Rapid-curing conductive adhesive composition and method for preparing same

A rapid curing and composition technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of reduced adhesion and conductivity, reduced work efficiency, increased energy consumption, etc., to improve adhesion and electrical conductivity, reducing corrosion, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

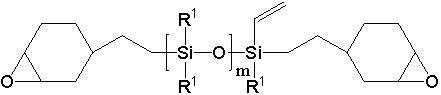

[0033] Step 1. Synthesis of silicon-containing epoxy resin: Pour 2 mol of commercially available 1,2-epoxy-4-vinylcyclohexane and 1 mol of trivinylmethyl polysiloxane (m is 20) into an already In a prepared four-necked round-bottomed flask filled with helium, add 500 mol of tetrahydrofuran solvent under stirring, after mixing uniformly, add 1 mol% of Karstedt catalyst drop by drop, and heat to 120°C. Stirring and constant temperature were maintained for 3 hours. Heating was stopped, the reaction mixture was washed 3 times with 300ml pure water, and then the solvent was distilled off under reduced pressure to obtain oily transparent compound T1 with a yield of 91%. The structural formula of said compound T1 was:

[0034] .

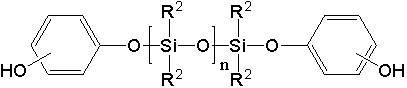

[0035] Step 2. Synthesis of polysiloxane containing phenol groups: Pour 1 mol of dimethoxymethyl hydrogen-containing polysiloxane (n is 6) and 1 mol of p-diphenol into the prepared and helium-filled In a four-necked round-bottomed flask, add 300 mol of ...

Embodiment 2

[0038] Step 1. Synthesis of silicon-containing epoxy resin: Compared with Example 1, except that trivinyl ethyl polysiloxane is used instead of trivinyl methyl polysiloxane, the others are the same. The oily transparent compound T3 was obtained with a yield of 89%.

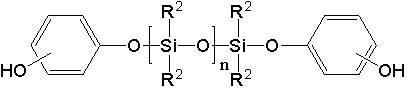

[0039] Step 2, the synthesis of polysiloxane containing phenol group: Compared with Example 1, except that dimethoxyethyl polysiloxane is used instead of dimethoxymethyl polysiloxane, other is the same , obtain oily compound T4, yield 90%, the structure of said compound T4 is:

[0040] .

[0041] Step 3. Preparation of a fast-curing conductive adhesive composition: 100 grams of the compound T3 synthesized above, 42 grams of T4, 0.5 grams of benzylamine-boron trifluoride complex, 7 ppm of Karstedt catalyst, 1-ethynyl- 1-Cyclohexanol 16ppm, flake silver powder 230g, silver-coated aluminum powder 35g, spherical silver powder 15g, aluminum powder 3g are finely measured, and added to a low-speed mixer for rough mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com