Geopolymer chemically-bonded ceramic tile and preparation method thereof

A technology for chemically bonding ceramics and geopolymers. It is applied in the production of ceramic materials, clay products, and other household appliances. It can solve problems such as aggravating the greenhouse effect and affecting the natural environment, and achieve huge market value, low cost and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

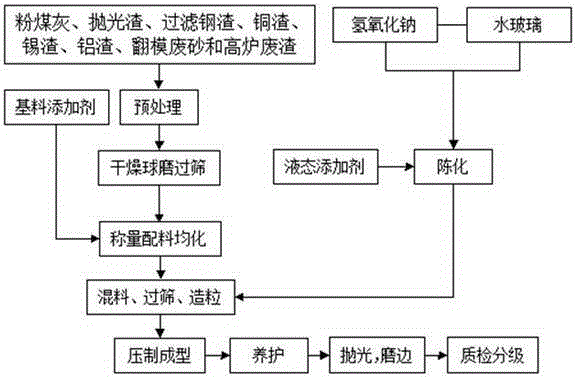

[0025] A preparation method of geopolymer chemically bonded ceramic wall and floor tiles, comprising the following steps:

[0026] Step 1: Raw material pretreatment: Homogenize the fly ash, remove impurities and pretreat it for later use;

[0027] Step 2: Flour making: dry the pretreated fly ash at 110°C, dry ball mill until it passes through a 150 mesh sieve, and the sieve residue is less than 0.5%;

[0028] Step 3: Compound liquid activator preparation: mix 4g of sodium hydroxide, 19g of water glass with a modulus of 1.0, and 1g of potassium hydroxide, and place it for aging for 24 hours;

[0029] Step 4: Uniform mixing, sieving and granulation: 74g of fly ash, CaCl 2 2g, after mixing evenly, add the compound liquid activator prepared in step 3, mix evenly and then granulate;

[0030] Step 5: Press molding: add the powder obtained in step 4 into the press, compact it under a pressure of 40MP, and hold the pressure for 16s to obtain a semi-finished chemically bonded ceramic...

Embodiment 2

[0034] A preparation method of geopolymer chemically bonded ceramic wall and floor tiles, comprising the following steps:

[0035] Step 1: Pretreatment of raw materials: Homogenize fly ash and polishing slag, remove impurities and other pretreatments;

[0036] Step 2: Flour making: dry the pretreated fly ash and polishing slag at 110°C, then dry ball mill to pass through a 150-mesh sieve, and the sieve residue is less than 0.5%;

[0037] Step 3: Composite liquid activator preparation: mix 5g of sodium hydroxide, 4g of water glass with a modulus of 1.5, 0.5g of potassium hydroxide, and 0.5g of lithium hydroxide, and place it for aging for 35 hours;

[0038] Step 4: Uniform mixing, sieving and granulation: Mix 34g of fly ash, 34g of polishing slag, CaO1g, and MgO1g, and then add the compound liquid activator prepared in step 3, and then granulate after mixing evenly;

[0039] Step 5: Press molding: put the powder obtained in step 4 into the press, compact it under a pressure of...

Embodiment 3

[0043] A preparation method of geopolymer chemically bonded ceramic wall and floor tiles, comprising the following steps:

[0044]Step 1: Pretreatment of raw materials: Homogenize fly ash, polishing slag, and filtered steel slag, remove impurities and other pretreatments;

[0045] Step 2: Flour making: dry the pretreated fly ash, polishing slag, and filter steel slag at 110°C, then dry ball mill until they pass through a 200-mesh sieve, and the sieve residue is less than 0.5%;

[0046] Step 3: Composite liquid activator preparation: mix 5g of sodium hydroxide, 26g of water glass with a modulus of 2.0, and 1g of potassium hydroxide, and place it for aging for 40 hours;

[0047] Step 4: Uniform mixing, sieving and granulation: 30g of fly ash, 30g of polishing slag, 5g of filtered steel slag, CaO1g, MgO1g, Na 2 SO 4 1g, after mixing evenly, add the compound liquid activator prepared in step 3, mix evenly and then granulate;

[0048] Step 5: Compression molding: add the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com