Mute water discharging pipe

A drainage pipe and silent technology, which is applied in water supply installations, indoor sanitary pipe installations, buildings, etc., can solve the problems of poor high temperature resistance and chemical corrosion resistance, large noise of drainage pipes, and unsatisfactory effect, etc., and achieves mechanical performance. Excellent, saving pipe fittings, excellent mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

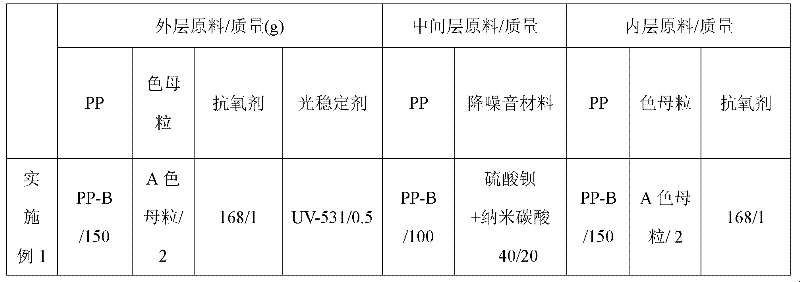

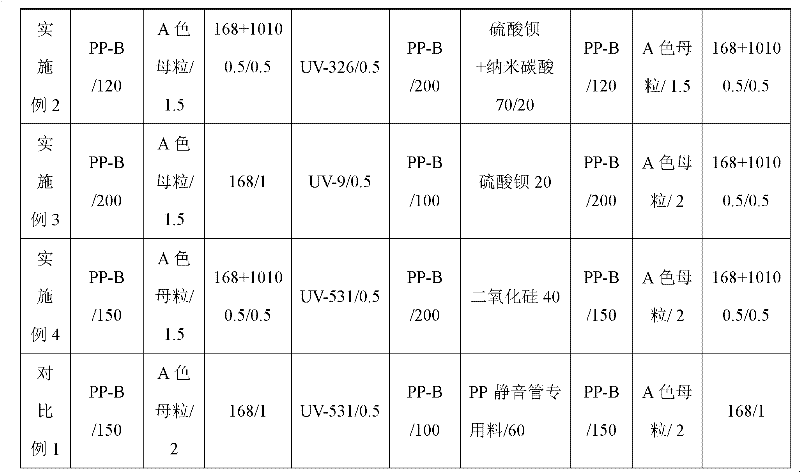

[0039] The ratio of raw materials for the preparation of the three-layer polypropylene silent drainage pipe of the present invention is shown in Table 1, wherein the performance index of the block copolymerized polypropylene is as follows: the density of the resin is 0.895~0.910g / cm 3, Melt index (230°C / 2.16kg): 1.8±0.2g / 10min, Izod impact strength not less than 93J / M, Rockwell hardness not less than 85R, flexural modulus not less than 1100MPa. In addition, the present invention also makes comparative example 1 aiming at using PP special material for silent pipe as the middle sound-absorbing layer, and other conditions are the same as that of Example 1, and its raw material ratio is shown in Table 1.

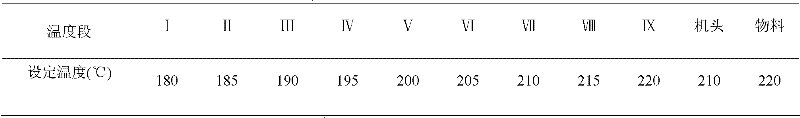

[0040] The present invention adopts the method for three-layer co-extrusion to prepare the polypropylene silent drainage pipe, and the specific steps are:

[0041] (1) Melt and blend polypropylene resin and noise-absorbing material at a temperature of 80°C to obtain an intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com