High-flatness reinforced net for ion exchange membrane and application of high-flatness reinforced net

An ion-exchange membrane and reinforcing mesh technology, applied in the field of ion-exchange membranes, can solve the problem of unevenness in the effect of reinforcing mesh cloth surface, achieve the effect of improving appearance and performance, and solving unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

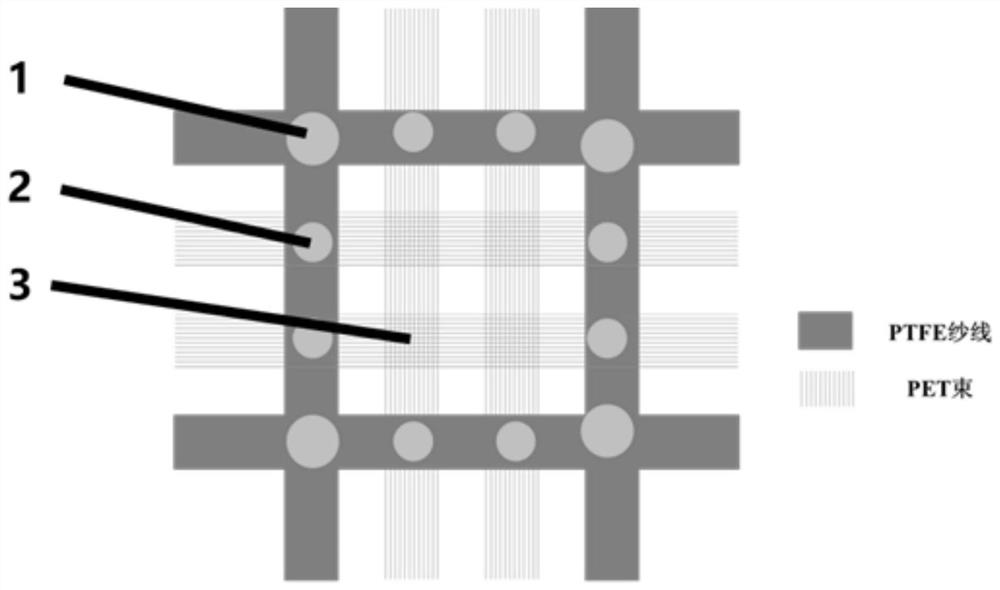

[0023] The highlands of the ion exchange membrane comprise a warp and weft yarns composed of polytetrafluoroethylene (PTFE) and polyester (PET) filaments. The tissue structure of the warp yarn and the weft yarn is a flat tissue, and the woven density of the polytetrafluoroethylene filament is 25 / inches, and the braided density of the polyester filament is 50 / inches. The polytetrafluoroethylene filament is monofilament, polyester is monofilament. The polytetrafluoroethylene filament diameter is 100 μm, and the polyester monofilament diameter is 45 μm, and the thickness value required after the reinforcing mesh has been required to be 80 μm, at this time, and Where T indicates that the thickness value required to enhance the net after rolling processing, the enhancement net is rolled by the rolling treatment, and the enhancement web flatness level is measured in accordance with the standard GB / T 13769 method. This enhancement network is applied to the molten polymer matrix f...

Embodiment 2

[0025] The high average reinforcing net for ion exchange membrane comprises a warp and weft yarns composed of polytetrafluoroethylene filaments and polyester filaments. The tissue structure of the warp yarn and the weft yarn is a tissue, and the woven density of the polytetrafluoroethylene filament is 25 / inches, and the braided density of the polyester filament is 200 / inches. The polytetrafluoroethylene filament is monofilament, and the polyester filament is monofilament. The polytetrafluoroethylene filament diameter is 100 μm, and the polyester monofilament diameter is 20 μm, and the thickness value as required after the net is removed from the rolling treatment, at this time, and Where T indicates that the thickness value required to enhance the net after rolling processing, the enhancement net is rolled by the rolling treatment, and the enhancement web flatness level is measured in accordance with the standard GB / T 13769 method. This enhancement network is applied to th...

Embodiment 3

[0027] The high average reinforcing net for ion exchange membrane comprises a warp and weft yarns composed of polytetrafluoroethylene filaments and polyester filaments. The tissue structure of the warp yarn and the weft yarn is a tissue, and the woven density of the polytetrafluoroethylene filament is 30 / inches, and the braided density of the polyester filament is 60 / inches. The polytetrafluoroethylene filament is a monofilament, and the polyester filament is a polyester. The polytetrafluoroethylene filament diameter is 50 μm, and the polyester diffuse diameter is 20 μm, and the thickness value required to reach after the net is removed from the rolling treatment. At this time, and Where T indicates that the thickness value required to enhance the net after rolling processing, the enhancement net is rolled by the rolling treatment, and the enhancement web flatness level is measured in accordance with the standard GB / T 13769 method. This enhancement network is applied to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Filament diameter | aaaaa | aaaaa |

| Thickness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com