Multi-phase functional ceramic honeycomb support and preparation method thereof

A technology of functional ceramics and supports, applied in the direction of ceramic products, chemical instruments and methods, catalyst carriers, etc., to achieve the effects of strong chemical corrosion resistance, refined grains, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

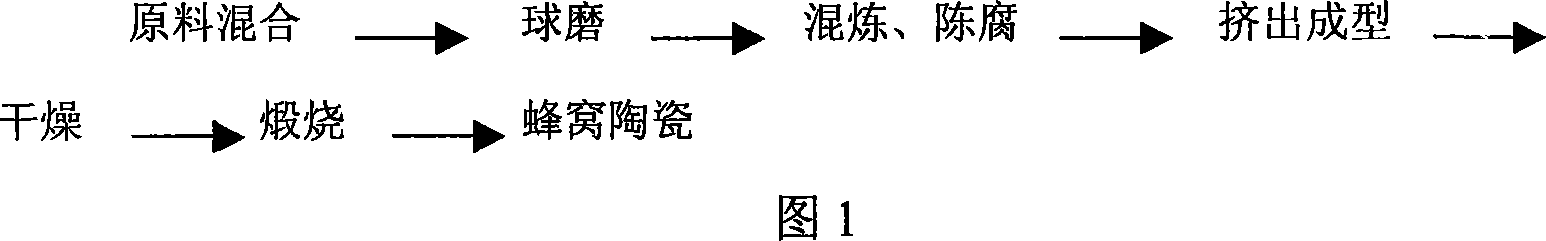

Method used

Image

Examples

Embodiment 1

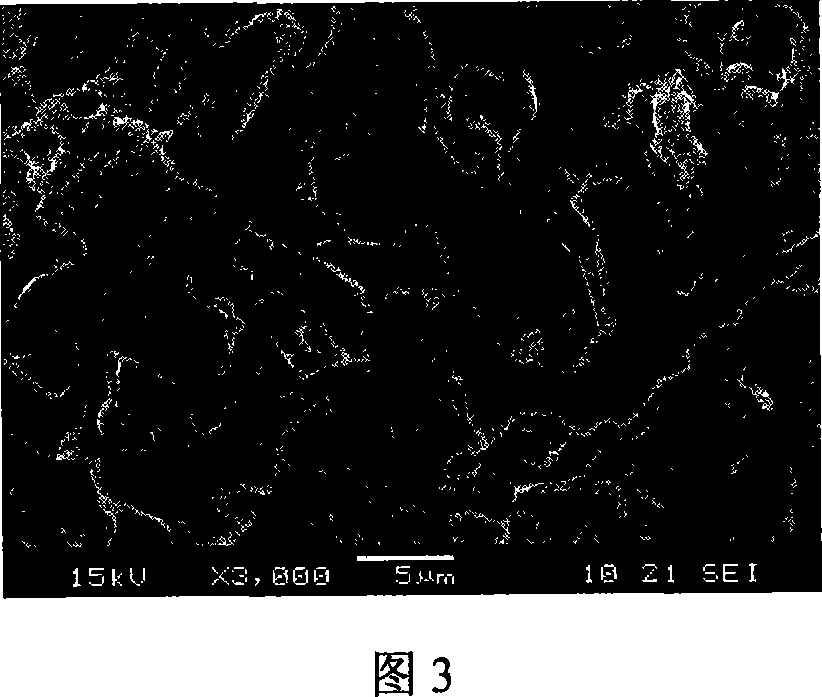

[0021] Mix 2400 grams of titanium dioxide, 1000 grams of alumina, 400 grams of silicon dioxide, 120 grams of magnesium oxide, and 40 grams of rare earth cerium oxide (the particle size of the mixed dry material is completely passed through a 60-mesh standard sieve), add 817 grams of water, 163.4 grams of tung oil, 408.45 grams of carboxymethyl cellulose were kneaded, extruded, dried in a drying oven at 110°C for 12 hours, and then heated to 1250°C for 3 hours to obtain the product. The product picture is shown in Figure 2, and its microscopic appearance is shown in Figure 3.

Embodiment 2

[0023] After mixing 2200 grams of titanium dioxide, 1200 grams of alumina, 400 grams of silicon dioxide, 40 grams of magnesium oxide, and 40 grams of rare earth erbium oxide (the particle size of the mixed dry material completely passes through a 60-mesh standard sieve), add 817 grams of water and 163.4 grams of wax The emulsion and 408.45 grams of polyvinyl alcohol were mixed, extruded, dried in a drying oven at 110°C for 12 hours, and then heated to 1300°C for 2 hours to obtain the product.

Embodiment 3

[0025] Mix 2600 grams of titanium dioxide, 800 grams of alumina, 480 grams of silicon dioxide, 200 grams of magnesium oxide, 40 grams of rare earth cerium oxide, and 40 grams of rare earth erbium oxide (the particle size of the mixed dry material is completely passed through a 60-mesh standard sieve), and add 817 grams of Water, 163.4 grams of tung oil, and 408.45 grams of carboxypolyvinyl alcohol were mixed, extruded, dried in a drying oven at 120°C for 12 hours, and then heated to 1280°C for 3 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com