Copper-plated carbon nanotube reinforced pantograph pan material and preparation method thereof

A technology of pantograph slides and nanotubes, applied in the field of materials, can solve problems such as large wire wear, increased maintenance costs, pantograph-catenary accidents, etc., and achieve the effects of improved mechanical properties, long service life, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

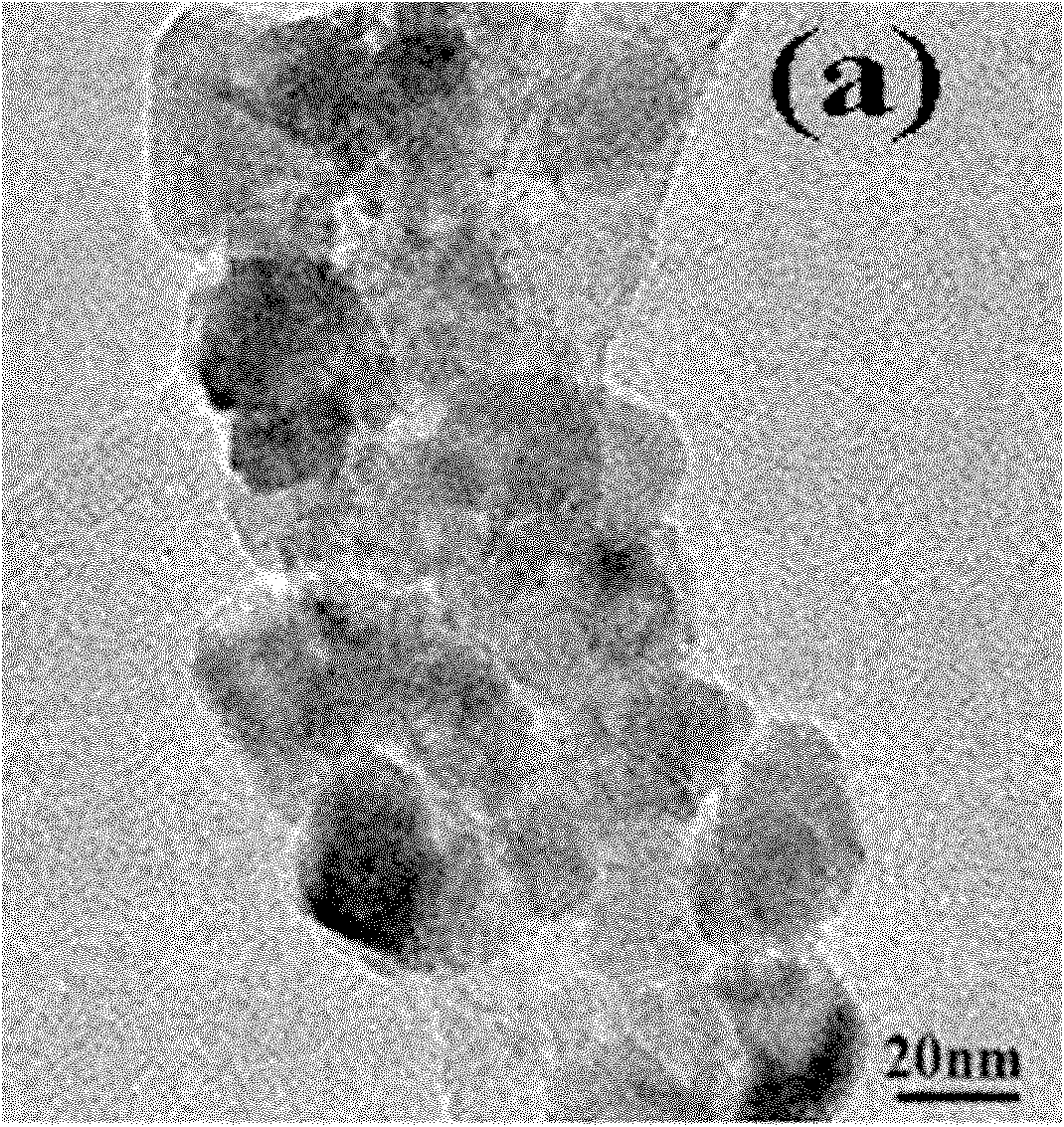

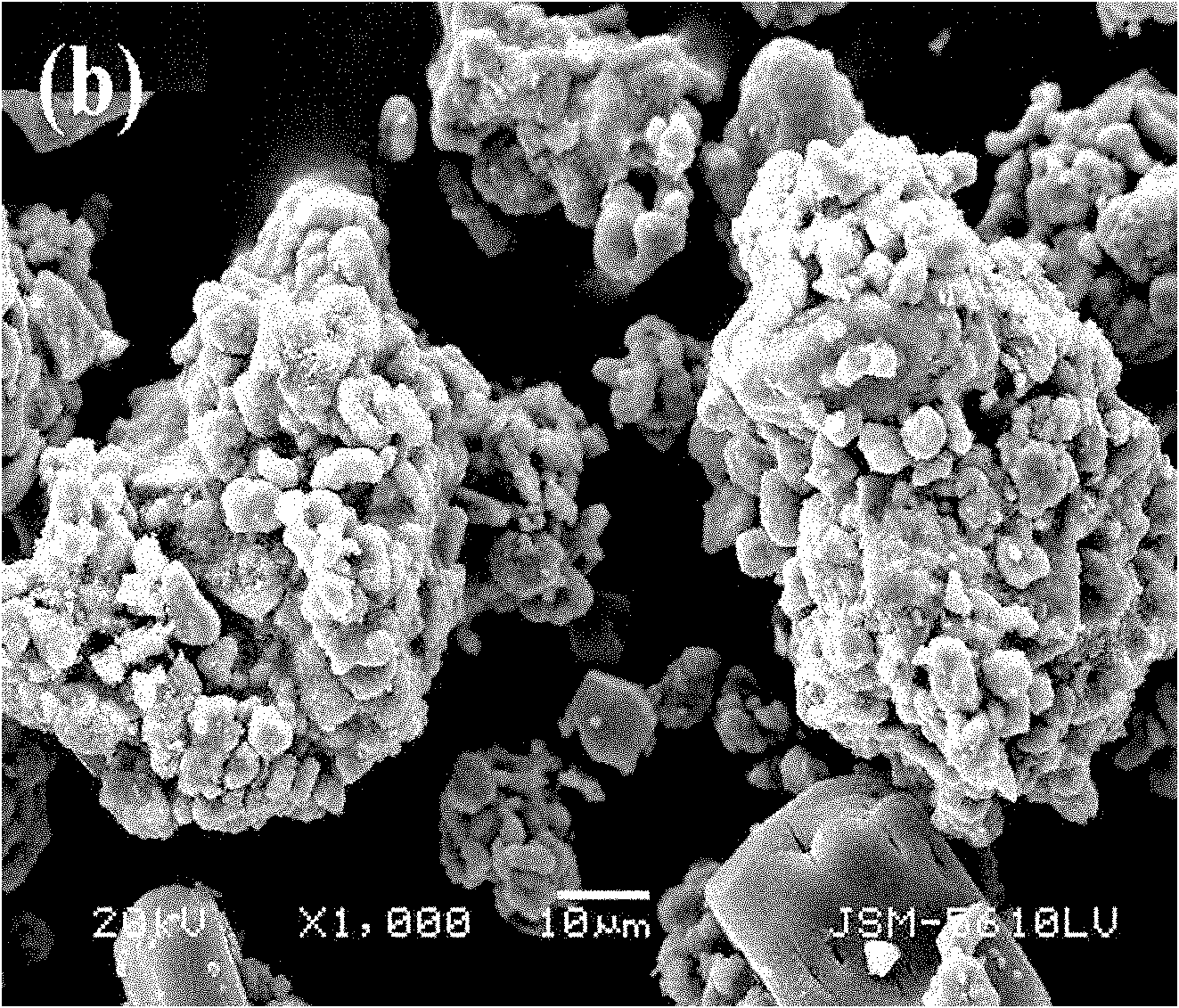

Image

Examples

Embodiment 1

[0043] Each component in the plating solution is Wt(H 2 O): Wt(CuSO 4 ): Wt(C 10 h 14 N 2 Na 2 o 3 ): Wt(C 10 h 8 N 2 ): Wt(NaOH): Wt(CH 2 (O)=94: 2: 1: 0.2: 0.6: 2.2, plating for 0.5 hours, the volume ratio of the reinforcing agent and modifier powder after plating to the matrix copper is V(Cu): V(CNTs): V (Ti 3 SiC 2 ): V(TiB 2 )= 65:5:10:20, after dry mixing for 1 hour, use glycerin as the mixing medium, mix evenly for 4~6 hours and dry, add an appropriate amount of binder, put it into a steel mold, and cold press it , the pressure is 100MPa, sintering is carried out under the protection of hydrogen atmosphere, the heating rate is 20°C / min, the sintering temperature is 750°C, and the heat preservation is 30 minutes. After that, the sample is taken out, placed in the mold, and the second cold pressing is carried out, and the pressure is 150MPa , Under the protection of hydrogen atmosphere, the secondary sintering is carried out, the heating rate is 20°C / min, the...

Embodiment 2

[0046] Each component in the plating solution is Wt(H 2 O): Wt(CuSO 4 ): Wt(C 10 h 14 N 2 Na 2 o 3 ): Wt(C 10 h 8 N 2 ): Wt(NaOH): Wt(CH 2 (O)=92: 3: 1.5: 0.3: 0.7: 3.5, after plating for 1 hour, the volume ratio of the strengthener and modifier powder after plating to the matrix copper is V(Cu):V(CNTs):V (Ti 3 SiC 2 ) : V(TiB 2 )=70:6:20:4, after dry mixing for 1 hour, use glycerol as the mixing medium, mix evenly for 4~6 hours and dry, add an appropriate amount of binder, put it into a steel mold, and cold press , the pressure is 100MPa, sintering is carried out under the protection of hydrogen atmosphere, the heating rate is 20°C / min, the sintering temperature is 750°C, and the heat preservation is 30 minutes. After that, the sample is taken out, placed in the mold, and the second cold pressing is carried out, and the pressure is 150MPa , under the protection of hydrogen atmosphere, the second sintering is carried out, the heating rate is 20°C / min, the sinterin...

Embodiment 3

[0049] Each component in the plating solution is Wt(H 2 O): Wt(CuSO 4 ): Wt(C 10 h 14 N 2 Na 2 o 3 ): Wt(C 10 h 8 N 2 ): Wt(NaOH): Wt(CH 2 (O)=90: 5: 2: 0.5: 0.7: 1.8, after plating for 2 hours, the volume ratio of the strengthener and modifier powder after plating to the matrix copper is V(Cu):V(CNTs):V (Ti 3 SiC2) : V(TiB 2)= 75:8:15:2, after dry mixing for 1 hour, use glycerol as the mixing medium, mix evenly for 4~6 hours and dry, add an appropriate amount of binder, put it into a steel mold, and cold press , the pressure is 100MPa, sintering is carried out under the protection of hydrogen atmosphere, the heating rate is 20°C / min, the sintering temperature is 750°C, and the heat preservation is 30 minutes, then take out the sample, place it in the mold, and carry out secondary cold pressing at a pressure of 150MPa , carry out secondary sintering under the protection of hydrogen atmosphere, the heating rate is 20°C / min, the sintering temperature is 850°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com