pavement damage repair material, made from the following components:

[0040] Component A: 100 parts by mass of epoxy resin E51;

[0041] 15 parts by mass of YDH184;

[0042] 15 parts by mass of active silica powder;

[0043] Component B: 50 parts by mass of modified phenalkamine curing agent;

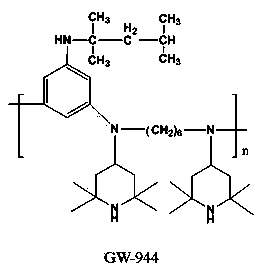

[0044] GW-944 1 mass part;

[0045] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 4:1.

[0046] The aggregate is the tailings of the quarry, and the mass percentages of particles of different particle sizes are:

[0047] Particle size 0.6mm-1.18mm 15%

[0048] Particle size 1.18mm-2.36mm particles 55%

[0049] Particle size 2.36mm-5.00mm 30%.

[0050] Put epoxy resin E51, active diluent YDH184, active silicon micropowder, modified phenalkamine curing agent, hindered amine light stabilizer GW-944 into the mixing tank in turn, stir evenly to form a glue, and mix evenly with the aggregate, tha...

Embodiment 2

[0052] Weather-resistant and quick-drying pavement damage repair material, made from the following components:

[0053] Component A: 100 parts by mass of epoxy resin E51;

[0054] 15 parts by mass of YDH184;

[0055] 20 parts by mass of active silica powder;

[0056] Component B: 70 parts by mass of modified phenalkamine curing agent;

[0057] GW-944 1 mass part;

[0058] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 5:1.

[0059]The aggregate is the tailings of the quarry, and the mass percentages of particles of different particle sizes are:

[0060] Particle size 0.6mm-1.18mm 20%

[0061] Particle size 1.18mm-2.36mm particles 55%

[0062] Particle size 2.36mm-5.00mm 25%.

[0063] Put epoxy resin E51, active diluent YDH184, active silicon micropowder, modified phenalkamine curing agent, hindered amine light stabilizer GW-944 into the mixing tank in turn, stir evenly to form a glue, and mix evenly with the aggregate, that...

Embodiment 3

[0065] Weather-resistant and quick-drying pavement damage repair material, made from the following components:

[0066] Component A: 100 parts by mass of epoxy resin E51;

[0067] 15 parts by mass of YDH184;

[0068] 30 parts by mass of active silica powder;

[0069] Component B: 70 parts by mass of modified phenalkamine curing agent;

[0070] GW-944 1 mass part;

[0071] Component C: aggregate, the ratio of its mass to the sum of the mass of components A and B is 7:1.

[0072] The aggregate is steel slag, and the mass percentages of particles with different particle sizes are:

[0073] Particle size 0.6mm-1.18mm 20%

[0074] Particle size 1.18mm-2.36mm particles 55%

[0075] Particle size 2.36mm-5.00mm 25%.

[0076] Put epoxy resin E51, active diluent YDH184, active silicon micropowder, modified phenalkamine curing agent, hindered amine light stabilizer GW-944 into the mixing tank in turn, stir evenly to form a glue, and mix evenly with the aggregate, that is The weat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com