Preparation method of specific composite filter material for coal-fired power plant electric bag integration project

A technology of coal-fired power plants and composite filter materials, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of unreachable service life, unfavorable wide-scale promotion, and high price, so as to improve service life, Improve the cleaning ability, strong and non-attenuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

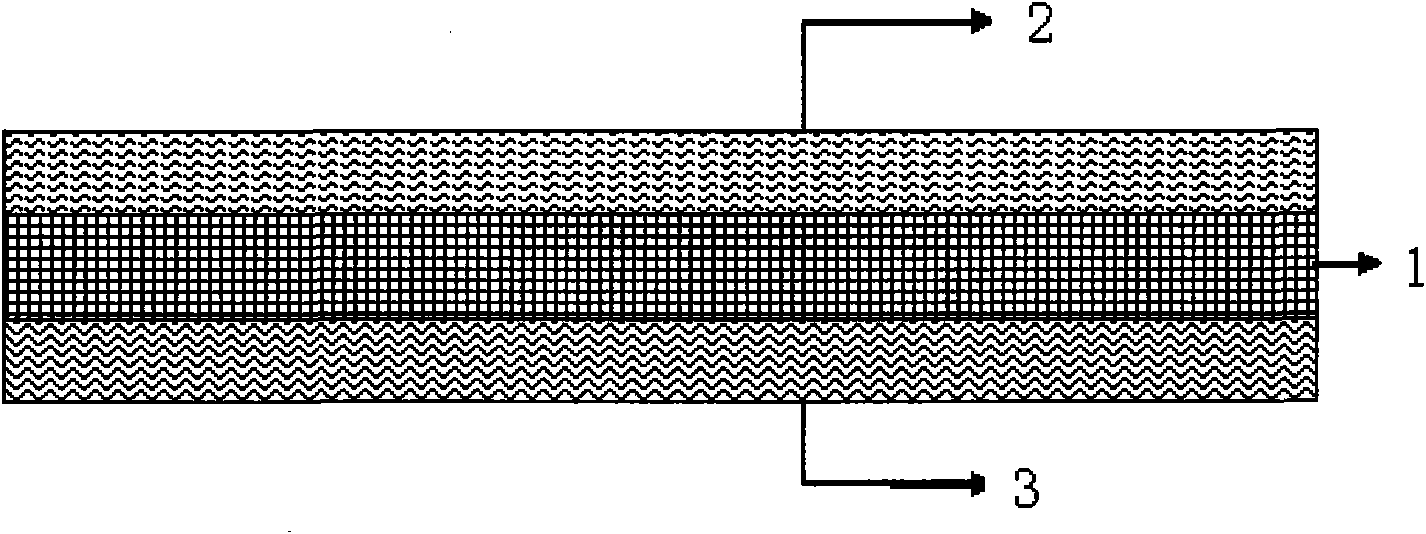

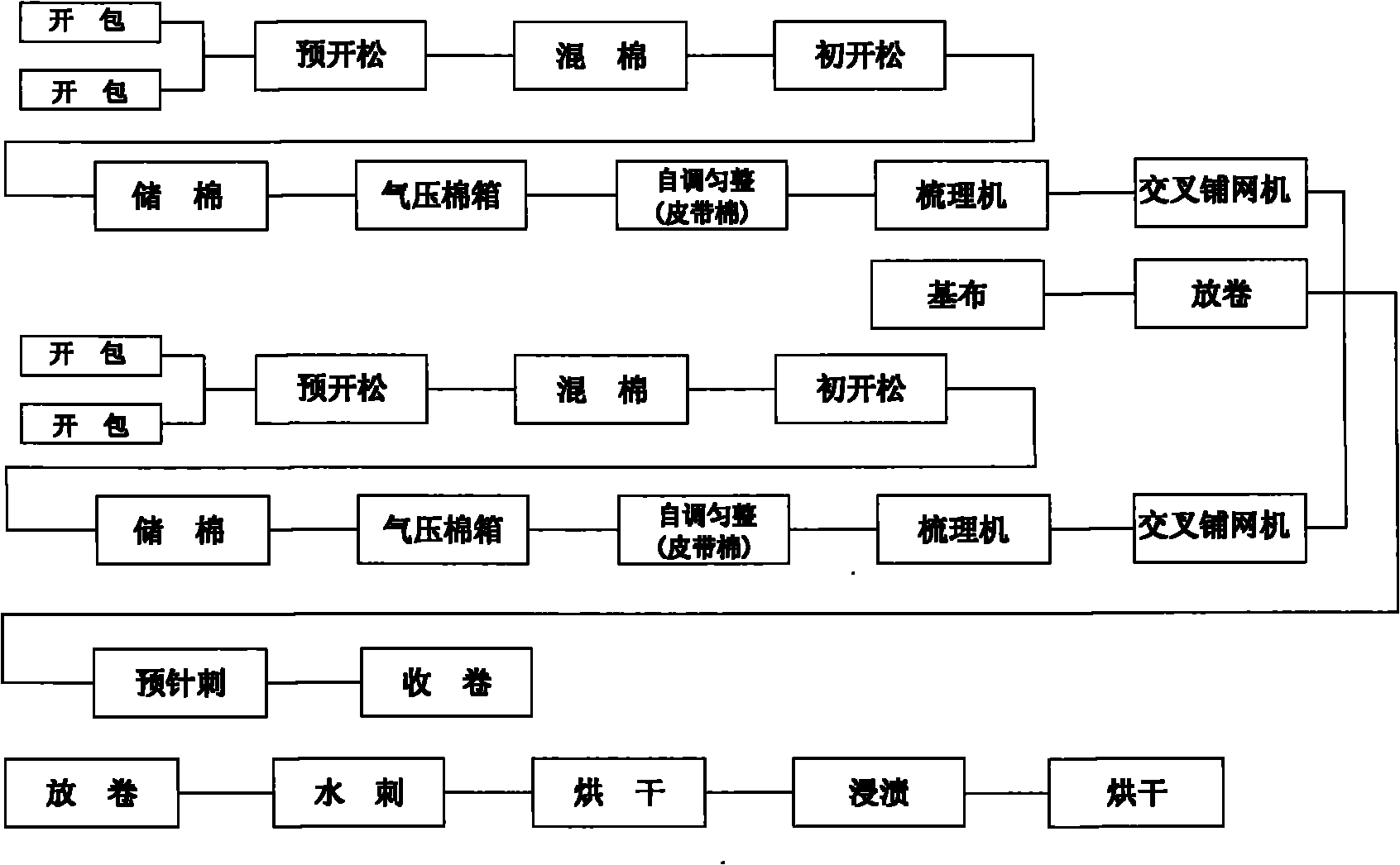

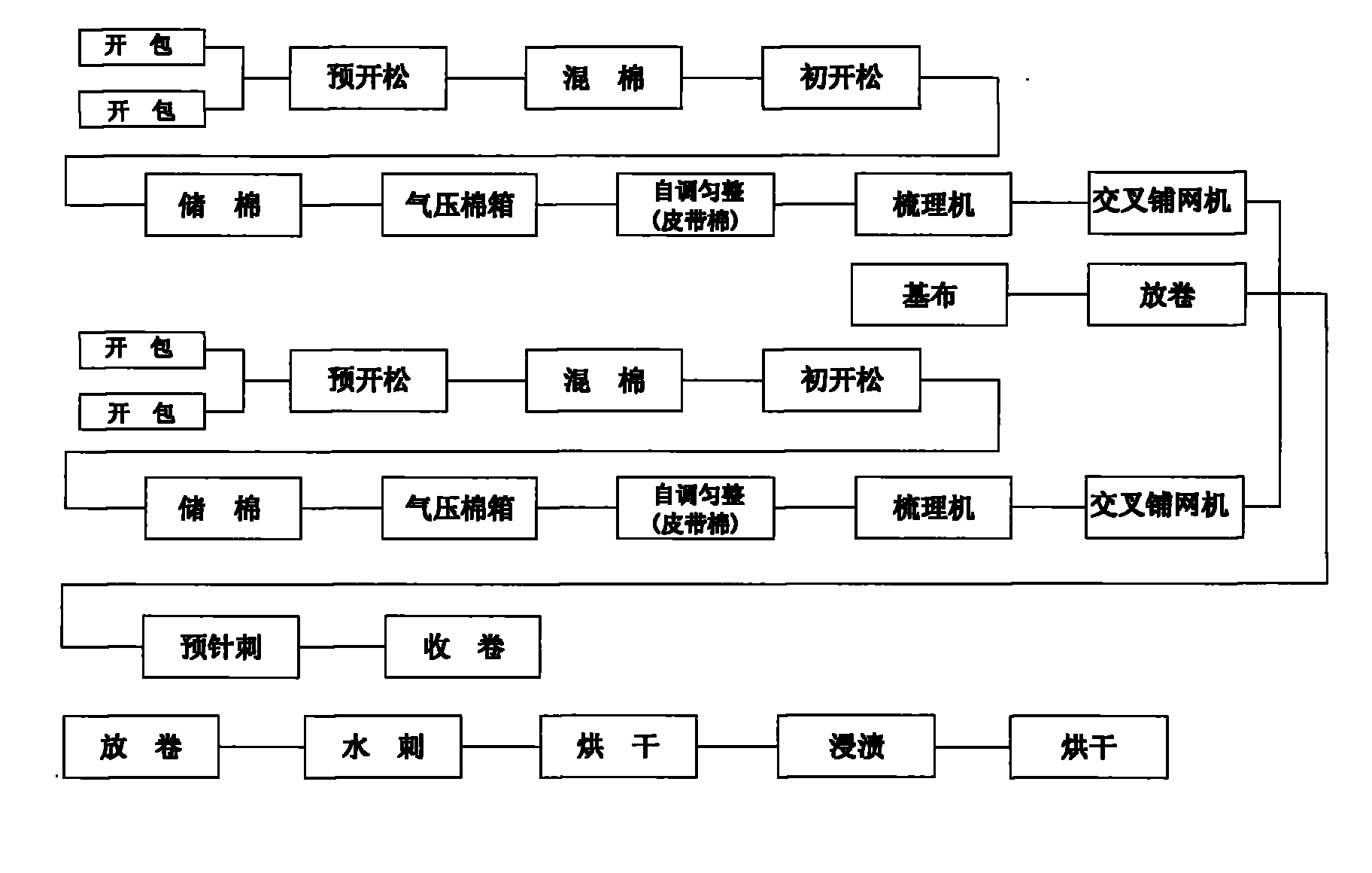

[0019] A kind of preparation method of special composite filter material for coal-fired power plant electric bag combined project according to the present invention, see figure 2 , the preparation method forms a plain felt through the composite process of needle punching and spunlace, and then impregnates it with a chemical solvent to make a special composite filter material for the coal-fired power plant electric bag integration project. The dust-facing surface of the obtained composite filter material is made of PTFE fiber and PPS fiber blending, in which the weight ratio of PTFE fiber is 30-70%; the base fabric is made of 100% PTFE filament interwoven in warp and weft; the bottom layer is made of PTFE fiber and PPS fiber blending, in which the weight ratio of PTFE fiber is 30- 70%; the specific steps are as follows:

[0020] 1) First, pre-open the PTFE fiber and PPS fiber, and then perform the initial opening;

[0021] 2) then combing the opened composite fibers and then ...

Embodiment 1

[0027] 2.2dtex PTFE fibers and 2.2dtexPPS fibers are mixed on the dust-facing surface to obtain composite fibers, in which the proportion of PTFE fibers is 30%; 2 ;The bottom layer is 100% 2.2dtexPPS fiber; as above figure 2 It is processed by advanced processing technology and made into a special composite filter material for coal-fired power plant electric bag combination project. Wherein the chemical solvent is prepared from PTFE emulsion and water, the solid content of the PTFE emulsion is 60%, and the weight percentage of PTFE in the modified solvent is 10%.

[0028] The warp and weft tensile strength of the special composite filter material for coal-fired power plant electric bag combined with the project prepared by the present invention exceeds 1200N / 5*20cm, which is 20% stronger than the 100%PPS filter material prepared by the acupuncture method, especially The fracture strength in the warp direction is increased by nearly 50%, and the fracture strength in the warp ...

Embodiment 2

[0030] 2.2dtex PTFE fibers and 2.2dtexPPS fibers are mixed on the dust-facing surface to obtain composite fibers, in which the proportion of PTFE fibers is 50%; 2 ;The bottom layer is 100% 2.2dtexPPS fiber; as above figure 2 It is processed by advanced processing technology to make a special composite filter material for coal-fired power plant electric bag combination project; the chemical solvent is made of PTFE emulsion and water, the solid content of PTFE emulsion is 60%, and the weight percentage of PTFE in the modified solvent is 15%.

[0031] The warp and weft tensile strength of the special composite filter material for coal-fired power plant electric bag combined with the project prepared by the present invention exceeds 1200N / 5*20cm, which is 20% stronger than the 100%PPS filter material prepared by the acupuncture method, especially The fracture strength in the warp direction is increased by nearly 50%, and the fracture strength in the warp and weft directions is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com