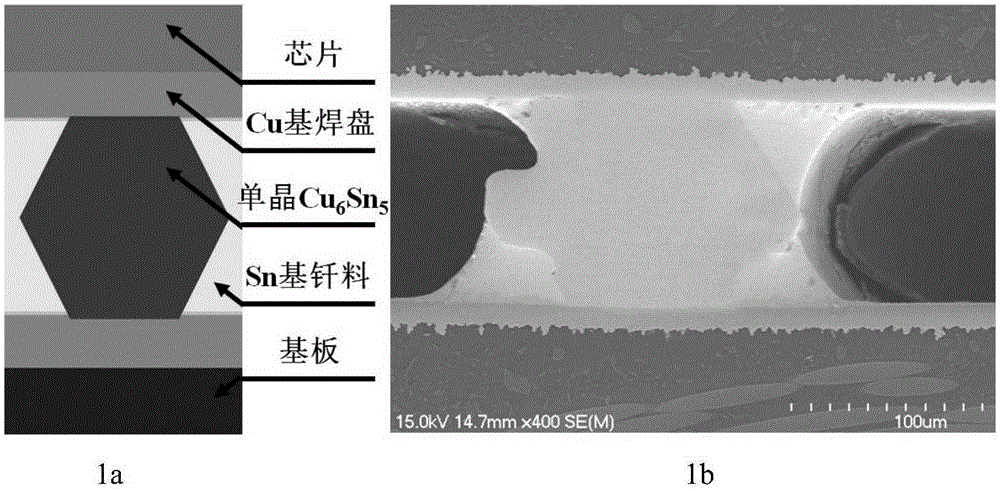

Directional interconnection method for Cu6Sn5-base single-crystal lead-free solder joints for high-temperature packaging

A lead-free solder joint and single crystal technology, applied in the field of materials, can solve problems that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

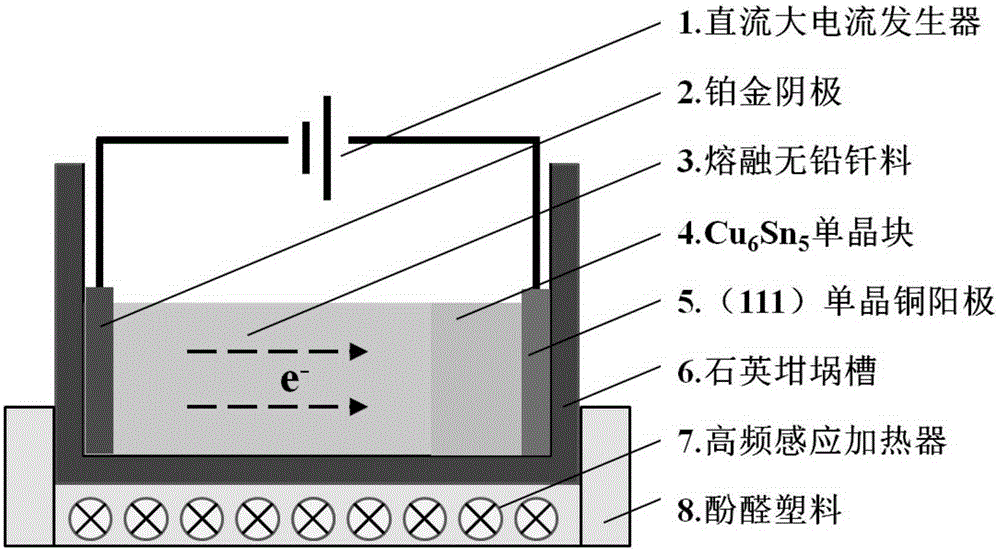

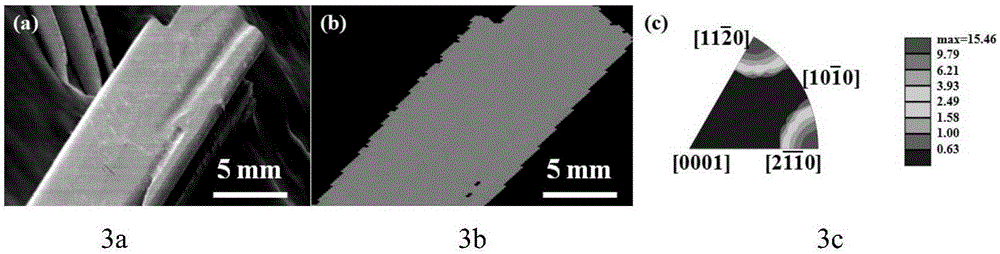

Embodiment 1

[0101] Embodiment 1 prepares Cu with a diameter of 100 μm 6 sn 5 base single crystal interconnect solder joints

[0102] 10×10×20mm 3 Platinum cathode with 10 x 10 x 20mm 3 The (111) single crystal Cu anode is put into 100×100×30mm 3 In the quartz crucible tank, the distance between the two stages is 100mm. The two poles are respectively connected to the DC high current generator with the copper wire covered with double-layer insulating nylon to form a conductive loop. Put 0.7kg of pure Sn solder into the crucible tank, turn on the high-frequency induction heating device, wherein the heating tube is 3cm away from the bottom of the crucible tank, and the induction heating frequency is 500KHz, and continue heating to completely melt the solder. At this time, the temperature of the molten solder is about 250°C, and the volume of the solder is about 100cm 3 , exactly 1 / 3 of the volume of the crucible can be filled. open N 2 Gas protection device to prevent oxidation of mol...

Embodiment 2

[0106] Embodiment 2 prepares Cu with a diameter of 50 μm 6 sn 5 base single crystal interconnect solder joints

[0107] 10×10×20mm 3 Platinum cathode with 10 x 10 x 20mm 3 The (111) single crystal Cu anode is put into 100×100×30mm 3 In the quartz crucible tank, the distance between the two stages is 50mm. The two poles are respectively connected to the DC high current generator with the copper wire covered with double-layer insulating nylon to form a conductive loop. Put 0.7kg of pure Sn solder into the crucible tank, turn on the high-frequency induction heating device, wherein the heating tube is 4cm away from the bottom of the crucible tank, and the induction heating frequency is 750KHz, and continue heating to completely melt the solder. At this time, the temperature of the molten solder is about 265°C, and the volume of the solder is about 100cm 3 , exactly 1 / 3 of the volume of the crucible can be filled. open N 2 Gas protection device to prevent oxidation of molte...

Embodiment 3

[0111] Example 3 Preparation of Cu with a diameter of 20 μm 6 sn 5 base single crystal interconnect solder joints

[0112] 10×10×20mm 3 Platinum cathode with 10 x 10 x 20mm 3 The (111) single crystal Cu anode is put into 100×100×30mm 3 In the quartz crucible tank, the distance between the two stages is 150mm. The two poles are respectively connected to the DC high current generator with the copper wire covered with double-layer insulating nylon to form a conductive loop. Put 0.7kg of pure Sn solder into the crucible tank, turn on the high-frequency induction heating device, wherein the heating tube is 5cm away from the bottom of the crucible tank, and the induction heating frequency is 1000KHz, and continue heating to completely melt the solder. At this time, the temperature of the molten solder is about 280°C, and the volume of the solder is about 100cm 3 , exactly 1 / 3 of the volume of the crucible can be filled. open N 2 Gas protection device to prevent oxidation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com