Crown reinforcement with shoulder ply

A technology of ply and reinforcement, applied in tire parts, reinforcement layers of pneumatic tires, tire edges, etc., can solve the problems of high cost and damage, and achieve the effect of improving the impact resistance of tire shoulders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

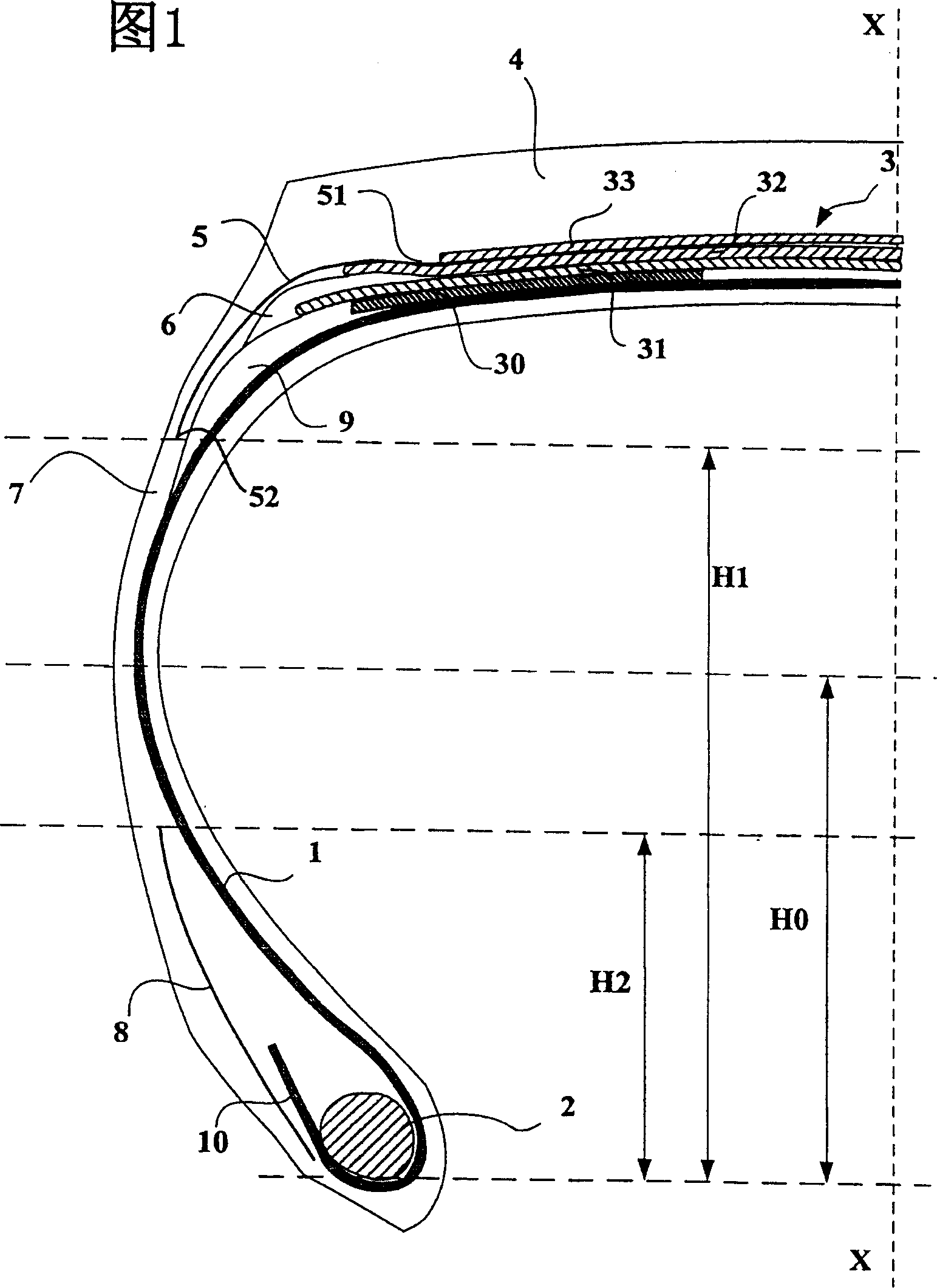

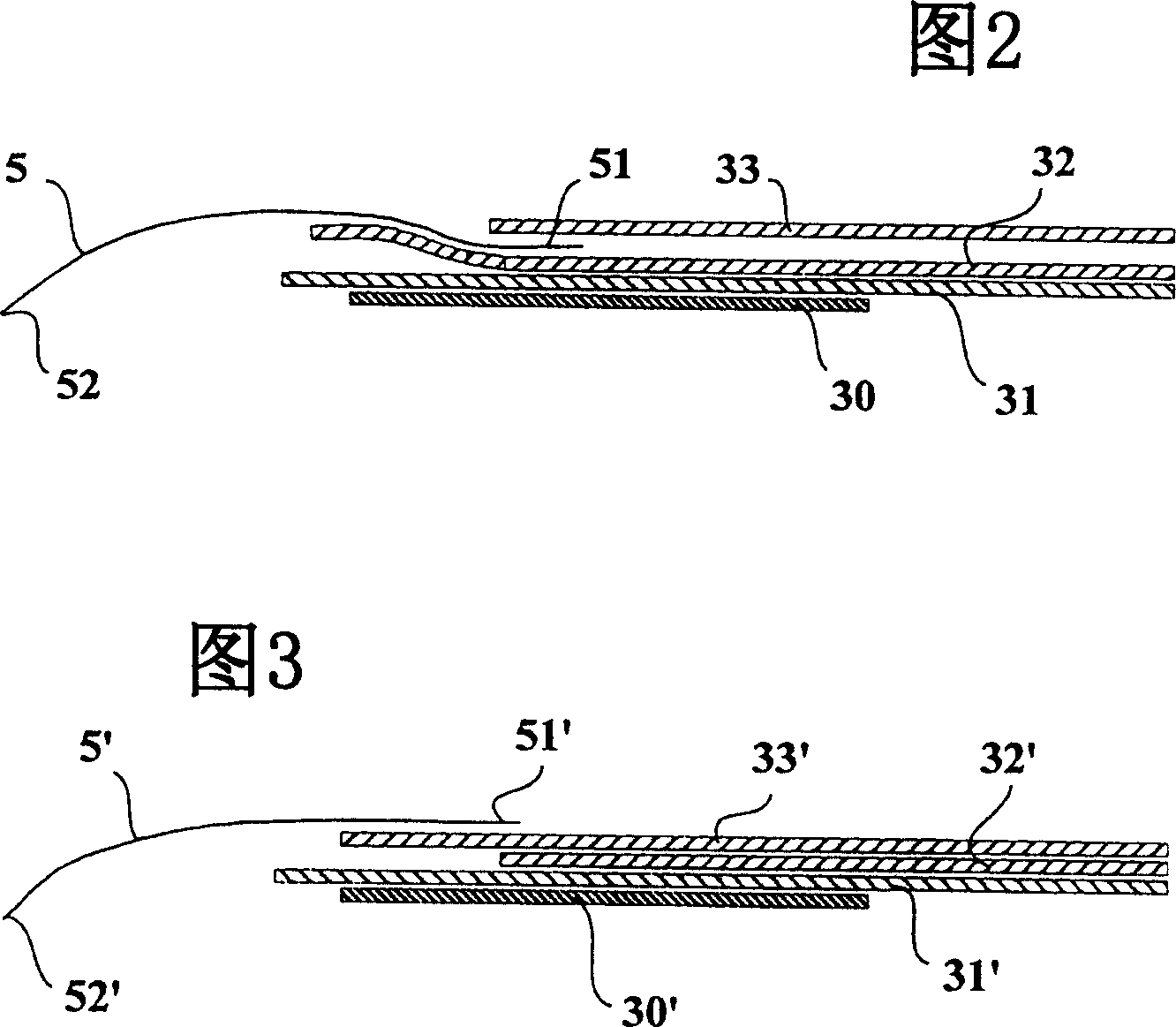

[0041] To simplify understanding, the figures are not shown to scale.

[0042] Figure 1 depicts a tire P of size 315 / 80R 22.5 having a radial carcass reinforcement with a single ply 1 of inextensible metal cores, that is to say the cores are The maximum elongation is 0.2% at 10% of the breaking load; in the case shown it is 27 x 23 cores (27 cores of 23 / 100 mm). The carcass reinforcement is fixed to the bead wire 2 in each bead, forming an inversion 10, the radially outer side of which is in turn surrounded by a crown reinforcement 3 covered by a tread 4 .

[0043] The crown reinforcement radially from inside to outside has:

[0044] - two crown half-plies 30, forming a triangular ply and consisting of 9 x 28 metal cores (9 cores of 28 / 100) at an angle α 0 orientation, in the case shown the α 0 is equal to 65°,

[0045] - a first crown working ply 31 radially covering this ply 30, consisting of 11×35 metal cores (11 cores 35 / 100) forming an angle α equal to 26° with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com