Membrane electrode for proton exchange membrane fuel cell and producing method thereof

A proton exchange membrane, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as increased interface resistance, large Nafion concentration gradient, peeling, etc., to enhance vibration resistance, improve high current characteristics, The effect of enhancing proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

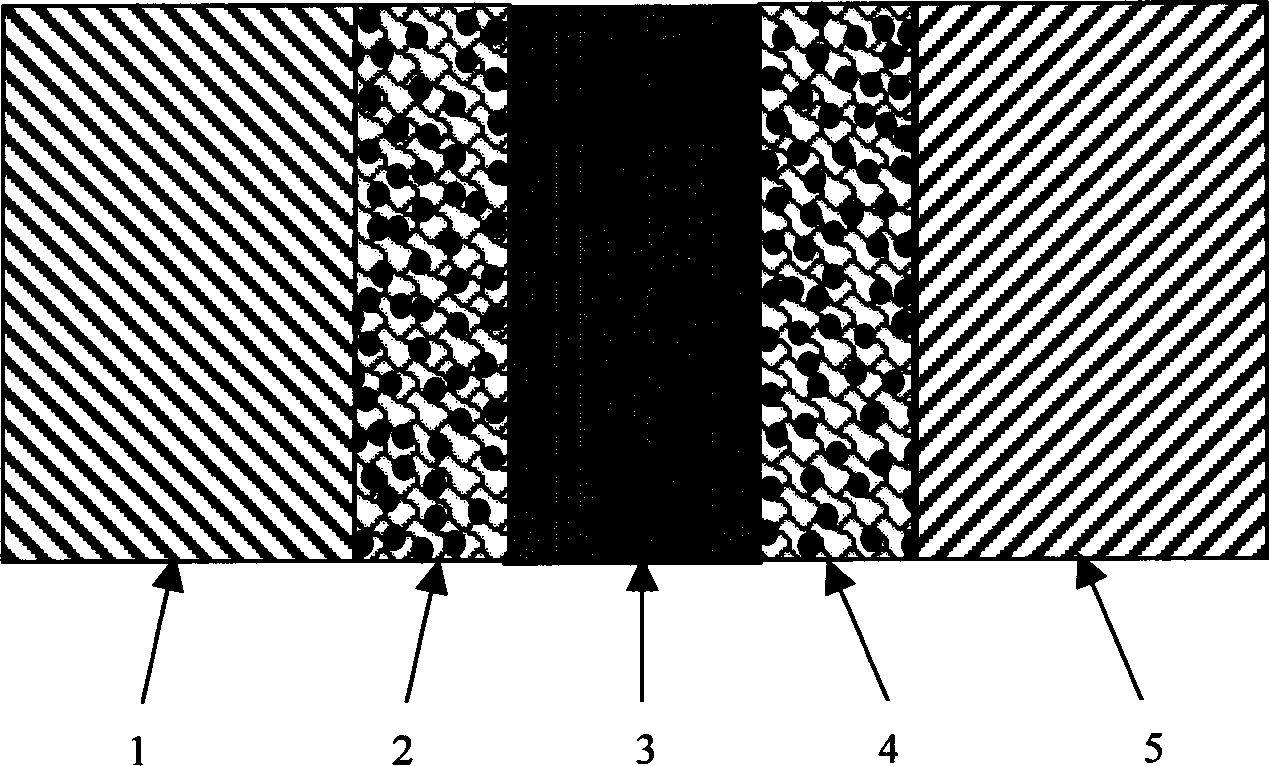

Embodiment 1

[0033] (1) In a stainless steel airtight container, add CHF1000 resin (molar mass EW=1000) from Shandong Dongyue Shenzhou Co., Ltd. into dimethyl sulfoxide, and dissolve it at 200°C to obtain a CHF1000 resin solution, wherein The concentration is 10mg / L;

[0034] (2) With the CHFM1150 film (EW=1100, film thickness about 50 μ m) of Shandong Dongyue Shenzhou Co., Ltd. as the receiving screen, under the condition that the voltage is 30 kV and the distance from the spinneret to the receiving screen is 30 cm, the CHF1000 The resin solution was electrospun into a membrane to obtain a CHFM1150 membrane with a porous fiber membrane on both sides, wherein the fiber diameter was about 90nm, and the thickness of the porous membrane was about 15μm;

[0035] (3) Grinding the carbon-supported Pt catalyst (wherein the Pt content is 20wt%) and 5% CHF1000 resin into ink, and spraying it into the above-mentioned porous fiber membrane to obtain the CHFM1150 membrane with a catalytic layer, the P...

Embodiment 2

[0039] (1) In a stainless steel airtight container, add CHF1000 resin (EW=1000) from Shandong Dongyue Shenzhou Co., Ltd. into dimethylformamide, and dissolve it at 210°C to obtain a CHF1000 resin solution, wherein the concentration of CHF1000 resin 30mg / L;

[0040] (2) With Shandong Dongyue Shenzhou Co., Ltd. CHFM10125 film (EW=1000, film thickness about 125 μ m) as the receiving screen, under the condition that the voltage is 30 kV and the distance from the spinneret to the receiving screen is 20 cm, the CHF1000 resin Electrospinning of the solution to form a membrane to obtain a CHFM10125 membrane with a porous fiber membrane on both sides, wherein the thickness of the porous fiber membrane is about 22 μm, and the porosity is about 80%;

[0041] (3) Grind the carbon-supported Pt catalyst (wherein the Pt mass content is 40%), 10% CHF1000 resin and 5% polytetrafluoroethylene emulsion into ink, and spray it into the above-mentioned porous fiber membrane to obtain CHFM10125 with...

Embodiment 3

[0045] (1) In a closed stainless steel container, Nafion resin is added to dimethylacetamide solvent, and dissolved at 190°C to obtain a Nafion resin solution, wherein the concentration of Nafion resin is 65mg / L;

[0046] (2) With the Nafion112 film (EW=1100, film thickness about 51 μ m) of Dupont Company as the receiving screen, under the condition that the distance of 20 kilovolts and the spinneret to the receiving screen is 40 cm, the Nafion resin solution is electrospun Silk film formation to obtain Nafion112 with porous fiber membranes on both sides, wherein the porosity of the porous fiber membranes is about 85%;

[0047] (3) Grinding the carbon-supported Pt catalyst (wherein the Pt mass content is 40%), 5% Nafion resin and 5% polytetrafluoroethylene emulsion into ink, and spraying it into the above-mentioned porous fiber membrane to obtain a Nafion112 membrane with a catalytic layer , the Pt loading in the catalytic layer is about 0.2mg / cm 2 , the content of polytetraf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com