High-rigidity creep-resistant long-fiber-reinforced master batch for wood plastic products, and preparation and mold thereof

A technology for wood-plastic products and reinforced masterbatch, which is applied in the field of creep-resistant long-fiber reinforced masterbatch and its preparation, high rigidity for wood-plastic products, and impregnated molds, which can solve the complexity of brittle fracture, wood formation, and weight structure design Processing, safety hazards and other issues, to achieve the effect of reducing deformation, improving application performance and long-term use stability, and increasing flexural modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of long-fiber-reinforced masterbatch for high-rigidity, creep-resistant wood-plastic products

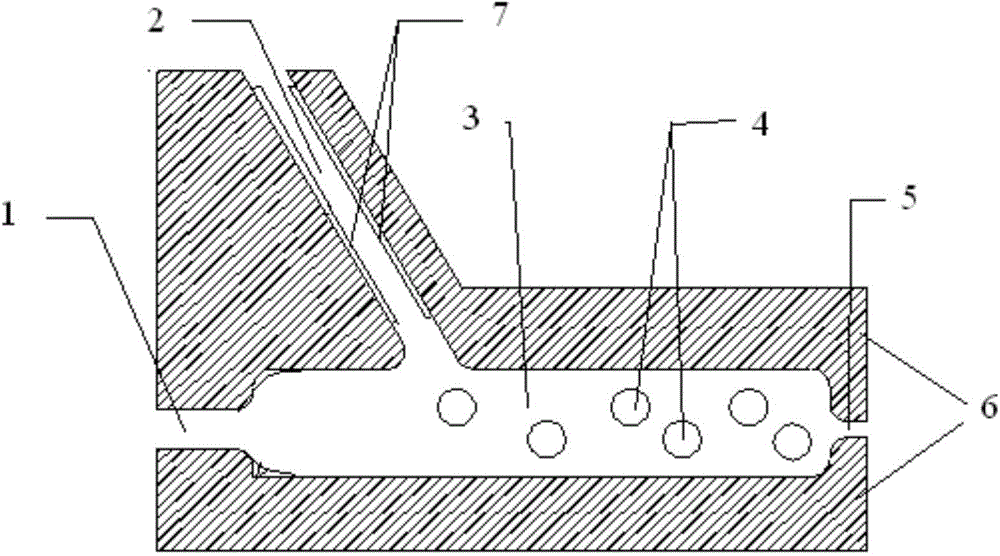

[0035] Such as figure 1 As shown, an impregnation mold includes a melt input flow channel 1; a fiber bundle inlet channel 2; a fiber bundle preheating sleeve 7; a melt impregnation chamber 3; a dot matrix tension roller 4; The melt impregnates the chamber cavity 6 .

[0036] a. Continuously introduce 30Kg glass fiber (362, Jushi Fiber Factory) into the mold cavity of the fiber impregnation mold after being preheated by the fiber bundle preheating sleeve 7, and the fiber bundle enters the melt impregnation chamber 3 through the fiber bundle inlet channel 2;

[0037] b. After premixing 65Kg polypropylene (V30G, Hainan Petrochemical), 0.5Kg KH-550, 5Kg polypropylene grafted maleic anhydride, 0.2Kg antioxidant 1010, and 0.1Kg antioxidant 168 in the mixer , added to the extruder to mix and melt into a melt, the melt enters the melt impregnation chamber 3 t...

Embodiment 2

[0039] Example 2: Preparation of long-fiber-reinforced masterbatch for high-rigidity, creep-resistant wood-plastic products

[0040] Such as figure 1 As shown, an impregnation mold includes a melt input flow channel 1; a fiber bundle inlet channel 2; a fiber bundle preheating sleeve 7; a melt impregnation chamber 3; a dot matrix tension roller 4; The melt impregnates the chamber cavity 6 .

[0041] a. Continuously introduce 30Kg glass fiber (362, Jushi Fiber Factory) into the mold cavity of the fiber impregnation mold after being preheated by the fiber bundle preheating sleeve 7, and the fiber bundle enters the melt impregnation chamber 3 through the fiber bundle inlet channel 2;

[0042] b. After premixing 65Kg nylon 6 (YH800, Yueyang Petrochemical), 0.5Kg KH-550, 5Kg POE-g-MAH, 0.2Kg antioxidant 1010, and 0.1Kg antioxidant 168 in the mixer, Add the extruder to mix and melt into a melt, and the melt enters the melt impregnation chamber 3 through the melt input channel 1 and...

Embodiment 3

[0044] Example 3: Preparation of long-fiber reinforced masterbatch for high-rigidity, creep-resistant wood-plastic products

[0045] Such as figure 1 As shown, an impregnation mold includes a melt input flow channel 1; a fiber bundle inlet channel 2; a fiber bundle preheating sleeve 7; a melt impregnation chamber 3; a dot matrix tension roller 4; The melt impregnates the chamber cavity 6 .

[0046] a. Continuously introduce 30Kg glass fiber (362, Jushi Fiber Factory) into the mold cavity of the fiber impregnation mold after being preheated by the fiber bundle preheating sleeve 7, and the fiber bundle enters the melt impregnation chamber 3 through the fiber bundle inlet channel 2;

[0047] b, the acrylic anhydride grafted ethylene elastomer of 65Kg of PBT (1100, Changchun, Taiwan), 0.5Kg of KH-550, 5Kg, 0.2Kg of antioxidant 1076, 0.1Kg of antioxidant 168 in the mixer. After mixing, add the extruder to mix and melt to form a melt, and the melt enters the melt impregnation cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com