High-toughness bismaleimide resin material and preparation method thereof

A technology of maleimide resin and high toughness, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of increased viscosity of the resin system and deterioration of the resin system treatment process, and achieve Good interface adhesion, beneficial to material properties, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

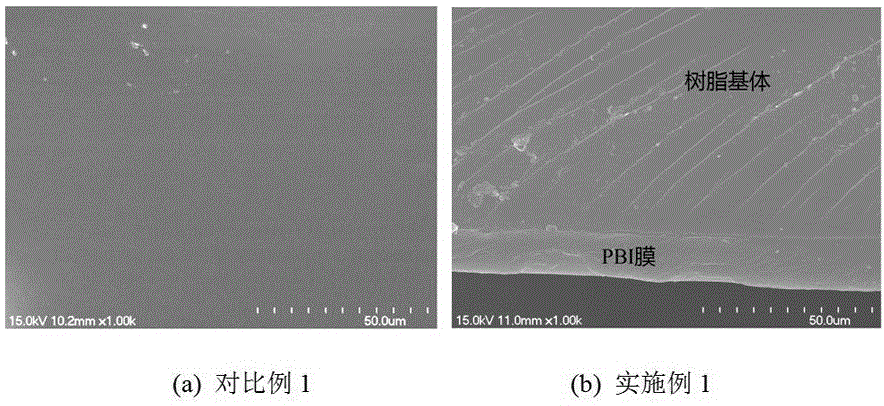

Embodiment 1

[0022] (a) Dissolve 0.42g of PBI in 10g of N,N-dimethylacetamide to obtain a PBI solution, divide the PBI solution into 2 equal parts and pour them into 2 horizontal flat molds with the same size, and then Heat at ℃ for 3 hours and at 100℃ for 1 hour to remove the solvent. After natural cooling, peel off the formed PBI film from the flat mold to obtain two PBI films with the same size. The thickness of the film is about 15 μm;

[0023] (b) Under stirring conditions, heat the mixture of 40g bismaleimidodiphenylmethane and 30g allyl bisphenol A at 140°C to a transparent solution, and keep the temperature for about 40min to obtain bismaleimide Aminodiphenylmethane / allyl bisphenol A prepolymer solution, pour it into a preheated flat mold (the length and width of the mold are the same as the length and width of the mold in (a)), vacuumize at 140°C About 30min, then naturally cool to room temperature, take out the prepolymer plate;

[0024] (c) Two pieces of PBI film are tiled resp...

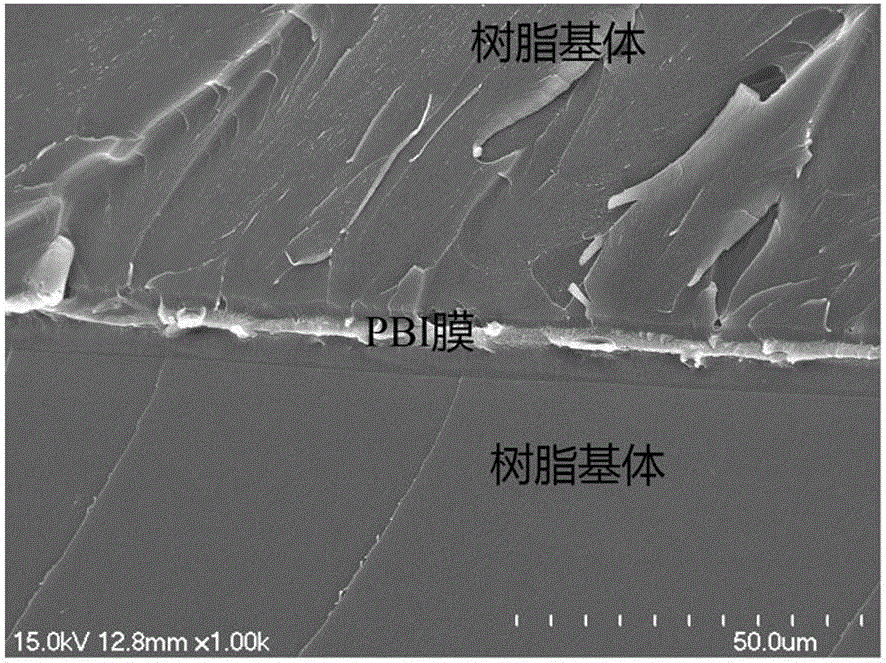

Embodiment 2

[0031](a) Dissolve 1g of PBI in 30g of N,N-dimethylformamide to obtain a PBI solution; divide the PBI solution into three equal parts and pour them into three horizontal flat molds of equal size, respectively, and heat at 60°C for 3h and heated at 100°C for 1 h to remove the solvent, and after natural cooling, the formed PBI film was peeled off from the flat mold to obtain 3 pieces of PBI film with a thickness of 25 μm;

[0032] (b) Under stirring conditions, heat the mixture of 40g bismaleimide diphenyl ether and 40g diallyl bisphenol S at 150°C to a transparent solution, and keep the temperature for about 40min to obtain bismaleimide Imide-based diphenyl ether / diallyl bisphenol S prepolymer solution is poured into two preheated flat molds of the same size (the length and width of the mold are the same as the length and width of the mold in (a) same), vacuumize at 150°C for about 30 minutes, then cool naturally to room temperature, and take out 2 prepolymer plates;

[0033] ...

Embodiment 3

[0040] (a) Dissolve 0.84g of PBI in 20g of N,N-dimethylacetamide to obtain a PBI solution; averagely divide the PBI solution into 4 equal parts and pour them into 4 horizontal flat molds of the same size, respectively, at 60°C Heating for 3 hours and 100°C for 1 hour to remove the solvent, and after natural cooling, peel the formed PBI film from the flat mold to obtain 4 pieces of PBI film with a film thickness of about 10 µm;

[0041] (b) Under stirring conditions, heat 40g of bismaleimidodiphenylmethane and 26g of allylphenol epoxy (bisphenol A diallyl diglycidyl ether) resin mixture to a transparent solution at 140°C , and then keep the temperature for about 40 minutes to obtain the bismaleimidodiphenylmethane / allylphenol epoxy resin prepolymer solution, which is divided into 3 equal parts and poured into 3 preheated flat molds respectively (The length and width of the mold are the same as the length and width of the mold in (a)), vacuumize at 140°C for about 30 minutes, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com