Titanium alloy gear and preparation method thereof

A titanium alloy and gear technology, applied in the field of titanium alloy gear and its preparation, can solve the problems of limiting gear wear resistance, power density and service life, low surface hardness and fatigue strength, complicated heat treatment process, etc. Heat treatment process, difficult processing, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

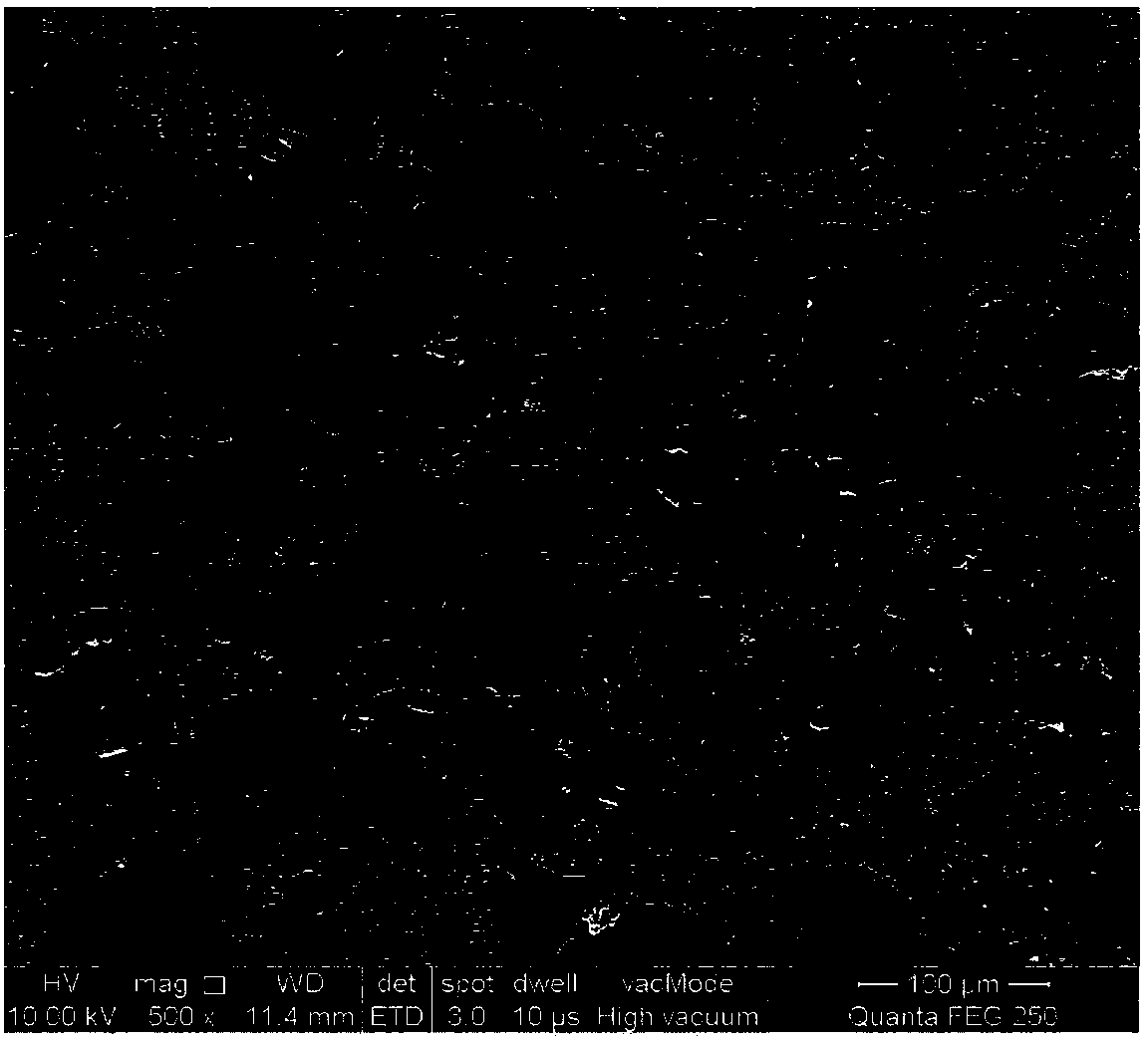

Image

Examples

Embodiment 1

[0040] 3D printing shape:

[0041] Using electron beam selective melting forming technology, under the conditions of working power 3000W, scanning speed 5300mm / s, spot diameter 200μm, and powder coating thickness 50μm, the TC21 titanium alloy powder was printed to form a gear matrix. Compared with the final formed gear, the gear matrix A thickness allowance of 1.6mm is reserved for the tooth thickness, which is used for subsequent laser cladding to form a surface hardened layer.

[0042] Hot isostatic pressing:

[0043] Put the above 3D printed titanium alloy gear base into a hot isostatic pressing furnace with a heating temperature of 950°C, a working pressure of 120 MPa, and a holding time of 60 minutes to obtain a gear body.

[0044] Laser cladding produces a hardfacing layer:

[0045] Spherical TiC powder, Ti powder and Ni powder are mixed in a ratio of 40:40:20, at a power of 2000W, a scanning speed of 3.5mm / s, a shielding gas flow rate of 2.5L / min, a beam diameter of 3...

Embodiment 2

[0049] 3D printing shape:

[0050] Using electron beam selective melting forming technology, under the conditions of working power 3000W, scanning speed 5300mm / s, spot diameter 200μm, and powder coating thickness 50μm, the TC21 titanium alloy powder was printed to form a gear matrix. Compared with the final formed gear, the gear matrix A thickness allowance of 1.6mm is reserved for the tooth thickness, which is used for subsequent laser cladding to form a surface hardened layer.

[0051] Hot isostatic pressing:

[0052] Put the above 3D printed titanium alloy gear base into a hot isostatic pressing furnace with a heating temperature of 950°C, a working pressure of 120 MPa, and a holding time of 60 minutes to obtain a gear body.

[0053] Laser cladding produces a hardfacing layer:

[0054] Spherical TiC powder, Ti powder and Ni powder are mixed in a ratio of 40:40:20, at a power of 2500W, a scanning speed of 2.5mm / s, a shielding gas flow rate of 2.5L / min, a beam diameter of 2...

Embodiment 3

[0058] Test the performance of the titanium alloy gear prepared by the embodiment of the present invention 1 and embodiment 2, the specific test method is:

[0059] The surface hardness is tested according to GB / T4340.1-2009 "Vickers Hardness Test of Metallic Materials Part 1: Test Method".

[0060] The wear performance is tested according to the standard GB / T 12444-2006 "Metallic Material Wear Test Method Test Ring-Test Block Sliding Wear Test".

[0061] The contact fatigue performance is tested according to the standard GB / T 14229-93 "Test Method for Gear Contact Fatigue Strength".

[0062] The test results are shown in Table 1, and Table 1 shows the performance test results of the titanium alloy gears prepared in Example 1 and Example 2 of the present invention.

[0063] Table 1 The performance testing results of the titanium alloy gears prepared in Example 1 and Example 2 of the present invention

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com