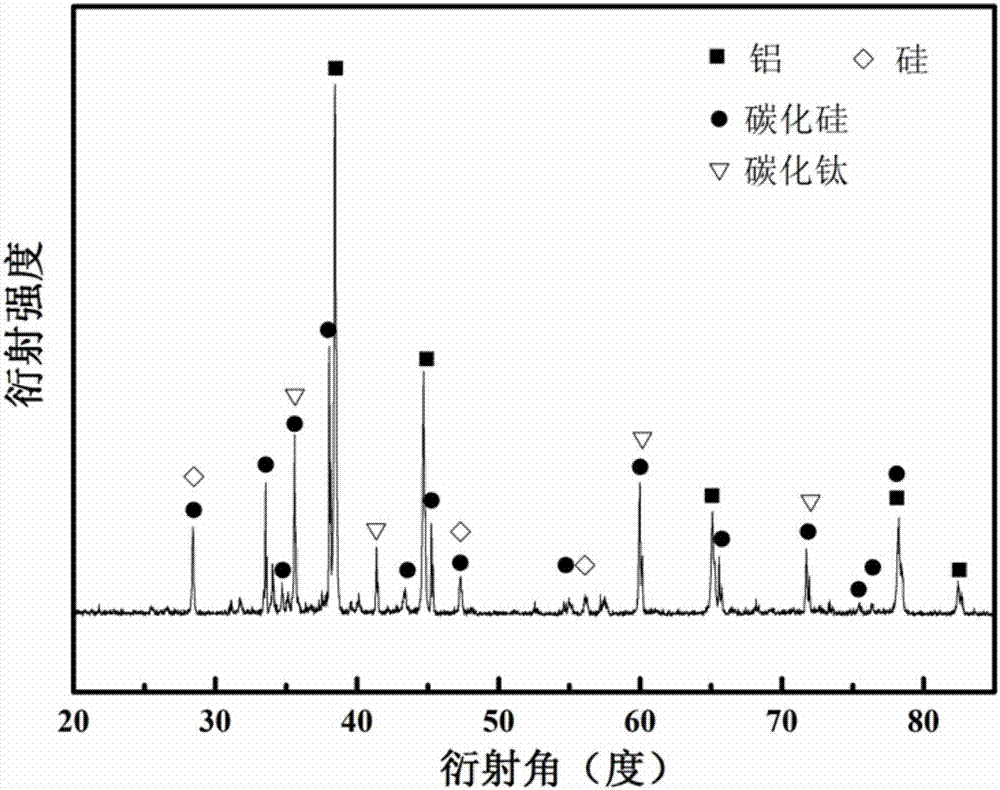

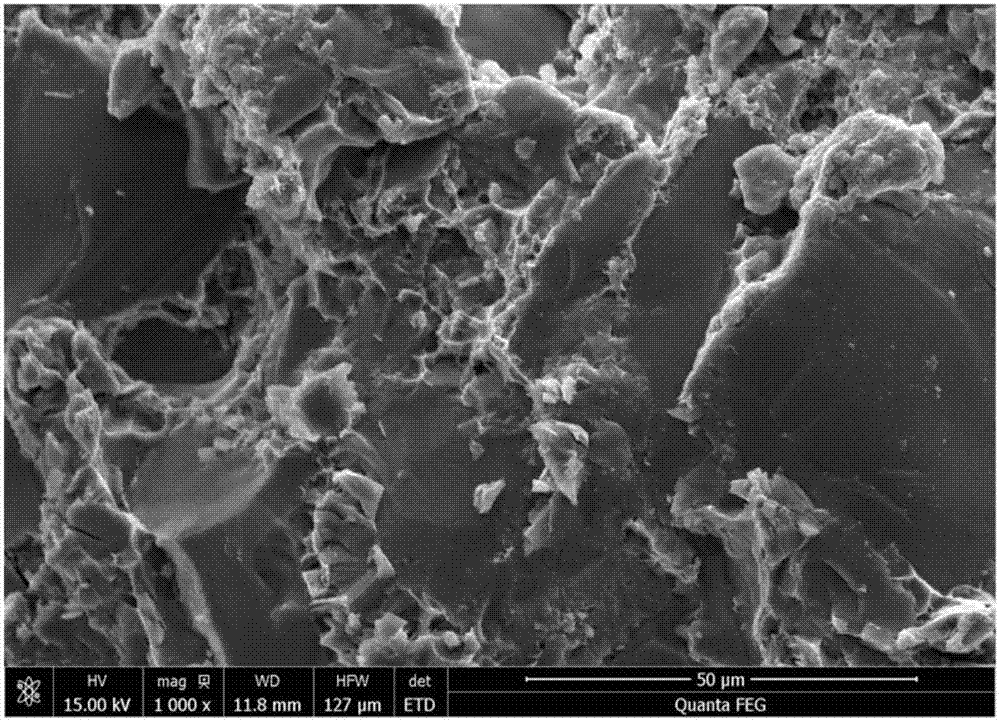

Preparation method for high-volume-fraction SiC reinforced Al-base composite material

A high volume fraction, composite material technology, applied in the field of preparation of SiC particle reinforced Al-based composite materials, can solve the problems of poor uniformity of structure, difficult production of complex parts, high equipment cost, etc., to achieve improved interface bonding performance, low production cost, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Oxidation treatment of SiC powder:

[0047] Put the SiC powder (particle sizes of 600 mesh, 300 mesh, and 150 mesh respectively, according to the mass ratio of 1:1:2) in a high-temperature electric furnace, and oxidize it at 1100 ° C for 2 hours to form a layer of dense SiO on the surface. 2 Floor.

[0048] 2. TiO2 2 Sol preparation:

[0049] Water and alcohol are configured into a mixed solution according to a mass ratio of 1:9, wherein the quality of water is 5g, adding glacial acetic acid (CH 3 COOH) to adjust the pH value to 2, wherein 12g of the mixed solution was taken, and butyl titanate (C 16 h 36 o 4 Ti) and the mixed solution were mixed at a mass ratio of 6:1, heated in a water bath (30°C) and stirred for 2 hours to obtain a transparent and stable TiO 2 Sol.

[0050] 3. SiC powder surface coating: TiO 2 The mixed sol and PVB were added to the oxidized SiC powder according to 10% of the mass of the added SiC powder, and mixed with a KNM type fast gri...

Embodiment 2

[0061] 1. Oxidation treatment of SiC powder:

[0062] Put the SiC powder (particle sizes of 600 mesh, 300 mesh, and 150 mesh respectively, according to the mass ratio of 1:1.2:2.4 ingredients) in a high-temperature electric furnace, and oxidize it at 1200 ° C for 3 hours to form a dense layer of SiO on the surface. 2 Floor.

[0063] 2. TiO2 2 Sol preparation:

[0064] Water and alcohol are configured into a mixed solution according to a mass ratio of 1:11, wherein the quality of water is 8g, adding glacial acetic acid (CH 3 COOH) to adjust the pH value to 4, wherein 12g of the mixed solution was taken, and butyl titanate (C 16 h 36 o 4 Ti) and the mixed solution were mixed at a mass ratio of 9:1, heated in a water bath (40°C) and stirred for 4 hours to obtain a transparent and stable TiO 2 Sol.

[0065] 3. SiC powder surface coating: TiO 2 The mixed sol and PVB were added to the oxidized SiC powder according to 15% of the mass of the added SiC powder, and mixed with a ...

Embodiment 3

[0076] 1. Oxidation treatment of SiC powder:

[0077] Put the SiC powder (particle sizes of 600 mesh, 300 mesh, and 150 mesh respectively, according to the mass ratio of 1:1.1:2) in a high-temperature electric furnace, and oxidize it at 1200 ° C for 2 hours to form a layer of dense SiO on the surface. 2 Floor.

[0078] 2. TiO2 2 Sol preparation:

[0079] Water and alcohol are configured into a mixed solution according to the mass fraction of 1:10, wherein the quality of water is 8g, adding glacial acetic acid (CH 3 COOH) to adjust the pH value to 4, wherein 12g of the mixed solution was taken, and butyl titanate (C 16 h 36 o 4 Ti) and the mixed solution were mixed at a ratio of 7:1, heated in a water bath (40°C) and stirred for 2 hours to obtain a transparent and stable TiO 2 Sol.

[0080] 3. SiC powder surface coating: TiO 2 The mixed sol and PVB were added to the oxidized SiC powder according to 12% of the mass of the added SiC powder, and mixed with a KNM type fast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com