Tightly packaged fiber, and dual-core indoor cable and processing method thereof

A technology of tightly wrapping optical fibers and fiber cores, applied in the direction of fiber mechanical structure, etc., can solve the problems that cannot be used alone, mechanical properties cannot be protected by optical fibers, and application limitations of tightly wrapped optical fibers, etc., to achieve the effects of low cost, light weight and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

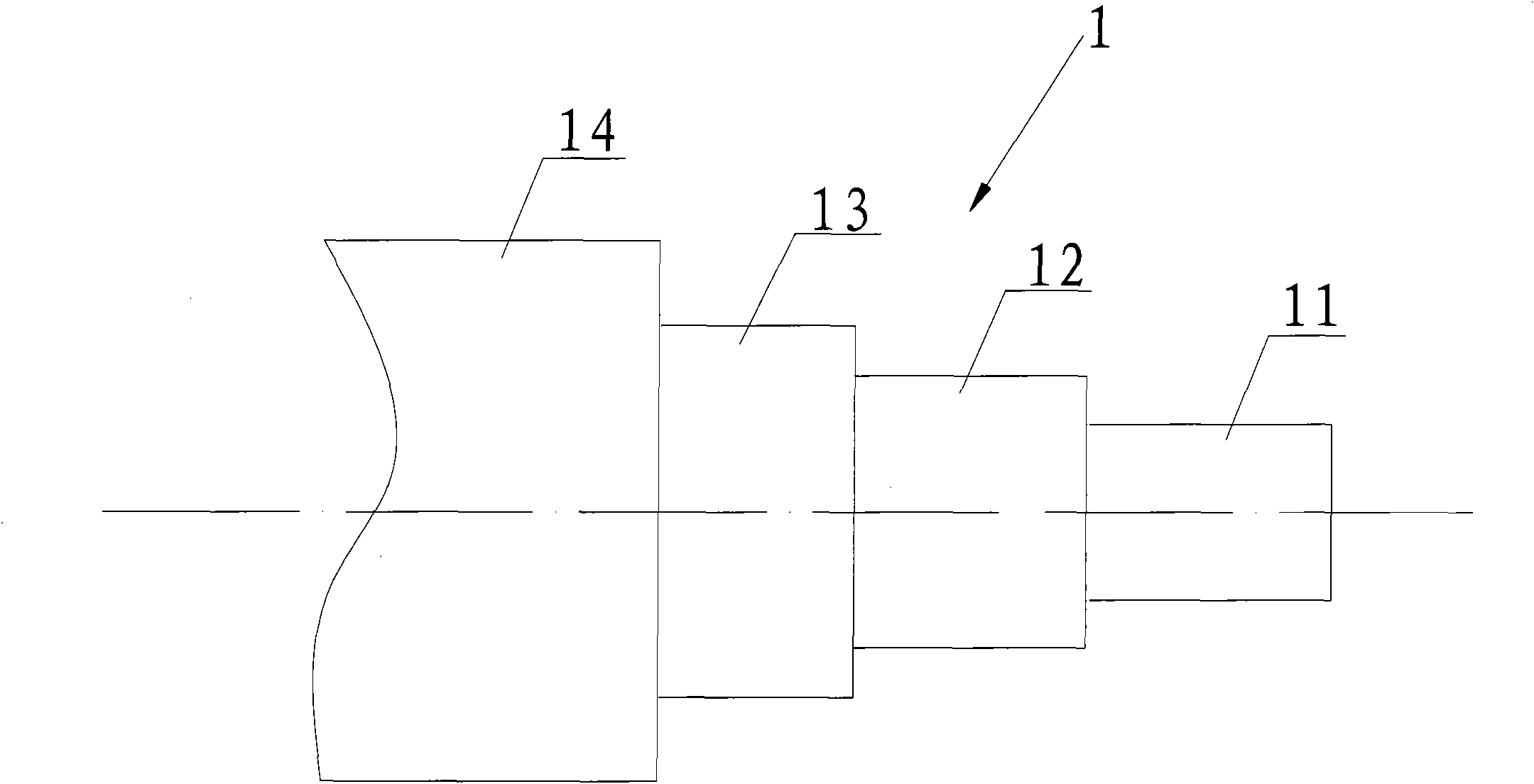

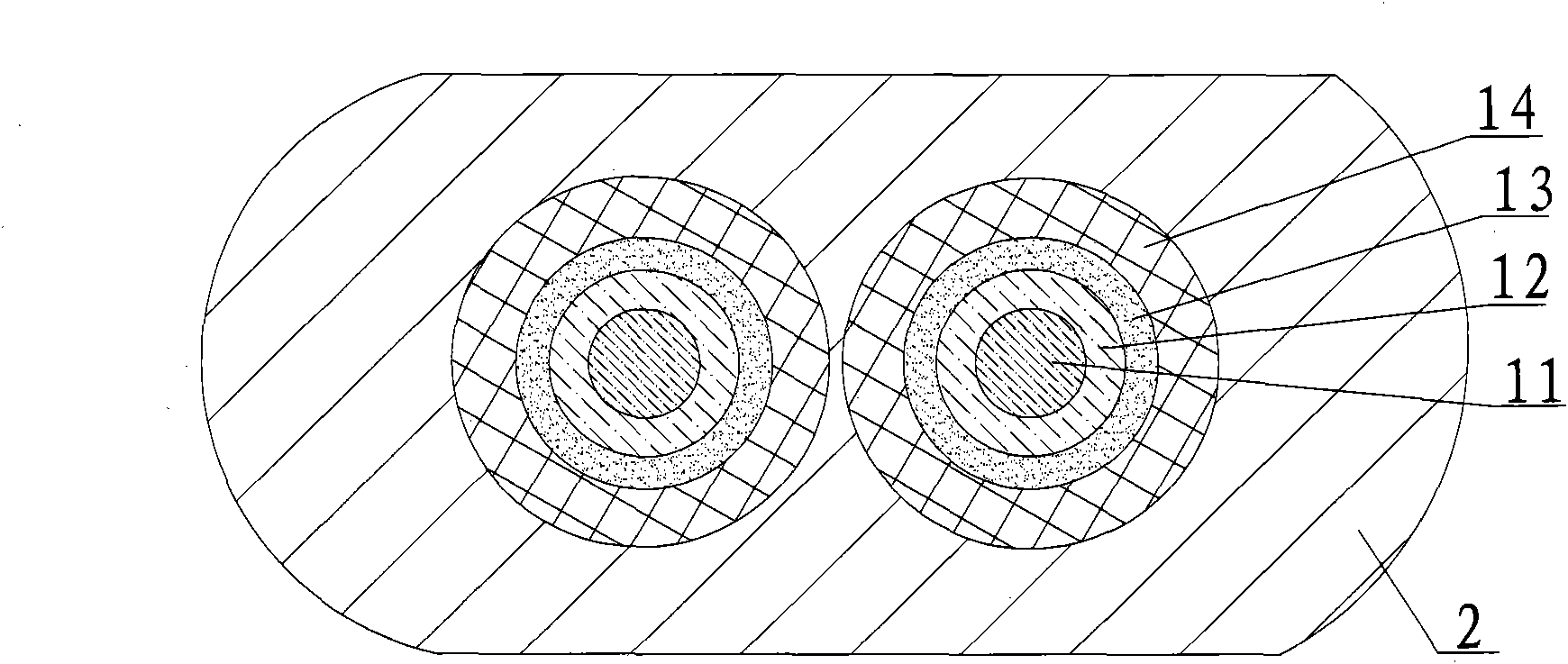

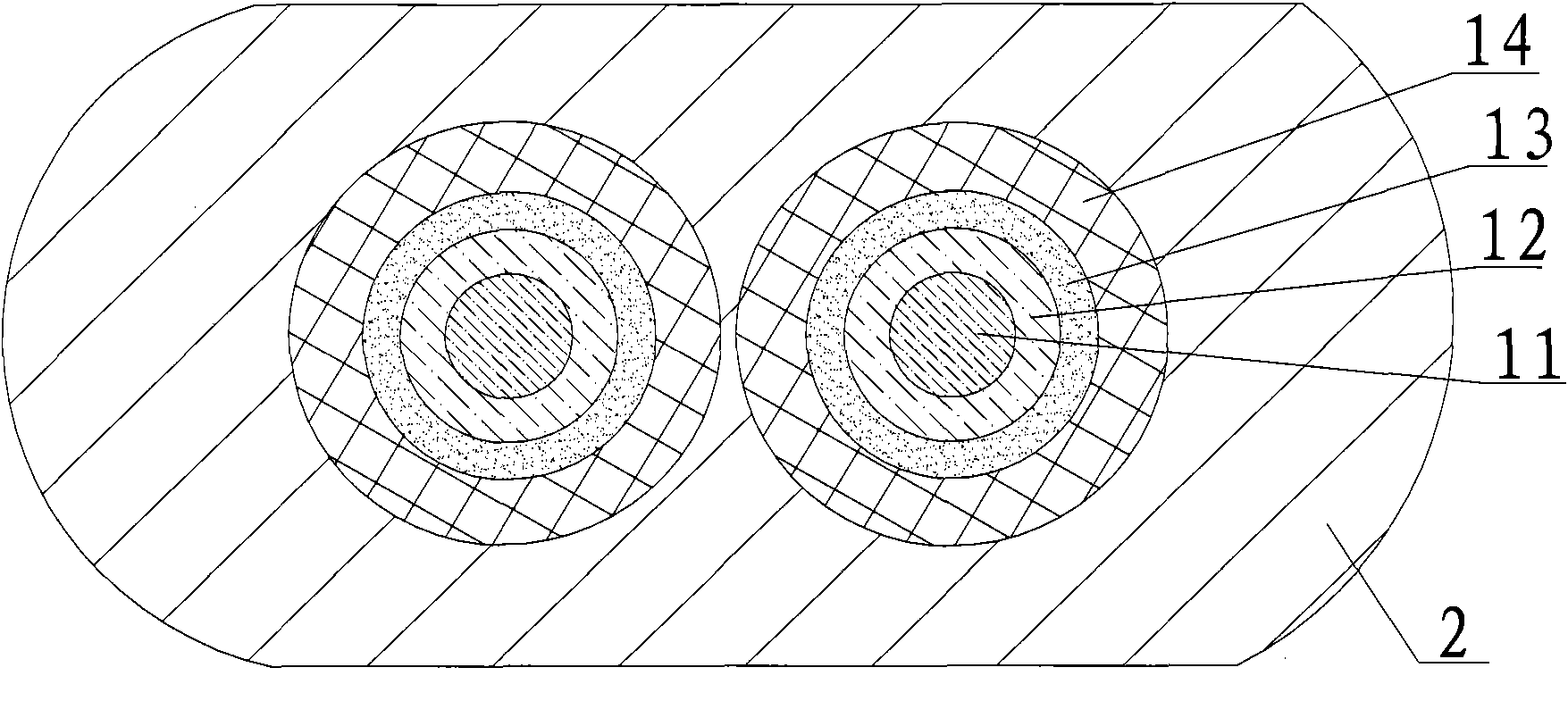

[0025] Such as figure 1 The shown tight-clad optical fiber consists of an optical fiber core 11 at the center, a cladding 12 coated on the periphery of the core 11, a primary coating 13 coated on the periphery of the cladding 12, and an extruded primary coating 13 outside the secondary coating layer 14 composition. Wherein, the fiber core 11 can be a single-mode fiber or a multimode fiber, both of which have an outer diameter of 125 μm, a single-mode fiber core diameter of 8.3 μm, and a multimode fiber core diameter of 50 or 62.5 μm . The primary coating layer 13 is coated with UV curable acrylic resin; the secondary coating layer 14 is made of polyvinyl fluoride.

[0026] The polyvinyl fluoride is also called ethylene-tetrafluoroethylene copolymer, commonly known as: F-40. Its English name is ETFE (ethylene-tetra-fluoro-ethylene). Polyvinyl fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com