Surface corrosion of CdTe film and CdTe solar cell preparing by the process

A technology of solar cells and thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as toxicity, unfavorable industrial production, and preferential corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

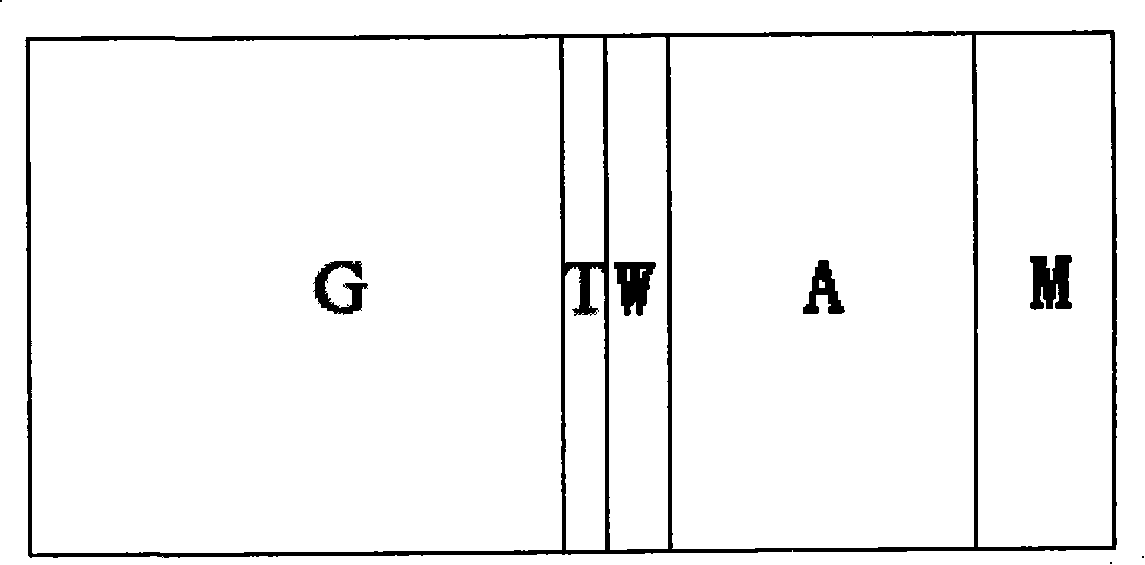

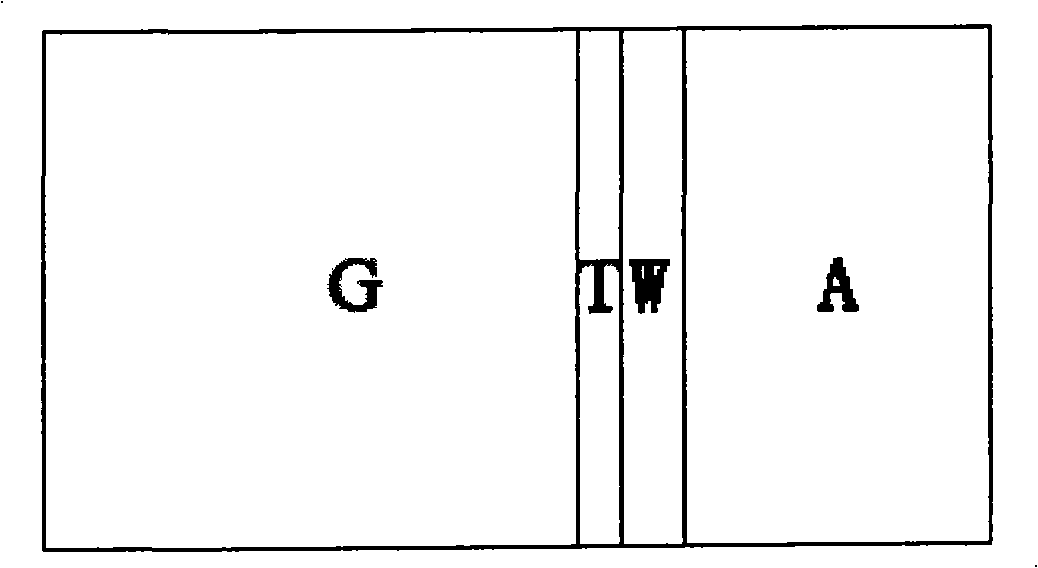

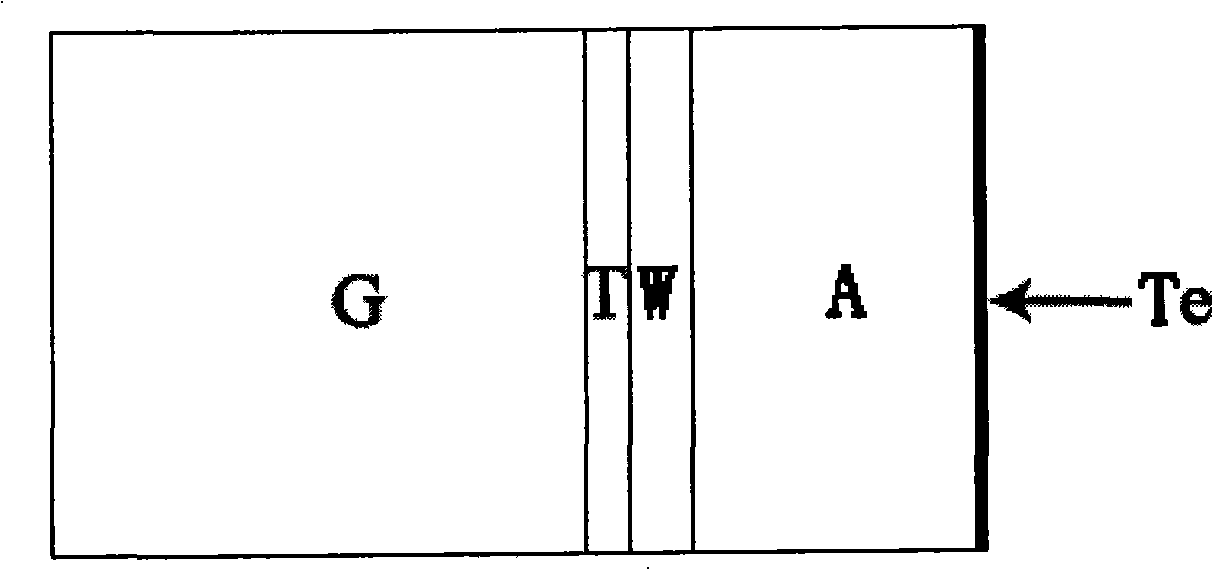

Image

Examples

Embodiment 1

[0016] (1) When the temperature of the corrosive solution is controlled at 40°C, the sample is put into the corrosive solution, and the corrosive solution is 65% to 68% nitric acid, 99.5% glacial acetic acid and deionized water in a ratio of 1: 100:40 volume ratio mixing, the added NaAc is 15g / L, and the corrosion time is 1 minute.

[0017] (2) Take out the sample, rinse it several times with deionized water, and dry it with nitrogen.

[0018] (3) Co-sputter high-purity ZnTe target (99.999%) and Cu target (99.999%) by sputtering method or vacuum co-evaporation method to evaporate high-purity ZnTe source (99.999%) and copper source (99.999%), the deposition thickness is about 100nm, annealed at ~190°C, and then deposited ~200nm metal electrode Ni.

Embodiment 2

[0020] (1) When the temperature of the corrosive solution is controlled at 35°C, the sample is put into the corrosive solution, and the corrosive solution is 65% to 68% nitric acid, 99.5% glacial acetic acid and deionized water in a ratio of 1: 100:30 volume ratio mixing, the added NaAc is 15g / L, and the corrosion time is 2 minutes.

[0021] (2) Take out the sample, rinse it several times with deionized water, and dry it with nitrogen.

[0022] (3) Coat the surface of the corroded CdTe with 10% HgTe:Cu / 90% graphite slurry, anneal in nitrogen for 20 minutes at a temperature of 290° C., and then deposit 100 nm of Au as a metal electrode.

Embodiment 3

[0024] (1) When the temperature of the corrosive solution is controlled at 30°C, the sample is put into the corrosive solution, and the corrosive solution is 65% to 68% nitric acid, 99.5% glacial acetic acid and deionized water with a ratio of 1.5: 100:30 volume ratio mixing, the added NaAc is 20g / L, and the corrosion time is 3 minutes.

[0025] (2) Take out the sample, rinse it several times with deionized water, and dry it with nitrogen.

[0026] (3) co-sputtering high-purity Sb target (99.999%) and Te target (99.999%) by sputtering method or vacuum co-evaporation method to evaporate high-purity Sb source (99.999%) and Te source (99.999%), the deposition rate ratio (0.4~0.7), the thickness is about 100nm, annealed to 200°C, and Ni / Al electrode (Ni: 50nm; Al: 3μm) is deposited.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com