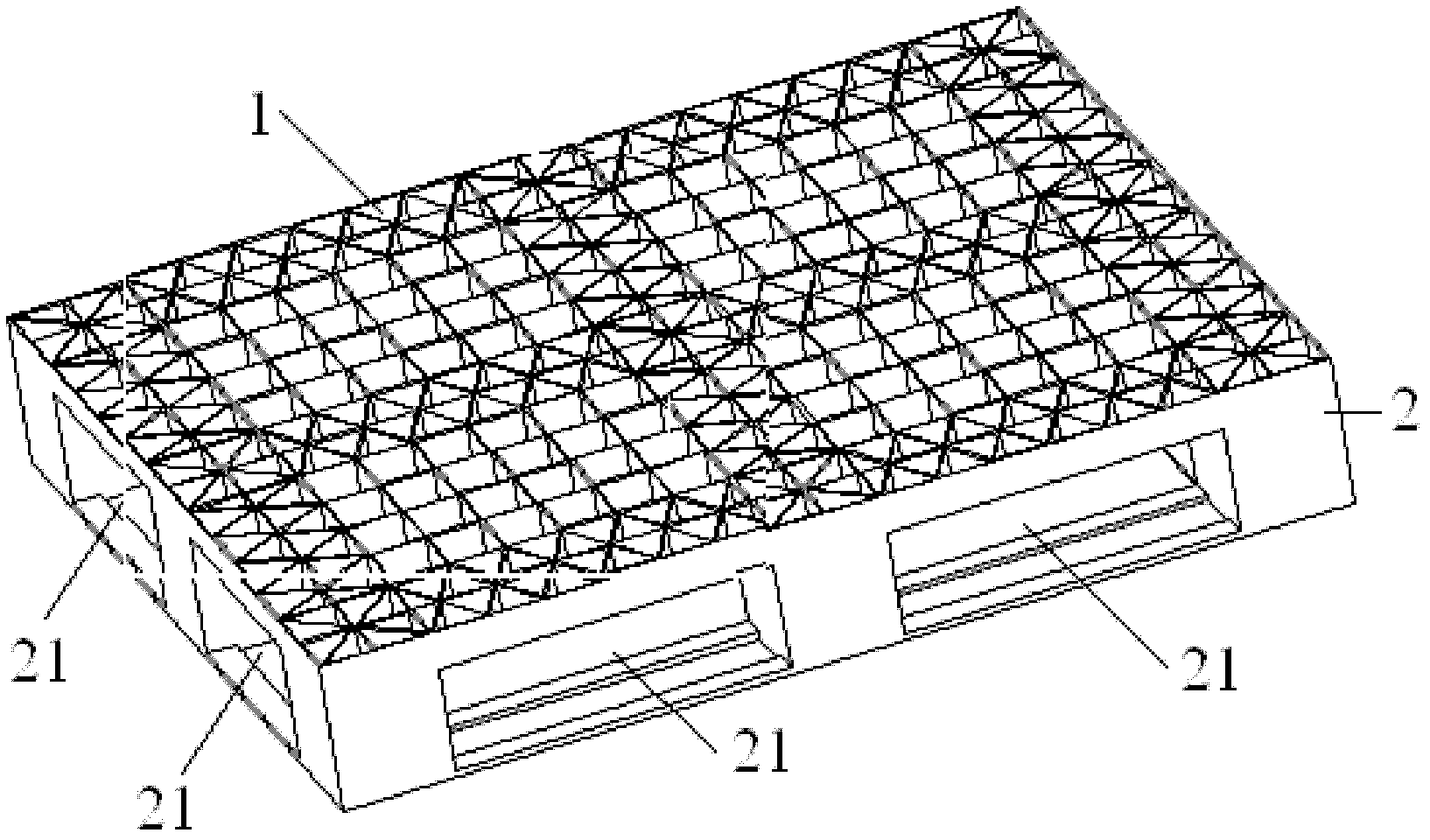

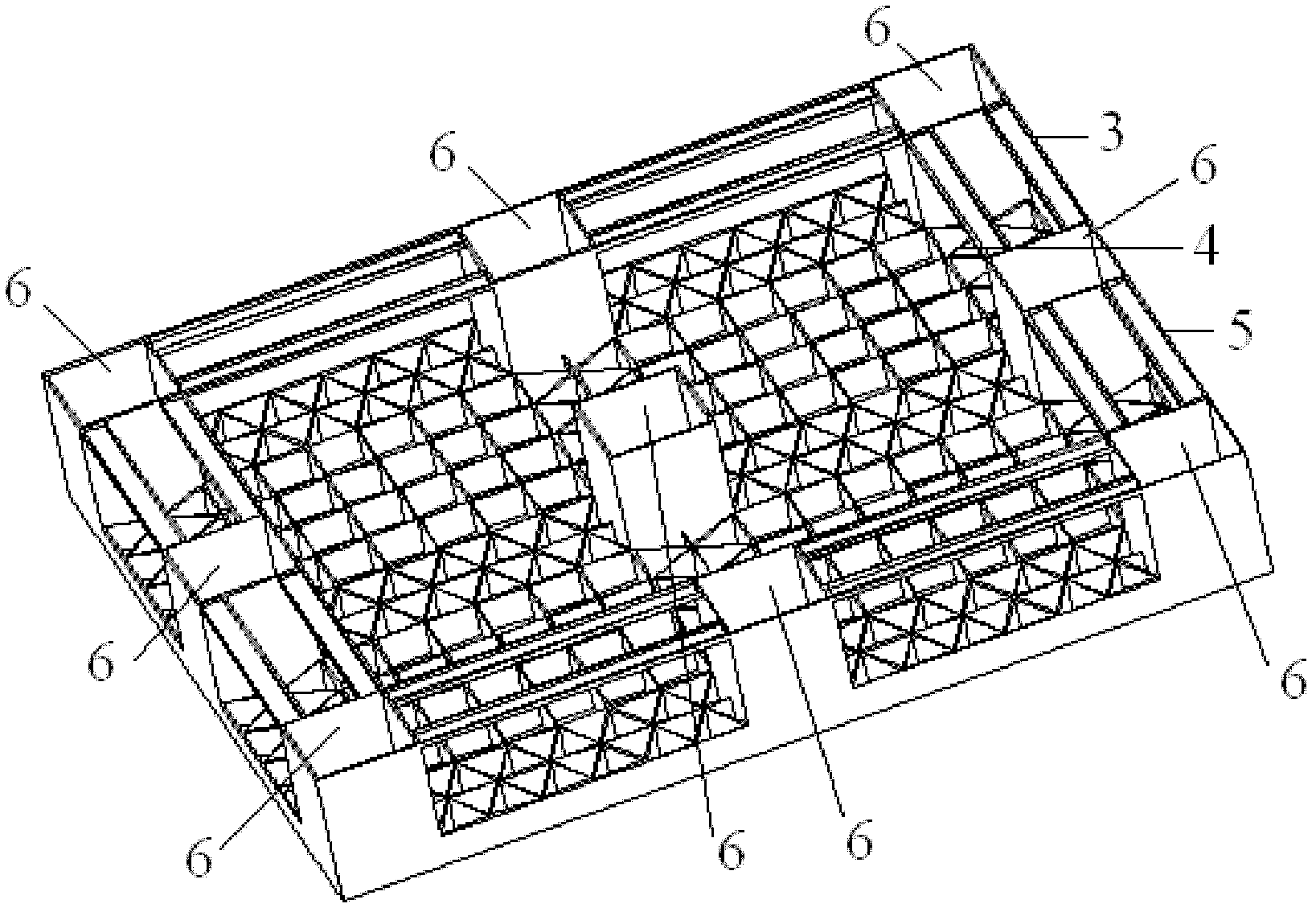

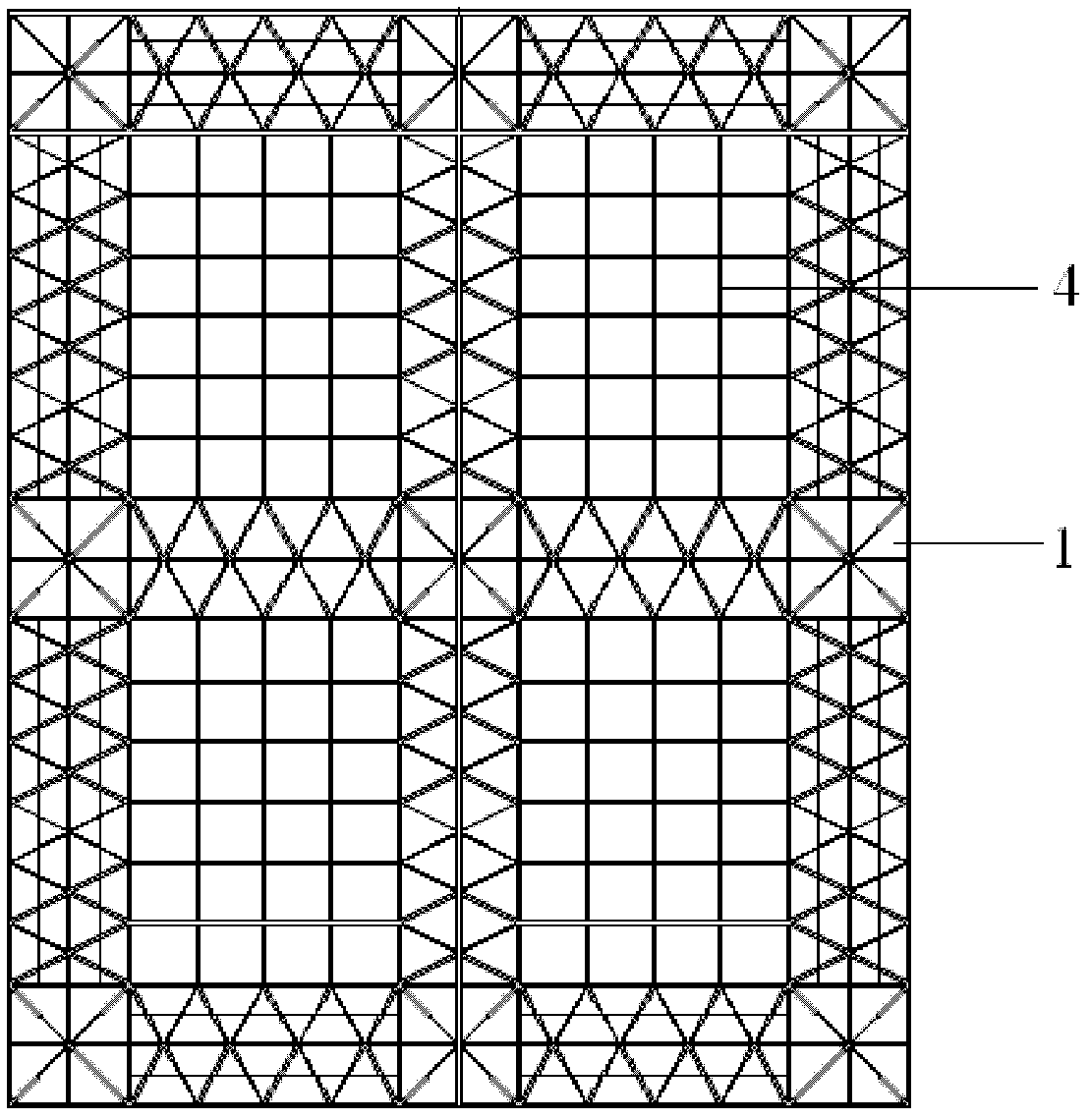

High-strength ultralight tray and preparation method thereof

An ultra-light, high-strength technology, used in containers, rigid containers, packaging, etc., can solve the problems of expensive mold investment, low market utilization, cumbersome processing technology, etc., to achieve beautiful appearance, easy for long-term storage, stacking long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 94.6 parts of polypropylene, 5 parts of talcum powder, 0.2 part of polypropylene grafted with maleic anhydride, 0.2 part of antioxidant 1010, 0.1 part of lubricant EBS and silane coupling agent KH-550 (γ-ammonia Propyltriethoxysilane) 0.1 part;

[0042] (2) above-mentioned raw material is sent in the twin-screw extruder by the feeder of precise measurement;

[0043] (3) 10 parts of alkali-free glass fibers are added separately from the feeding hole in the middle of the extruder, sheared and mixed at high speed by the twin-screw extruder, extruded by the head, drawn, air-cooled, pelletized, dried and Packaging to obtain a polyolefin reinforced material; the temperature of the twin-screw extruder is 190-240°C; the performance parameters of the material are shown in Table 1;

[0044] (4) Add the polyolefin reinforcement material prepared in the step into an injection molding machine, and perform injection molding to obtain a high-strength ultra-light pallet.

Embodiment 2

[0046](1) Weigh 89.2 parts of polypropylene, 10 parts of talcum powder, 0.2 part of polyethylene grafted with maleic anhydride, 0.2 part of antioxidant 1010, 0.2 part of lubricant EBS and silane coupling agent KH-570 (γ-( Methacryloxy) propyltrimethoxysilane) 0.4 part;

[0047] (2) above-mentioned mixture is sent in the twin-screw extruder by the feeder of precise metering;

[0048] (3) 5 parts of medium-alkali glass fiber are added separately from the feeding hole in the middle of the extruder, sheared and mixed at high speed by the twin-screw extruder, extruded by the head, drawn, air-cooled, pelletized, dried and Packaging to obtain a polyolefin reinforced material; the temperature of the twin-screw extruder is 190-240°C; the performance parameters of the material are shown in Table 1;

[0049] (4) Add the polyolefin reinforcement material prepared in the step into an injection molding machine, and perform injection molding to obtain a high-strength ultra-light pallet.

Embodiment 3

[0051] (1) Weigh 85.8 parts of polyethylene, 3 parts of talcum powder, 0.2 part of antioxidant 1010, 1 part of maleic anhydride grafted polypropylene, 0.01 part of lubricant N.N'-ethylene bisstearamide, coupling agent γ - 0.01 part of methacryloxypropyltrimethoxysilane and 10 parts of alkali-free chopped glass fiber;

[0052] (2) The above-mentioned mixture is sent into the twin-screw extruder by a feeder with precise metering, and glass fiber is added through the glass fiber inlet at the same time;

[0053] (3) After high-speed shearing and mixing by the twin-screw extruder, extruding from the machine head, drawing, air cooling, pelletizing, drying and packaging, polyolefin reinforced materials are obtained; the temperature of the twin-screw extruder is 190- 240°C; the performance parameters of this material are shown in Table 1;

[0054] (4) Add the polyolefin reinforcement material prepared in the step into an injection molding machine, and perform injection molding to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com