Efficient automatic polishing processing method for molding surface of closed inner chamber, and dedicated equipment adopting method

An automatic polishing and processing method technology, which is applied in the field of mechanical processing, can solve problems such as unstable quality and low polishing efficiency, and achieve the effects of reducing processing stress, reducing processing deformation, and controlling part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The specifications of the vibration polishing machine equipment used are:

[0030]

[0031]

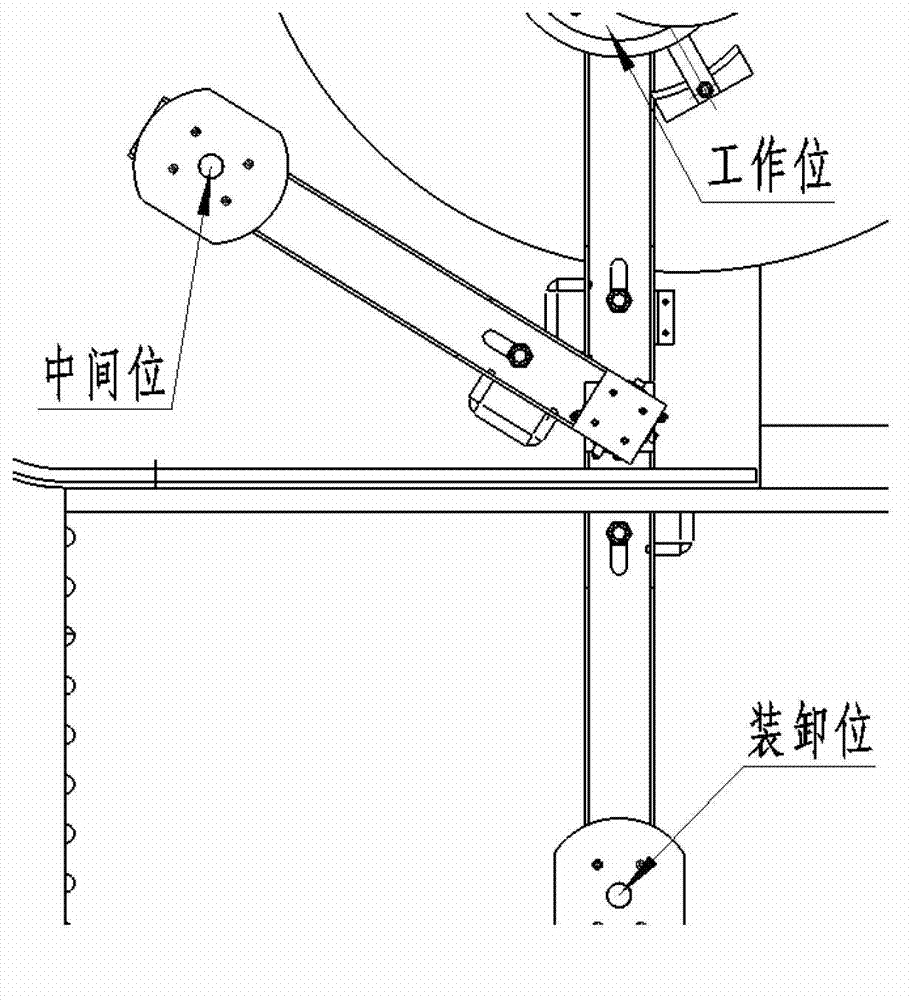

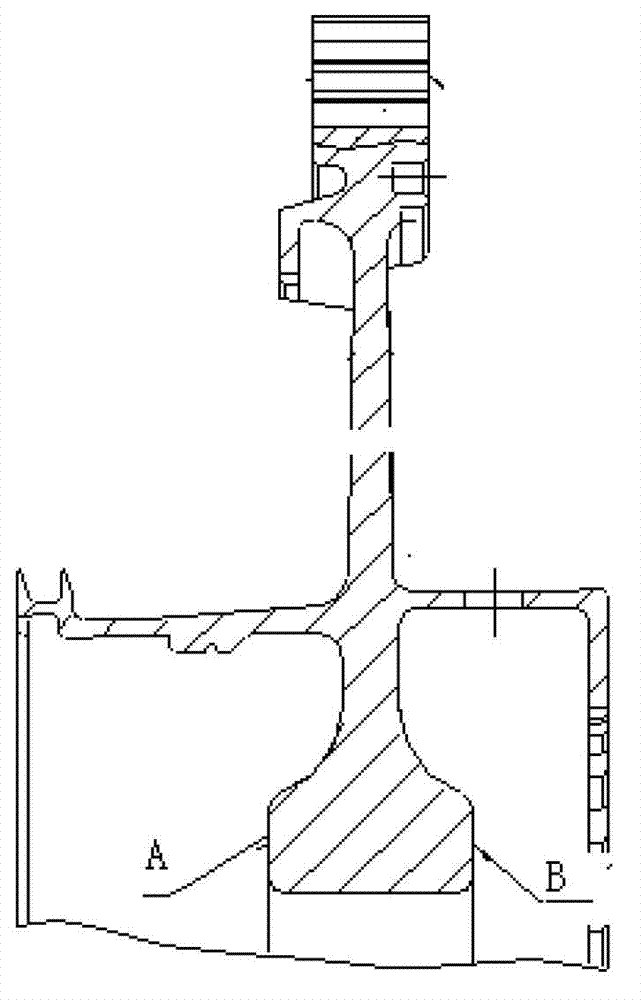

[0032] The structure of special vibrating finishing machine is as follows: Figure 4 As shown, the special vibrating finishing machine is based on the structure of the existing vibrating finishing machine, and a lifting system is added (such as Figure 4 Middle lifting track 3 and lifting mechanism 4) and swing system (such as Figure 4 middle swing system 6), that is, the lifting mechanism 4 is located on the top of the stand 2, and is connected to the lifting track 3 set up on one side of the stand 2; the swing system 6 is a gear box, and the clamp system 7 is connected to the headstock 5 through the swing system 6 .

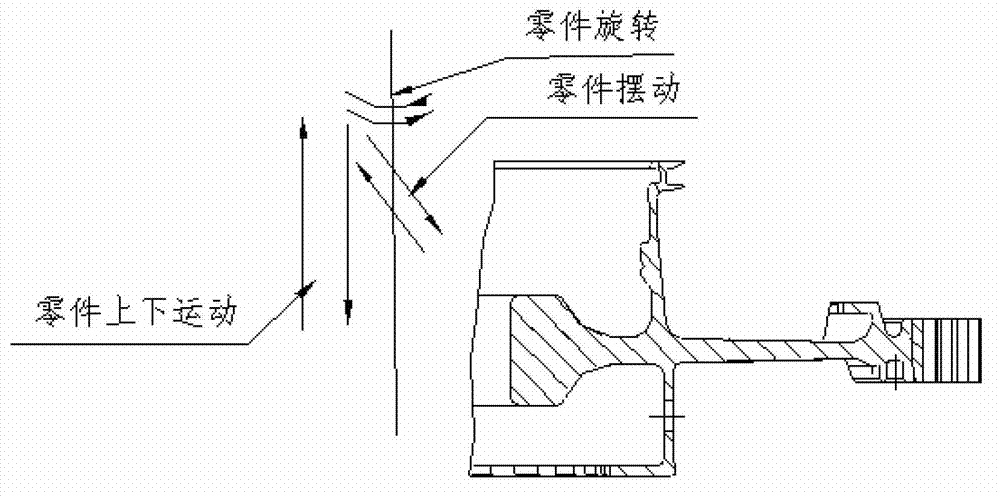

[0033] Adopt polishing processing method of the present invention:

[0034](1) Clamp the part on the main shaft of the machine tool through the fixture system 7, and select a suitable material box according to the outer dimension of the part to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com