Strong-strength load bearing pallet

A high-strength, pallet-based technology, applied to rigid containers, containers, packaging, etc., can solve the problems of heavy weight and mechanical strength, and achieve the effect of large load-to-self-weight ratio, long stacking time, and convenient long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

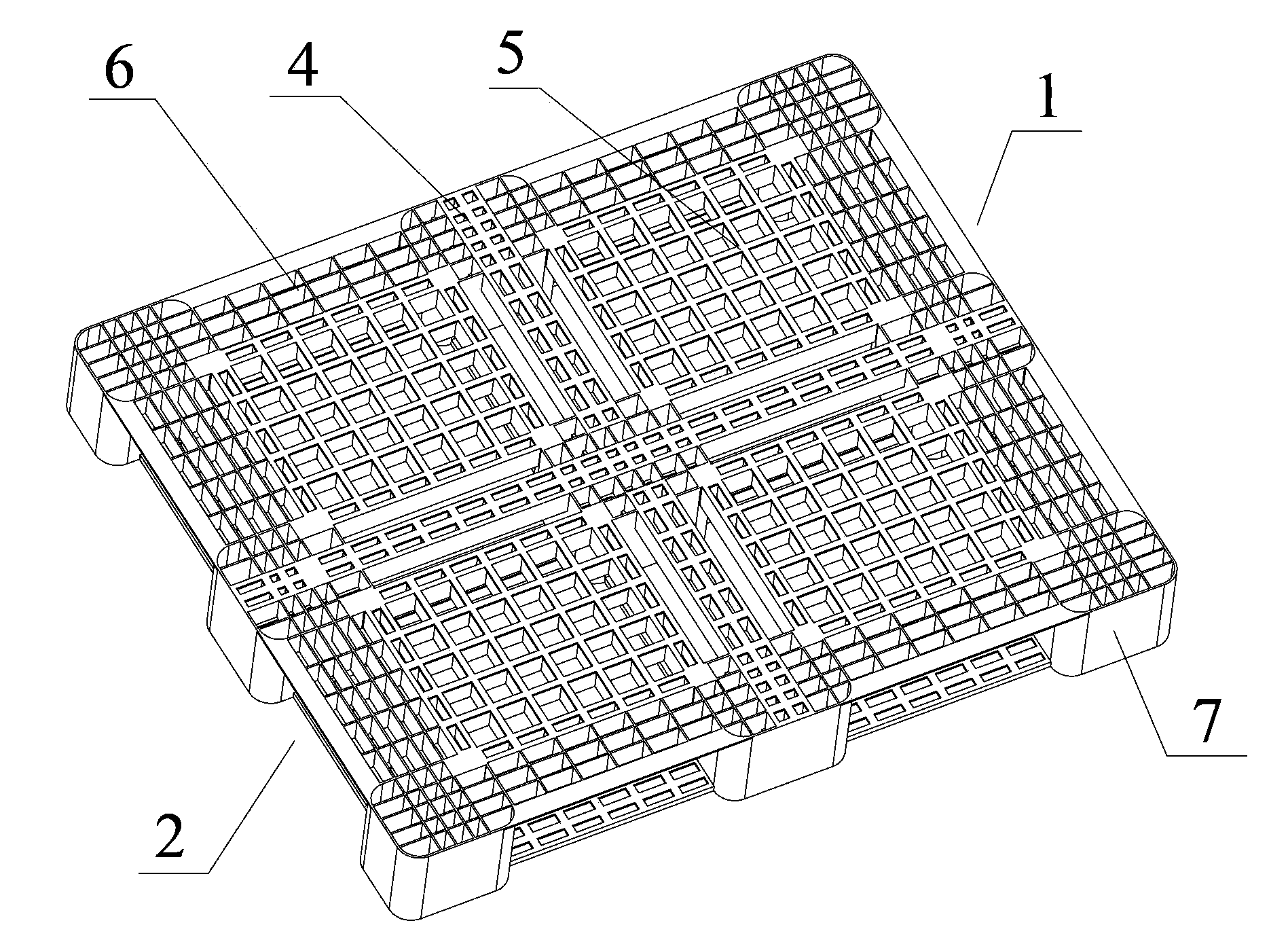

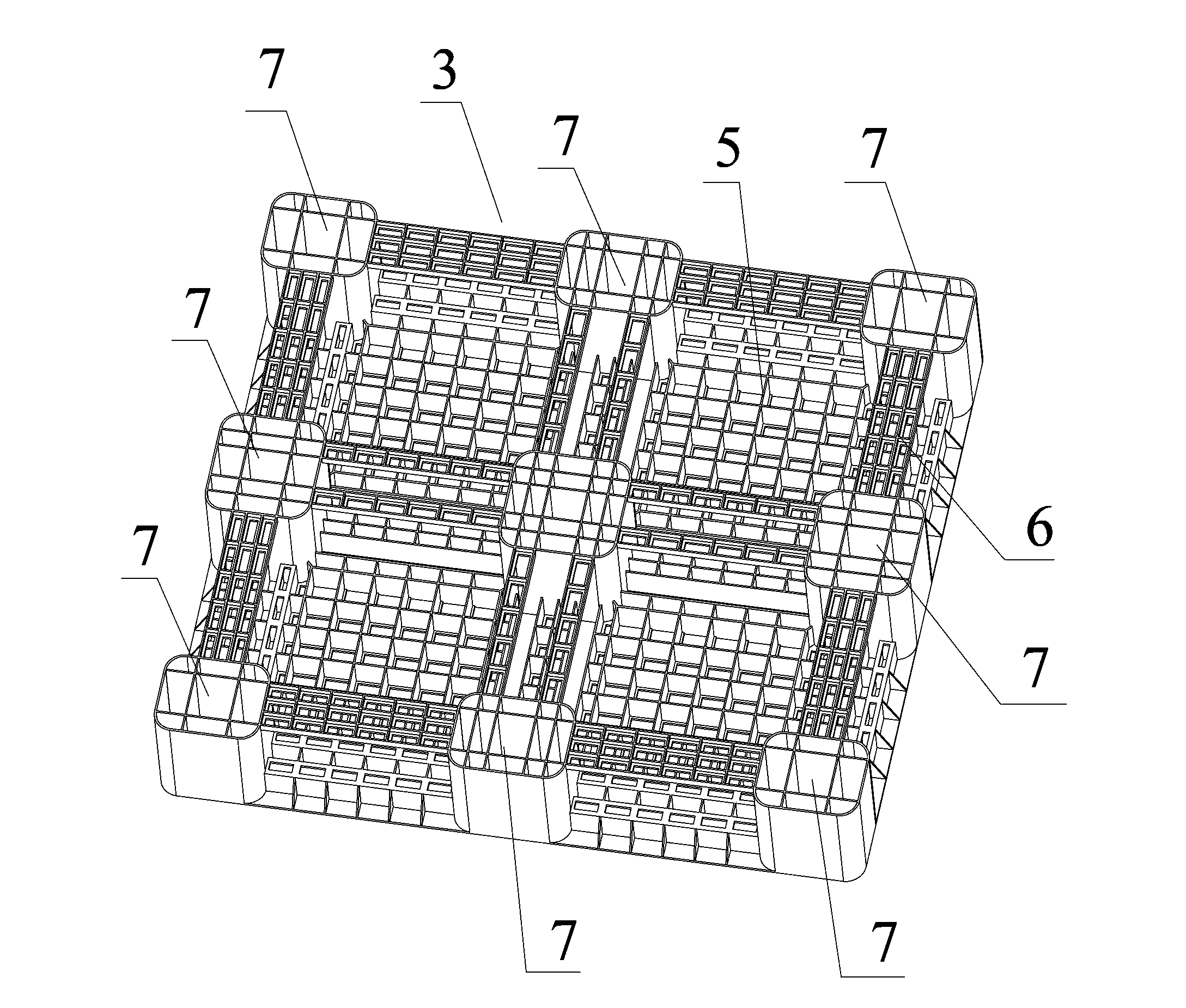

[0031] A high-strength load-bearing tray is injection molded from polypropylene PP and 30wt% glass fiber reinforced composite material, and its structure is as follows Figure 1-2 shown. The load-bearing tray is composed of an upper surface 1, a side surface 2 and a lower surface 3, wherein the upper surface 1 is composed of four horizontal grid-like structures, and between the grids is a hollow structure formed by grid ribs 4, and the grid ribs 4 are T-shaped structure, the upper end is the same width as the grid ribs, the height of the grid ribs 4 is 20mm, the width is 1.5mm, and the width of the hollow structure formed by the grid ribs 4 is 30mm.

[0032] A cross-shaped reinforcing rib 5 is arranged in the grid, and the width of the reinforcing rib 5 is 1.5 mm. The reinforcing rib 5 extends to the side 2 through the grid rib 4. The side 2 and the upper surface are connected at 90°, and the joint adopts a rounded corner transition, and the side is provided with a position ...

Embodiment 2

[0040] A high-strength load-bearing tray is injection molded from polypropylene PP and 45wt% glass fiber reinforced composite material, and its structure is as follows Figure 1-2 shown. The load-bearing tray is composed of an upper surface 1, a side surface 2 and a lower surface 3, wherein the upper surface 1 is composed of four horizontal grid-like structures, and between the grids is a hollow structure formed by grid ribs 4, and the grid ribs 4 are T-shaped structure, the upper end is 5 times the width of the grid ribs, the height of the grid ribs 4 is 50mm, the width is 5mm, and the width of the hollow structure formed by the grid ribs 4 is 70mm.

[0041] A cross-shaped reinforcing rib 5 is arranged in the grid, and the width of the reinforcing rib 5 is 5 mm. The reinforcing rib 5 extends to the side 2 through the grid rib 4. The side 2 and the upper surface are connected at 90°, and the joint adopts a rounded corner transition, and the side is provided with a position f...

Embodiment 3

[0048] A high-strength load-bearing pallet, the upper surface of which is composed of four horizontal diamond-shaped structures, and the rest of the structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com