Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

A technology for concrete mortar and waterproofing membrane, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of poor water resistance, ultraviolet aging resistance, poor aging resistance, and increased production costs of cement-based particle isolation layers. , to eliminate the problem of UV aging, good water resistance, excellent weather resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

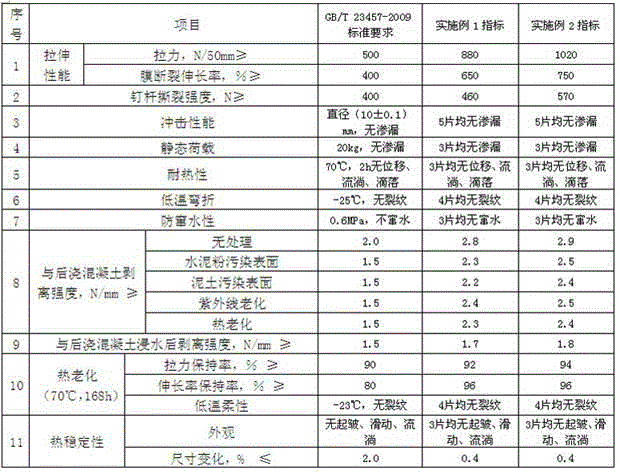

Examples

Embodiment 1

[0048] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0049] First, 70 parts of high-density polyethylene resin, 30 parts of linear low-density polyethylene resin, 10 parts of thermoplastic elastomer resin, 0.5 part of antioxidant 1010, 0.5 part of antioxidant 168 and 2 parts of titanium dioxide are added to the mixer, Mix and stir for 5 minutes; then add the mixture into a single-screw extruder, and extrude a modified polyethylene plastic waterproof main layer diaphragm with a thickness of 0.8 mm. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0050] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0051] First, add 15 parts of naphthenic white oil, 20 parts of polyisobutylene, 0.5 part of antioxidant 1010, 0.5 part of antioxidant 168 and 45 parts of petroleum resin with a soft...

Embodiment 2

[0056] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0057] First, 90 parts of high-density polyethylene resin, 30 parts of linear low-density polyethylene resin, 20 parts of thermoplastic elastomer resin, 0.8 part of antioxidant 1010, 1.2 parts of antioxidant 168 and 4 parts of titanium dioxide are added to the mixer, Mix and stir for 5 minutes; then add the mixture into a single-screw extruder, and extrude a modified polyethylene plastic waterproof main layer diaphragm with a thickness of 1.0 mm. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0058] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0059] First, add 30 parts of naphthenic white oil, 30 parts of polyisobutylene, 0.8 parts of antioxidant 1010, 1.2 parts of antioxidant 168, and 50 parts of petroleum resin with a ...

Embodiment 3

[0066] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0067] First, add 60 parts of high-density polyethylene resin, 10 parts of linear low-density polyethylene resin, 0.5 part of antioxidant 1010 and 1 part of titanium dioxide into the mixer, mix and stir for 5 minutes; then add the mixture to the single-screw extruder In the exiting machine, a modified polyethylene plastic waterproof main layer membrane with a thickness of 1.0mm is extruded. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0068] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0069] First, add 10 parts of naphthenic white oil, 10 parts of polyisobutylene, 0.5 parts of antioxidant 168 and 30 parts of petroleum resin with a softening point of 110°C into a reactor with a stirring device and mix when the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com