High wear-resistant fishing net suitable for complex seabed fishing environment

A fishing net and environmental technology, applied in the direction of conjugated synthetic polymer artificial filament, etc., can solve the problems of general mechanical properties of polyethylene, reduce the service life of fishing gear, and the fishing net is not suitable for fishing operations, etc., to improve creep resistance and mechanical properties , extended service life and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

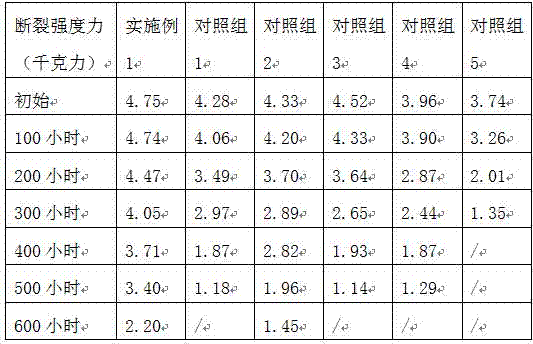

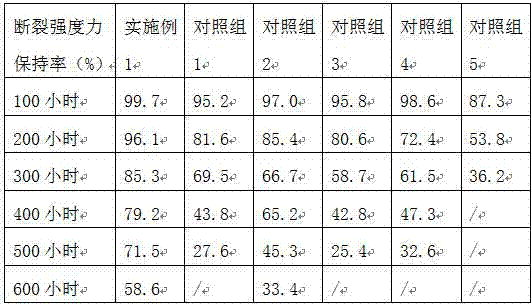

Examples

Embodiment 1

[0013] A high-wear-resistant fishing net suitable for complex seabed fishing environments, which is made of modified nano-silica with a surface hydroxyl number not higher than 0.4 / nm² and modified high-density polyethylene. The use of high-density polyethylene The amount is 75% of the total amount of raw materials for fishing nets.

[0014] Wherein, the preparation method of the modified nano-silica is as follows: adding nano-silica to an ethanol solution at a temperature of 45-50°C, preparing the silica into a 4.6% emulsion, and then adding an equivalent amount of silica 3-5% by weight of gluconolactone, after insulated and stirred for 10 minutes, add hexamethyldisilazane equivalent to 12.5% by weight of the emulsion, the pretreatment time is 20°C, the reaction temperature is 140°C, and the reaction time is 35 minutes; heat up to reflux temperature for reaction, after the reaction, the suspension is centrifuged and washed with ethanol for 3-4 times, and dried to constant we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com